Automatic coring and stringing device for hawthorns

A hawthorn, automatic technology, applied in the field of hawthorn automatic de-pitting and clustering device, can solve the problems of low production efficiency, easy to stab hands, time-consuming and other problems, and achieve the effects of improving production efficiency, reducing manpower input, and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

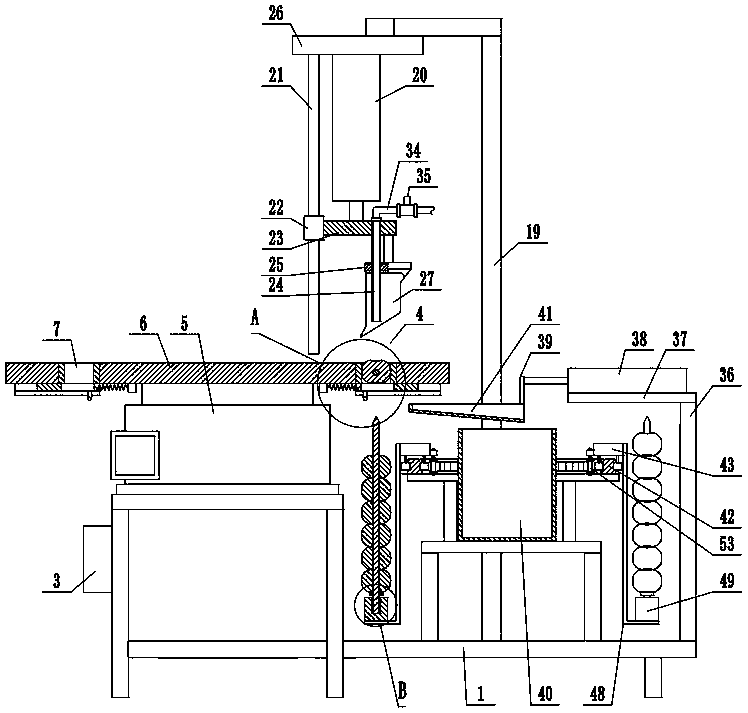

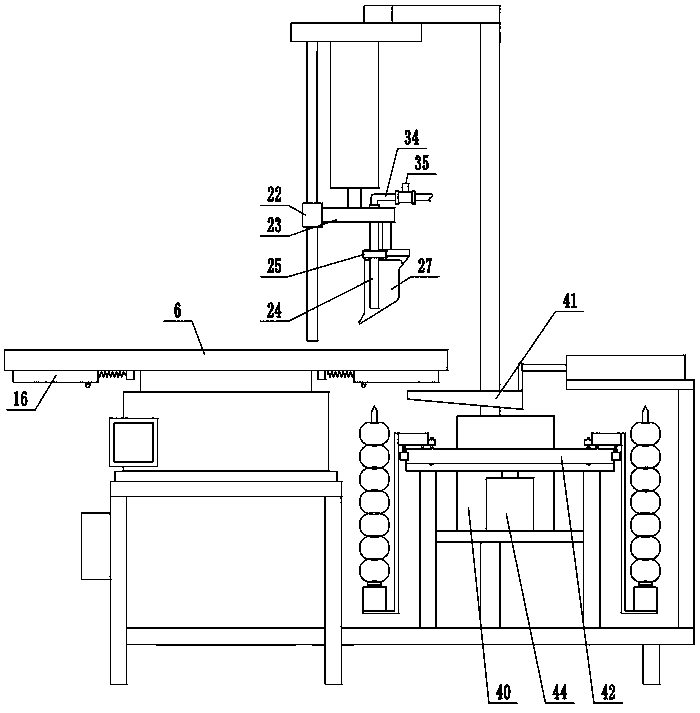

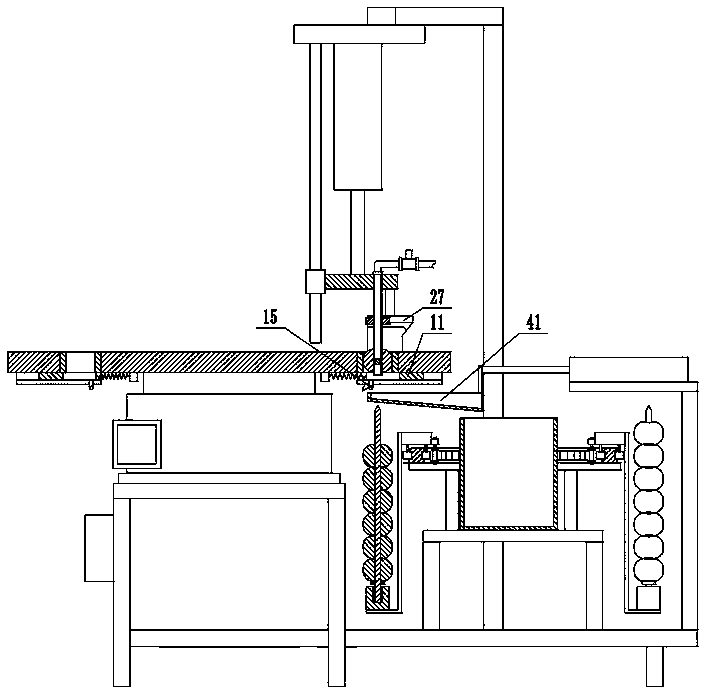

[0029] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-13Shown: a kind of hawthorn automatic denuclearization stringing device, comprises frame 1 and candied haws sign 2, controller 3 is installed on the frame 1, has denuclear station 4 on the frame 1, is provided with for Transport the candied haws 2 one by one to the conveying mechanism below the nuclear removal station 4, the turntable mechanism for transporting the hawthorns 9 to the nuclear removal station 4 one by one, and the mechanism for removing the nucleus of the hawthorn 9 at the nuclear removal station 4. The nuclear mechanism; the turntable mechanism includes an electric turntable 5 and a rotating disk 6. The electric turntable 5 is installed on the frame 1, and the turntable 6 is installed on the rotating end face of the electric turntable 5. The upper end face of the turntable 6 is provided with a plurality of The first opening 7 and the second openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com