Method for preparing multi-channel antibacterial nerve guide by variable spindle braiding method

A nerve conduit and multi-channel technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of poor mechanical properties, easy deformation and tearing, high cost, etc., and achieve good mechanical properties, ideal tensile strength, bending Good deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

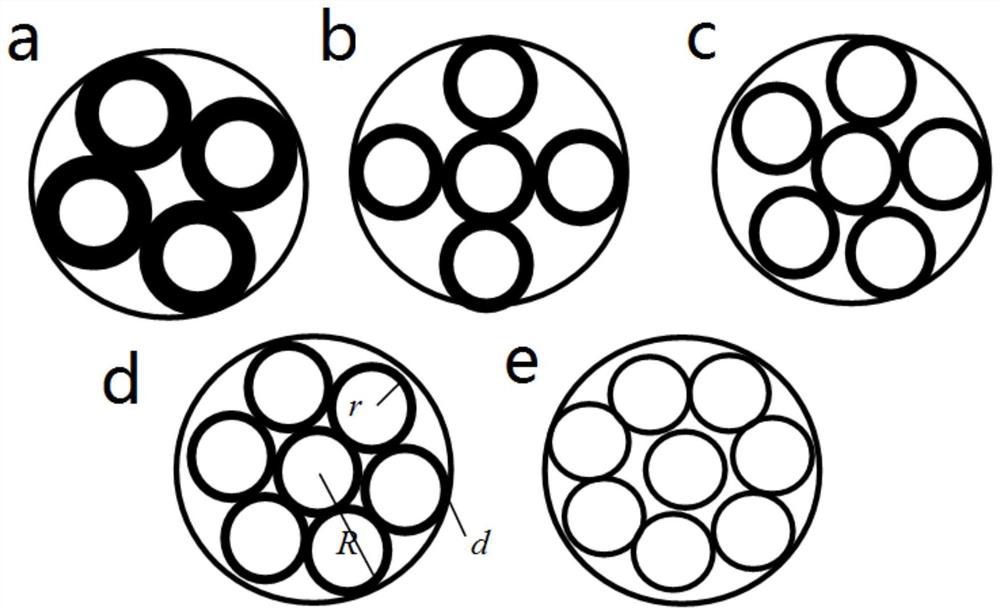

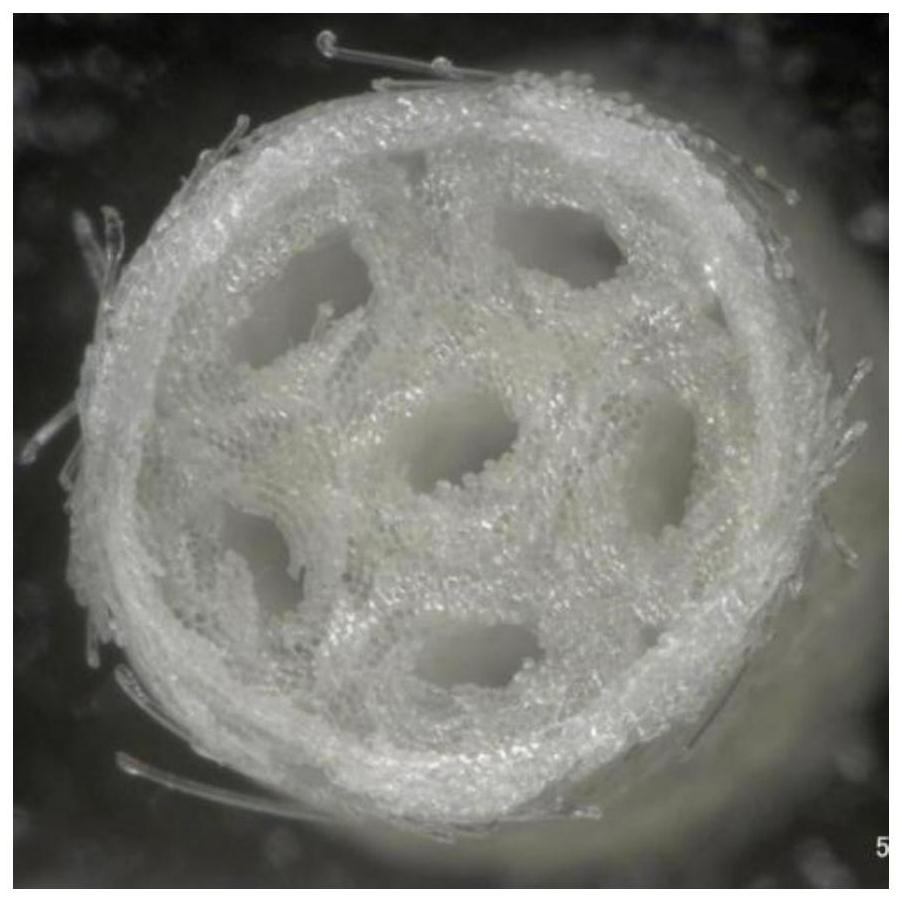

[0049] This embodiment provides a method for preparing a 6-channel antibacterial artificial nerve guide, using polylactic acid (PLA) yarn as the braiding yarn, and using a 16-spindle braiding machine as a tool, the specific steps are as follows:

[0050] 1. Determine the design parameters of the nerve guide: select white polylactic acid (PLA) yarns with a diameter of 120 μm as the braided yarn of the inner catheter and the braided yarn of the outer catheter (d y =120 μm), diameter is the black polypropylene (PP) monofilament of 600 μm as inner core material (r=300 μm), the internal diameter R of the prepared antibacterial artificial nerve guide is 0.9mm, channel number n is 6, k=0.83, λ=0.87, substitute these parameters into the formula Calculated to give m = 12.2. That is, 12 spindles are selected for weaving.

