An intelligent perforation method for laser cutting and laser cutting equipment

A laser cutting, intelligent technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems affecting the use effect and stability, the operation interface setting parameters are many, the debugging process is complicated, etc., to achieve the operation interface setting parameters Less, improve processing stability, clear effect of logic editing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

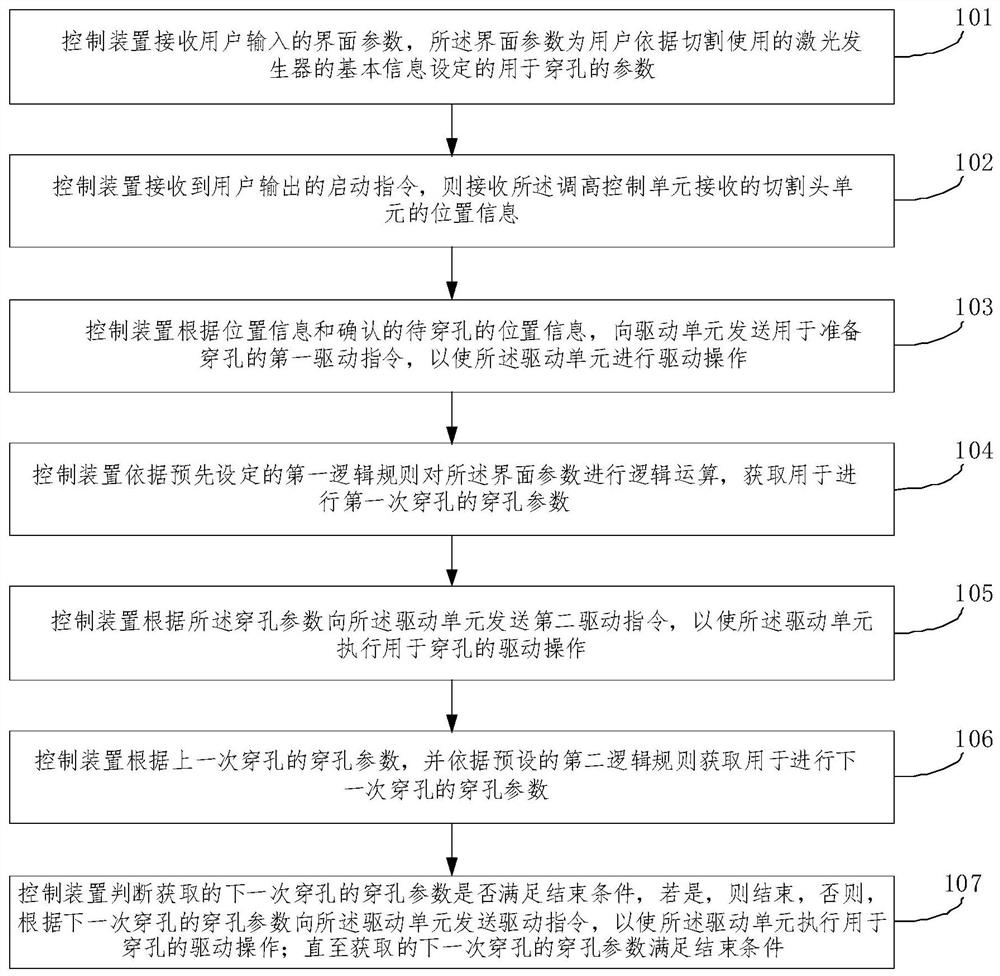

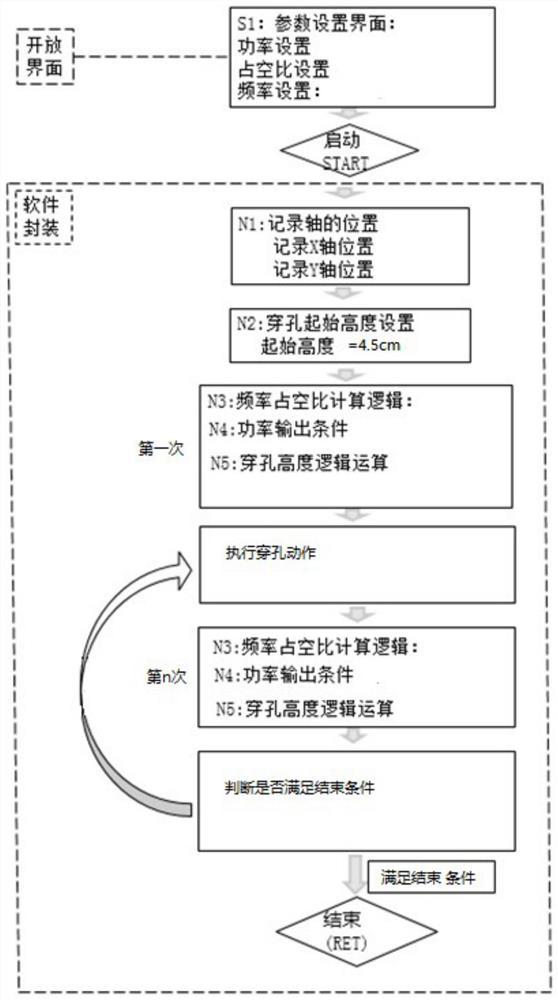

[0053] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0054] In order to better understand the solution of the embodiment of the present invention, the device of the embodiment of the present invention is briefly described below.

