A high-efficiency egr introduction hybrid system

A mixing system and EGR valve technology, applied in the direction of charging system, electrical control, machine/engine, etc., can solve the problems of reduced engine efficiency, high EGR flow resistance, uneven EGR mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

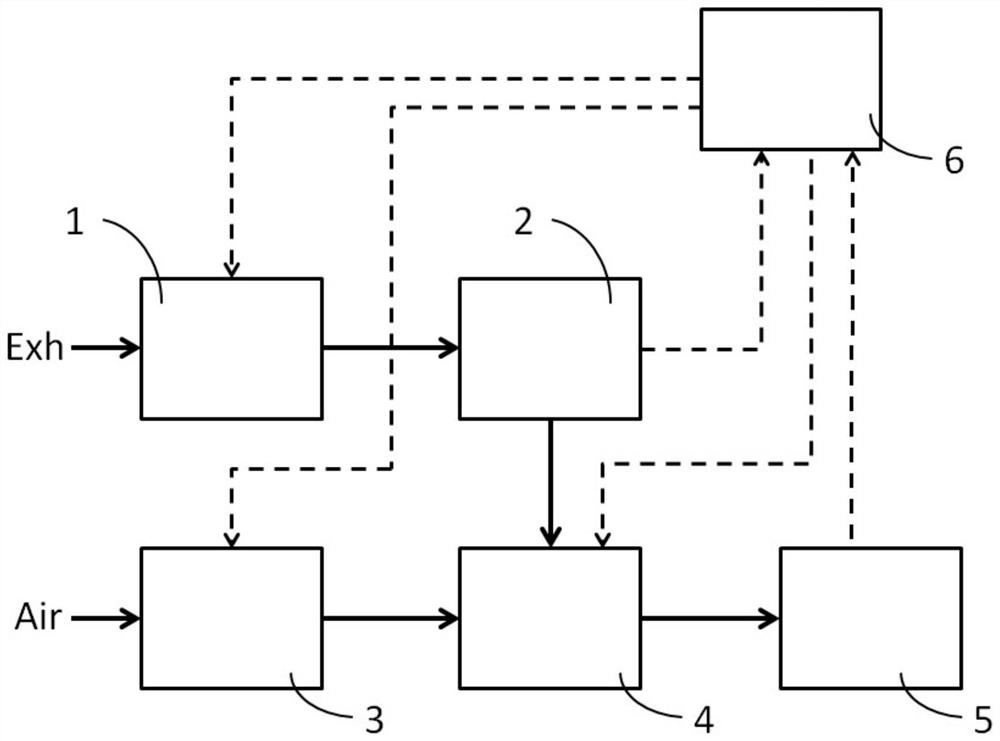

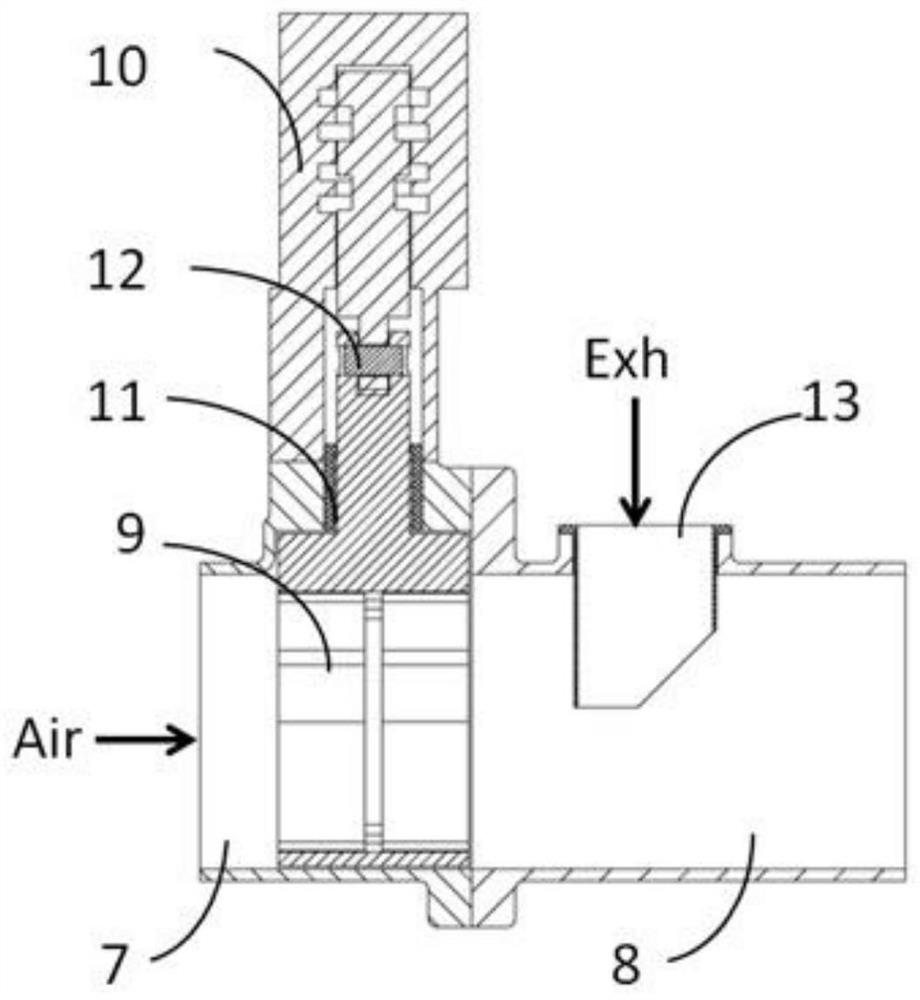

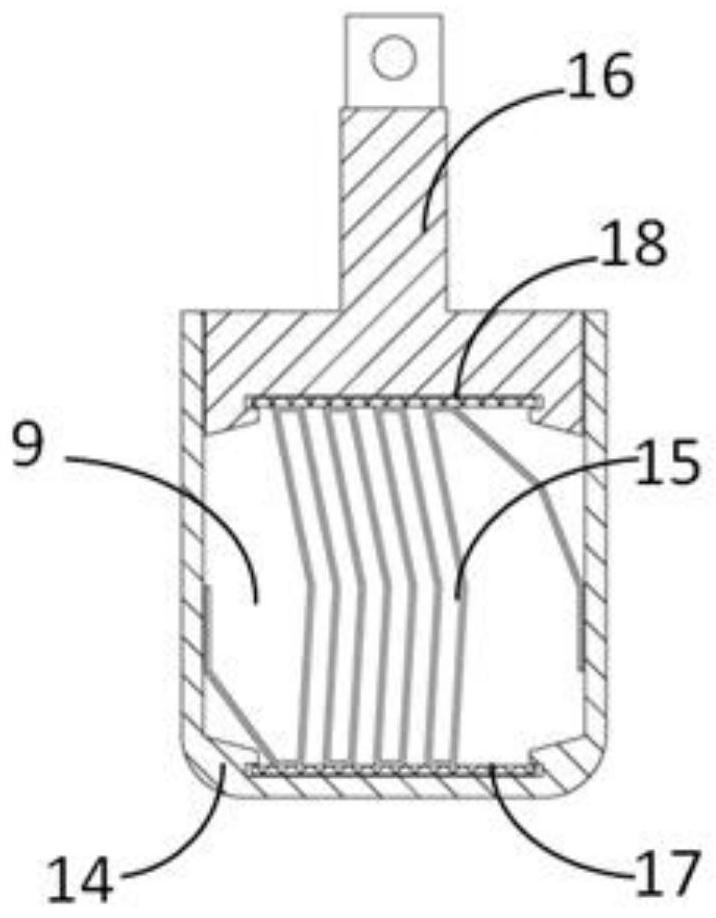

[0016] refer to figure 1 , a high-efficiency EGR introduction hybrid system, including EGR valve 1, venturi tube sensor 2, intake throttle valve 3, mixer 4, intake air temperature and pressure sensor 5, ECU6 and other components.

[0017] The EGR valve 1 is controlled by the ECU6, and its main function is to control the flow of exhaust gas. The main function of Wen Qiuli tube sensor 2 is to measure the flow rate of exhaust gas and send the data to ECU6 at the same time. The intake throttle valve 3 is controlled by the ECU6, and its main function is to control the air flow. Mixer 4 is controlled by ECU6, and its main function is to mix air and exhaust gas. The main function of the intake air temperature and pressure sensor 5 is to measure the pressure and temperature of the mixture, and send the data to the ECU 6 at the same time. ECU6 is the engine control unit, its function is to receive the signals from venturi tube sensor 2 and intake air temperature and pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com