A controllable progressive loading and clamping device and method for laser joining of thermoplastic composite materials and light alloys

A composite material and lightweight alloy technology, applied in the field of controllable progressive loading and clamping equipment, can solve the problems of complex and cumbersome process, low efficiency, long time consumption, etc., achieve process parameter optimization, high degree of flexibility, and promote flow and diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

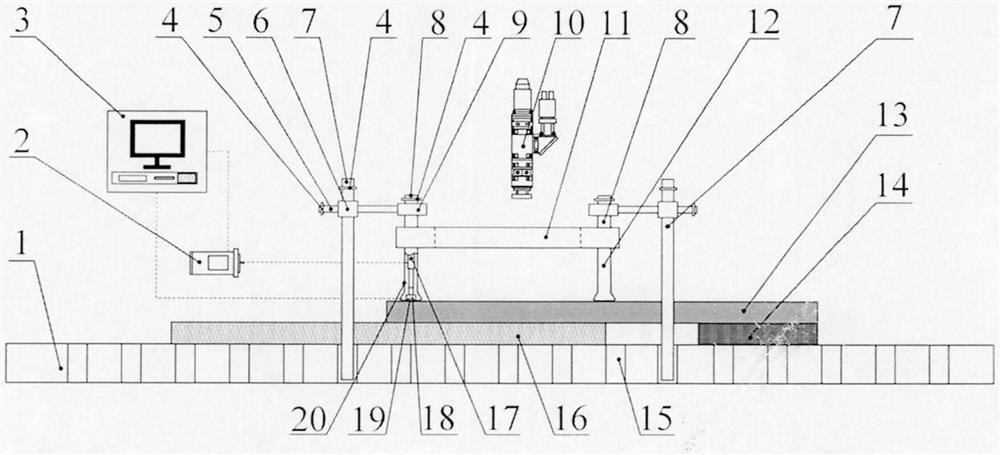

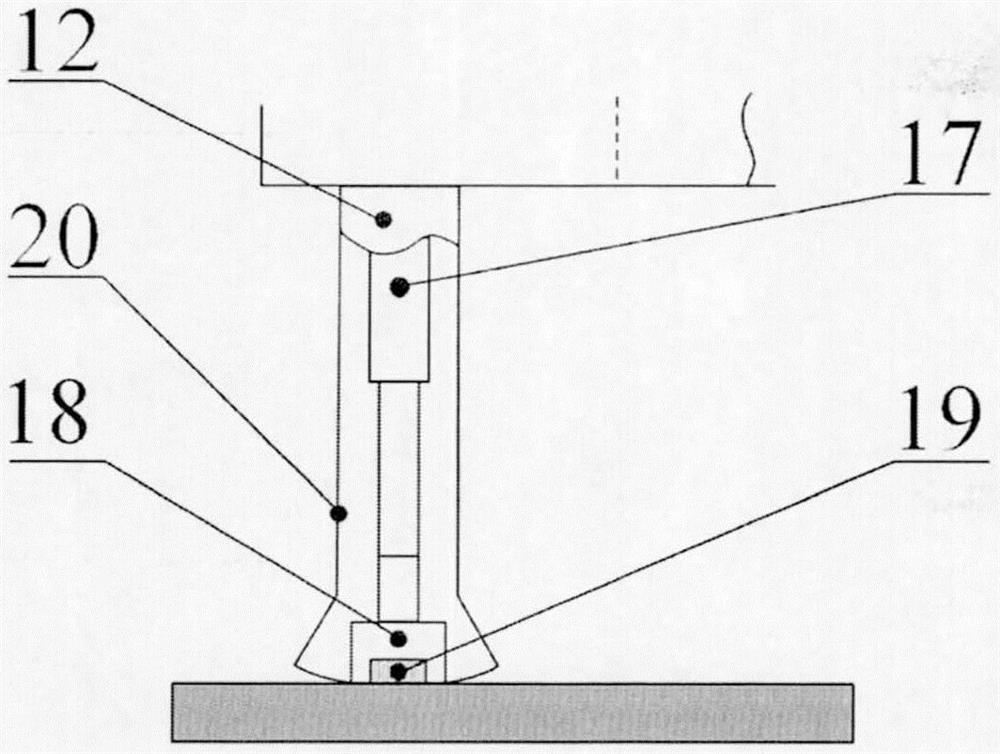

[0035] Such as figure 1 shown. The invention discloses a controllable progressive loading and clamping device for laser connection of thermoplastic composite materials and light alloys, including a working platform, a fixing system, a monitoring and feedback system, a control center, a pressure applying system and a return frame.

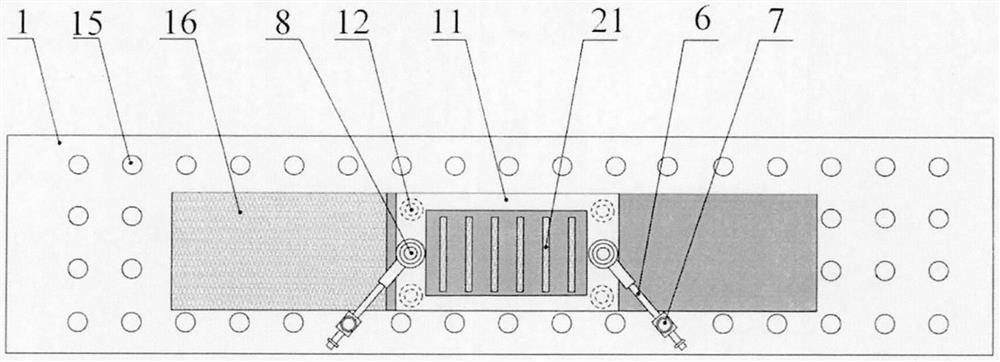

[0036] The working platform 1 is used for thermoplastic composite materials, and is characterized in that there are a plurality of positioning holes 15 for fixing the clamping equipment on the working platform 1;

[0037] The fixing system is used to fix the clamping equipment and connecting parts, including the main fixed arm 7, the auxiliary fixed arm 8, the rotating rod 5, the limit plate 4, the main card holder 6 and the auxiliary card holder 9. The main fixed arm 7 and the auxiliary fixed arm 9 are connected to the bracket through the rotating rod 5, the bottom of the main fixed arm 7 is inserted into the positioning hole, and the auxiliary fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com