Vertical type polishing grinder

A grinding machine and vertical technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of high cost of fixture replacement, poor polishing environment, and non-universal fixtures, etc., to achieve high work efficiency and save Replacing the abrasive and the time of the workpiece, the effect of the polishing effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

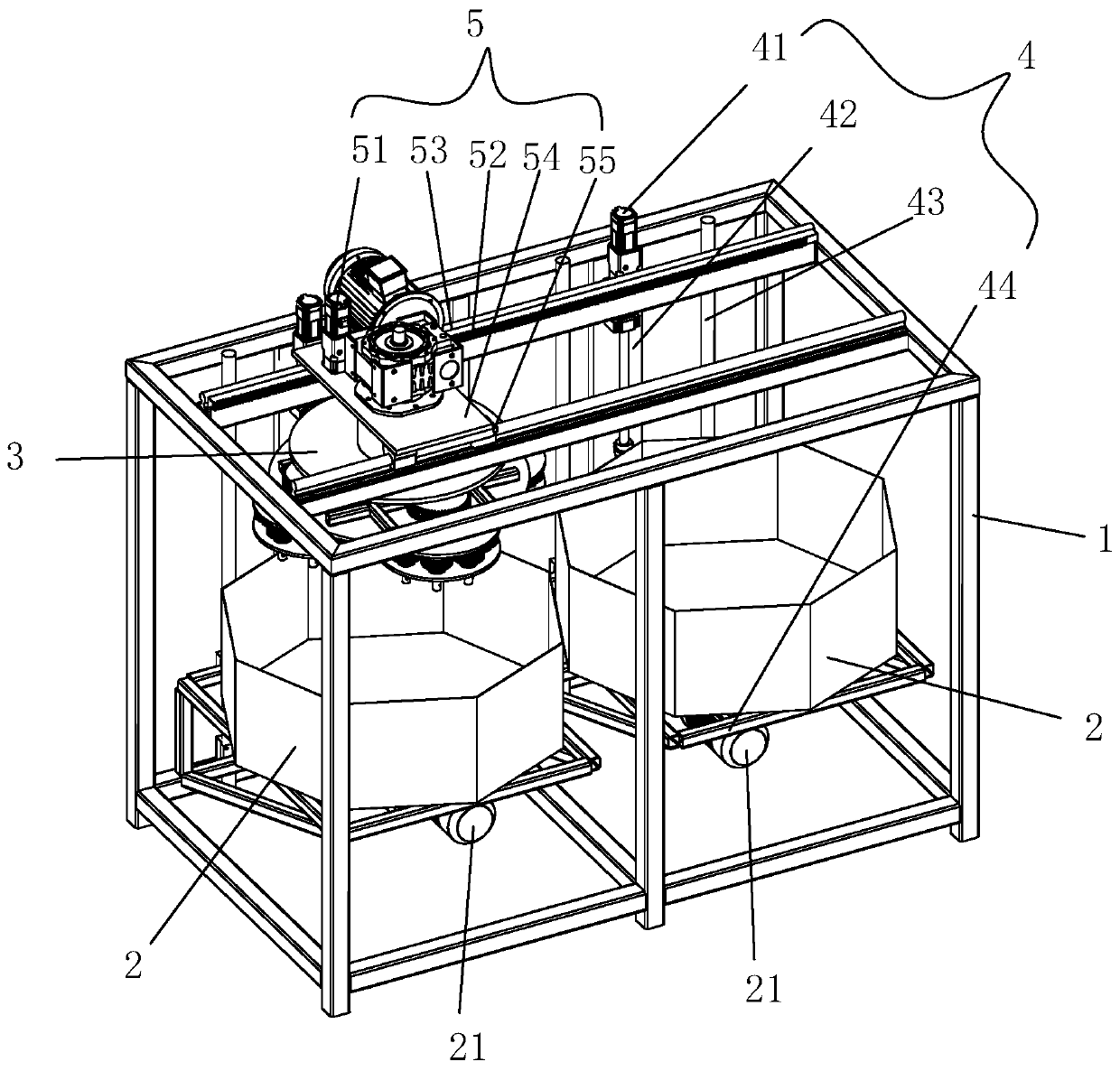

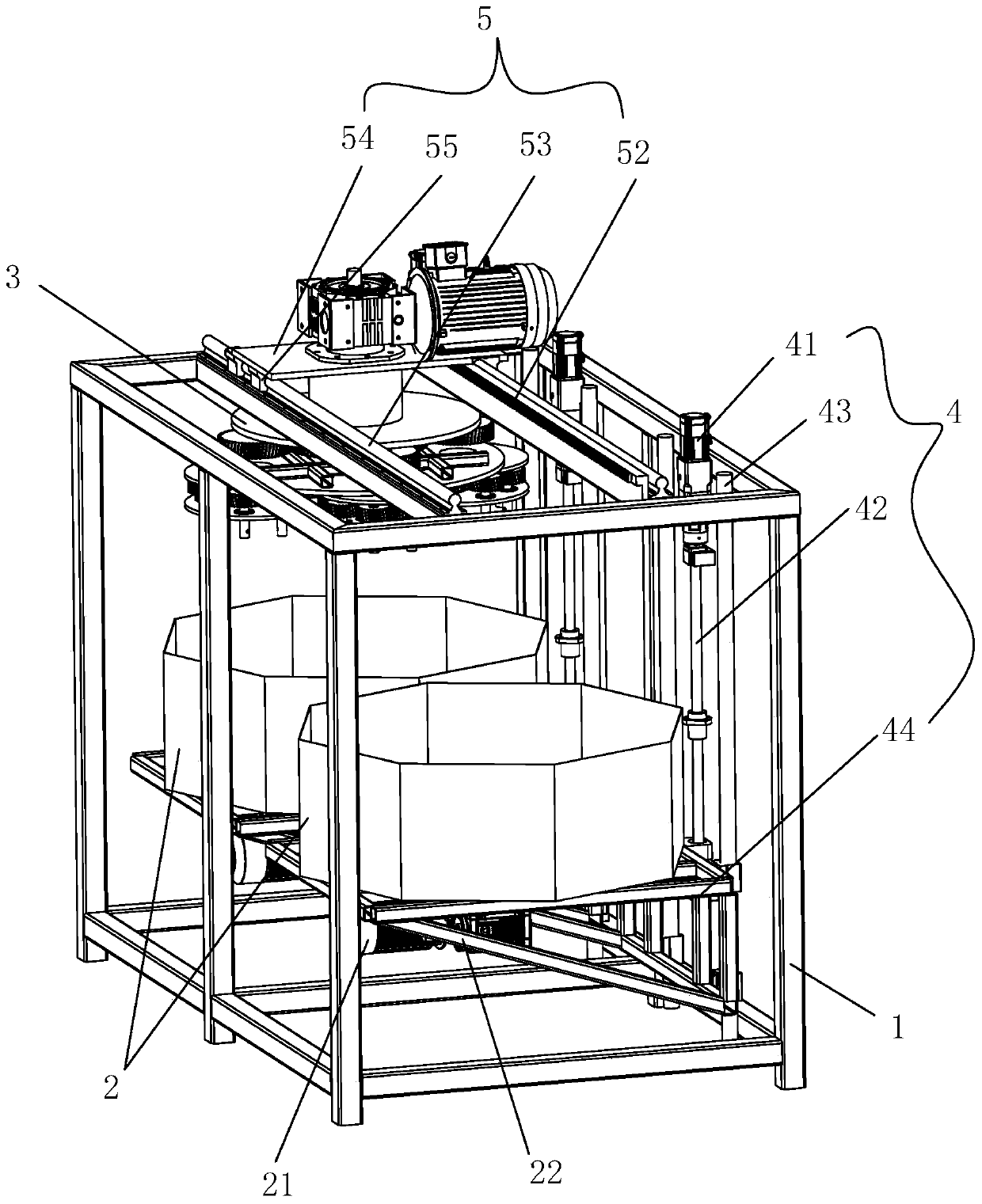

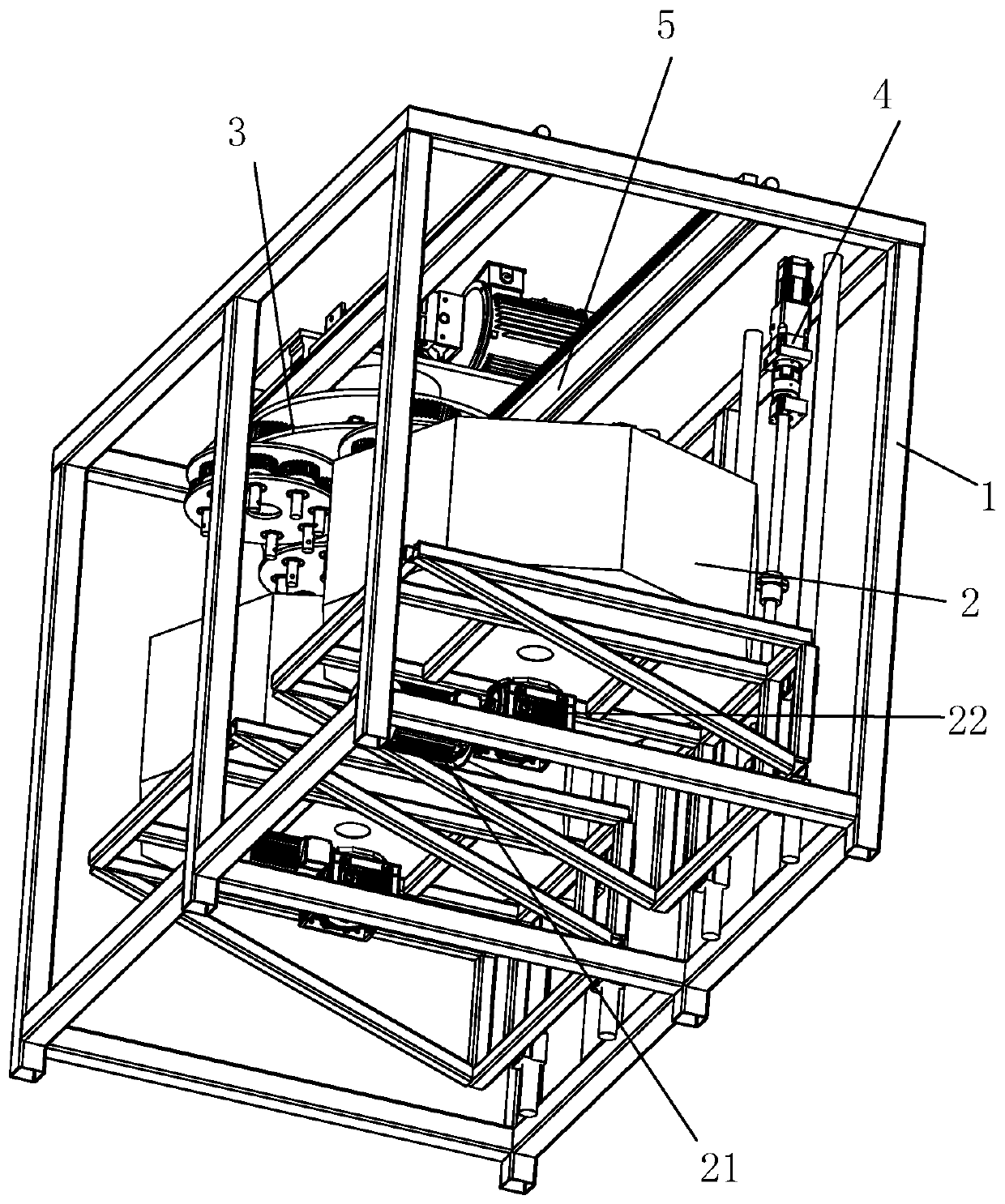

[0040] see Figure 1 to Figure 7As shown, the vertical polishing and grinding machine disclosed by the present invention includes a frame 1 , two abrasive drums 2 and a set of rotating mechanisms 3 . Two sets of lifting devices 4 are installed side by side on the side of the frame 1, and a set of translation device 5 is installed on the top surface of the frame 1. The two abrasive cylinders 2 are rotatably installed on two sets of lifting devices 4, and the lifting device 4 drives the abrasive cylinders 2 to move up and down. The two abrasive cylinders 2 are respectively filled with coarse and fine materials, which can be Grinding and fine grinding, realizing double-level processing, saving time for changing abrasives and workpieces, and further improving efficiency. The openings of the two abrasive cylinders 2 are upward, so that the abrasive cylinders 2 are vertical. An abrasive motor 21 and an abrasive reducer 22 are respectively installed at the bottom of each abrasive c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com