[0051] 2. Preparation of the knitting machine: use a 12-spindle knitting machine, and lift the excess spindles with rubber bands without threading yarn.

[0052] ...

Embodiment 2

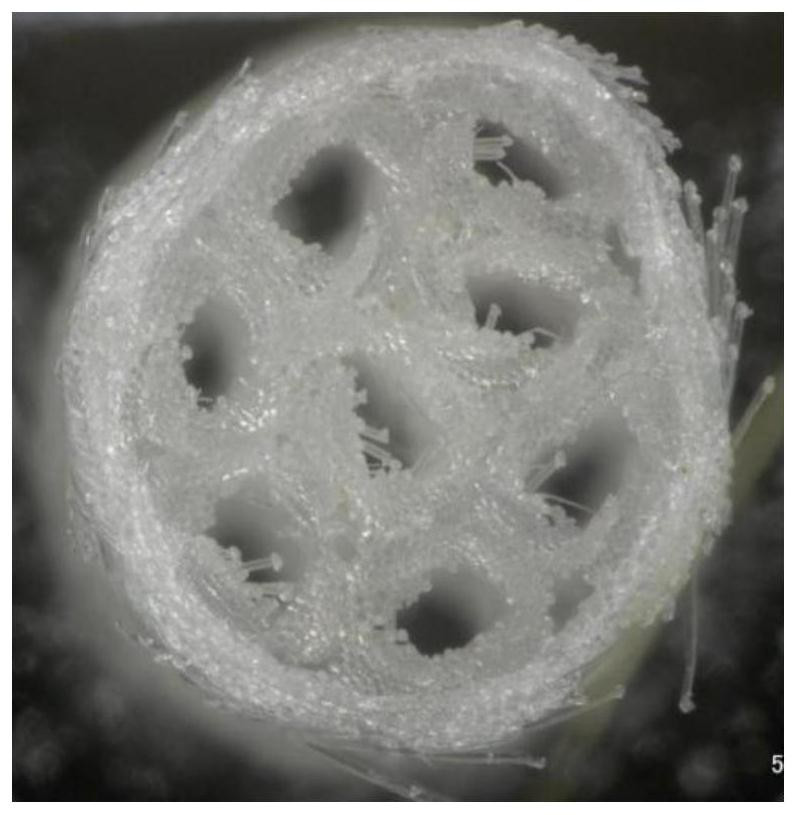

[0064]This embodiment provides a method for preparing an 8-channel antibacterial artificial nerve guide, using polylactic acid (PLA) yarn as the braiding yarn, and using a 16-spindle braiding machine as a tool. The specific steps are as follows:

[0065] 1. Determine the design parameters of the nerve guide: select white polylactic acid (PLA) yarns with a diameter of 120 μm as the braided yarn of the inner catheter and the braided yarn of the outer catheter (d y =120 μm), the diameter is the black polypropylene (PP) monofilament of 600 μm as inner core material (r=300 μm), the internal diameter R of the prepared antibacterial artificial nerve guide is 0.9mm, channel number n is 8, k=0.87, λ=0.81, substitute these parameters into the formula Calculated to m = 8.07. That is to choose 8 spindles to weave.

[0066] 2. Preparation of knitting machine: use 8-spindle knitting machine, and lift the excess spindles with rubber bands without threading yarn.

[0067] 3. Braided cathe...

Embodiment 3

[0075] This embodiment provides a method for preparing a 6-channel antibacterial artificial nerve guide, using degummed 20 / 22 silk twisted yarn as the weaving yarn, and using a 16-spindle braiding machine as a tool. The specific steps are as follows:

[0076] 1. Determine the design parameters of the nerve conduit: select the degummed 20 / 22 silk twisted yarn with a diameter of 85 μm as the inner conduit braiding yarn and the outer conduit braiding yarn (d y =85 μm), the diameter is the black polypropylene (PP) monofilament of 600 μm as inner core material (r=300 μm), the internal diameter R of the prepared antibacterial artificial nerve guide is 0.85mm, channel number n is 8, k=0.87, λ=0.81, substitute these parameters into the formula Calculated to m = 16.08. That is, 16 spindles are selected for weaving.

[0077] 2. Braiding machine preparation: use a 16-spindle braiding machine, that is, all the spindles are used.

[0078] 3. Braided catheter: tightly weave 8 inner cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com