[0055] At present, the industry's requirements for cutting and piercing are not only to ensure the operation of the piercing process is convenient, the interface setting parameters are simple, but also to ensure efficiency and stability, so as to ensure a stable cutting effect in subsequent processing.

[0056] The embodiment of the present invention provides a piercing method with convenient operation, fewer parameter settings, faster use and more stable cutting.

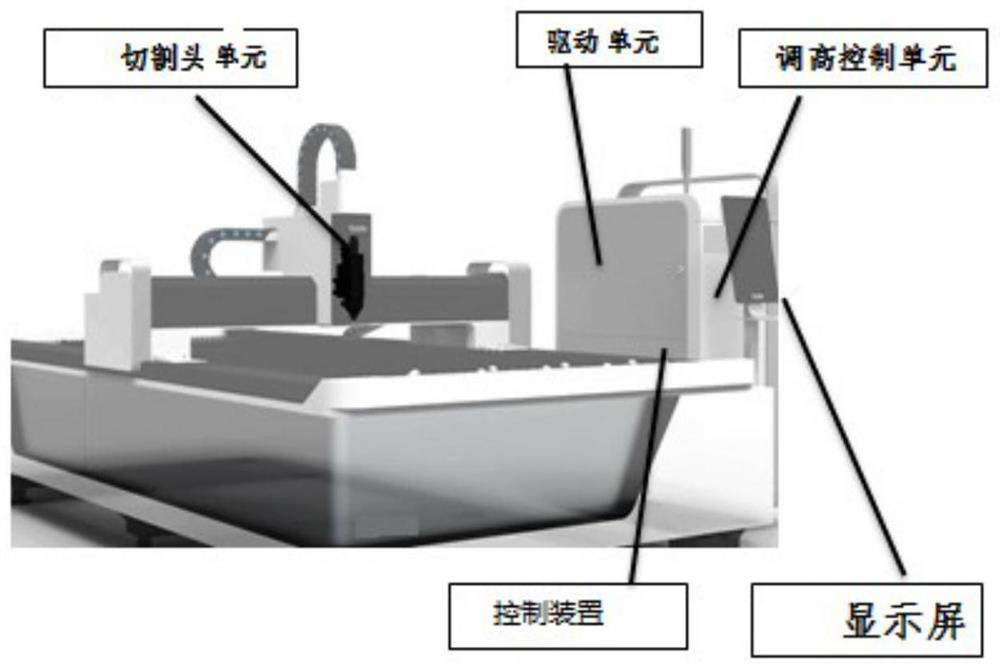

[0057] refer to figure 1 as shown, figure 1A structural schematic diagram of a laser cutting device is provided. The las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com