Differential chain production assembly line for double speed converting regulation of separation distance chain wheel for lamp transportation

A production line and differential chain technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of large loss and offset of rods, large rough surface of sponge pads, sudden stop and repair of chain belts, etc. Achieve the effect of improving sprocket maintenance and improving overall tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

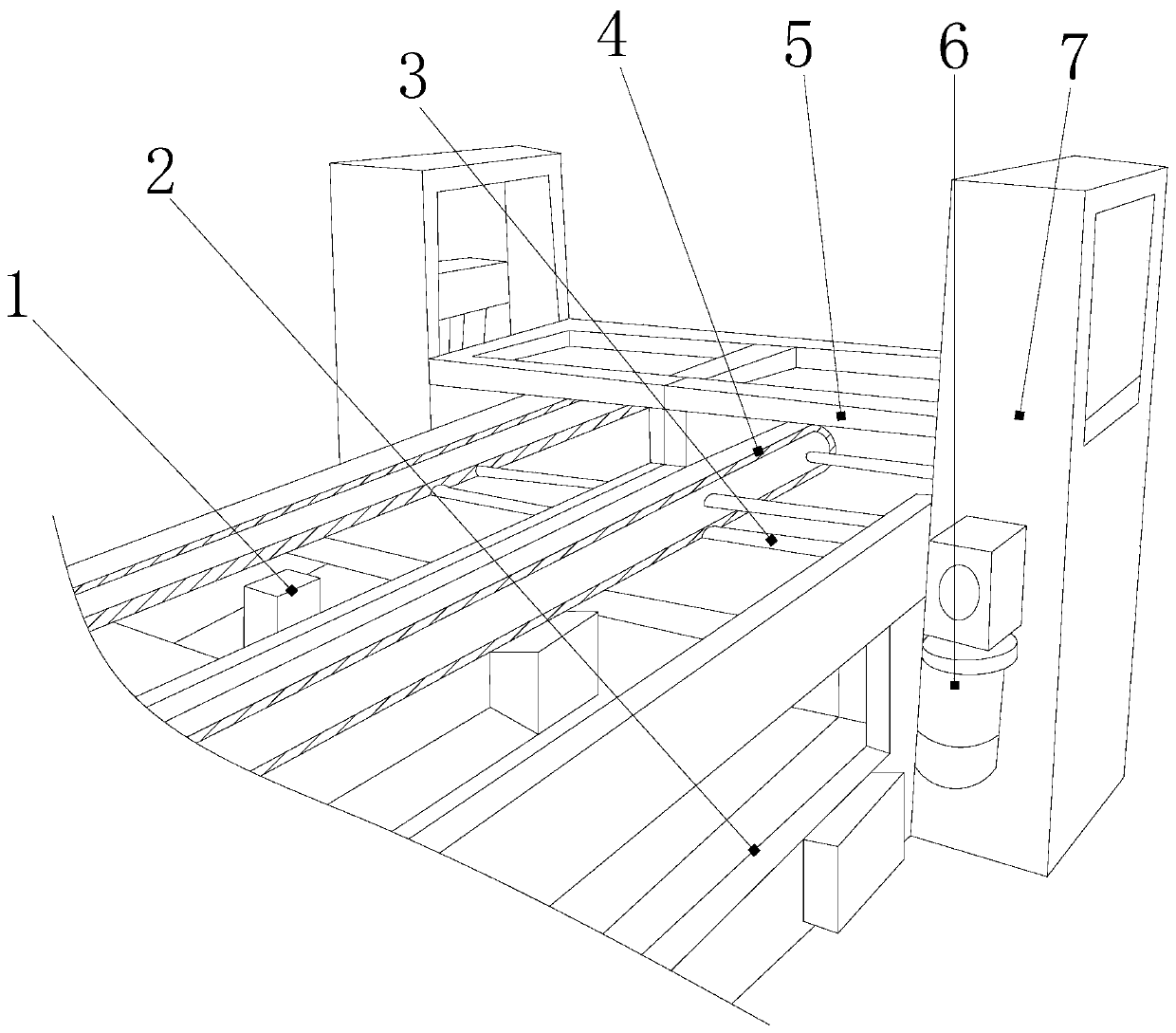

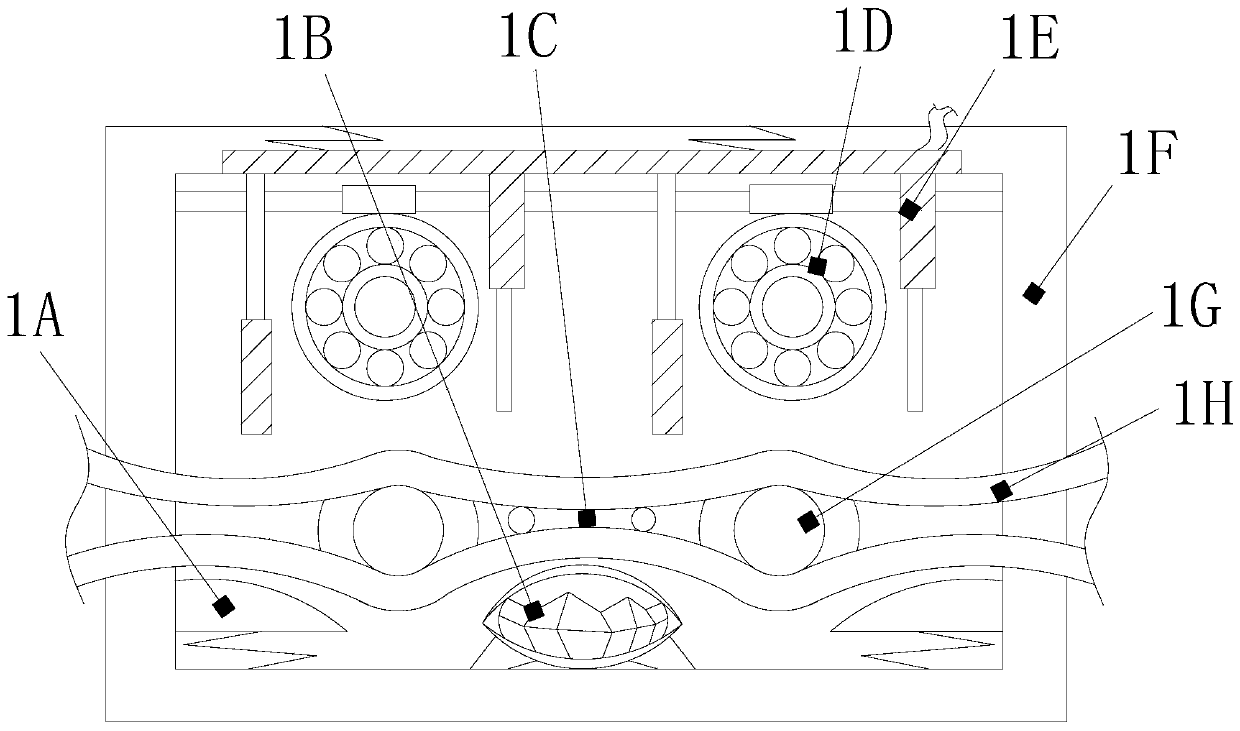

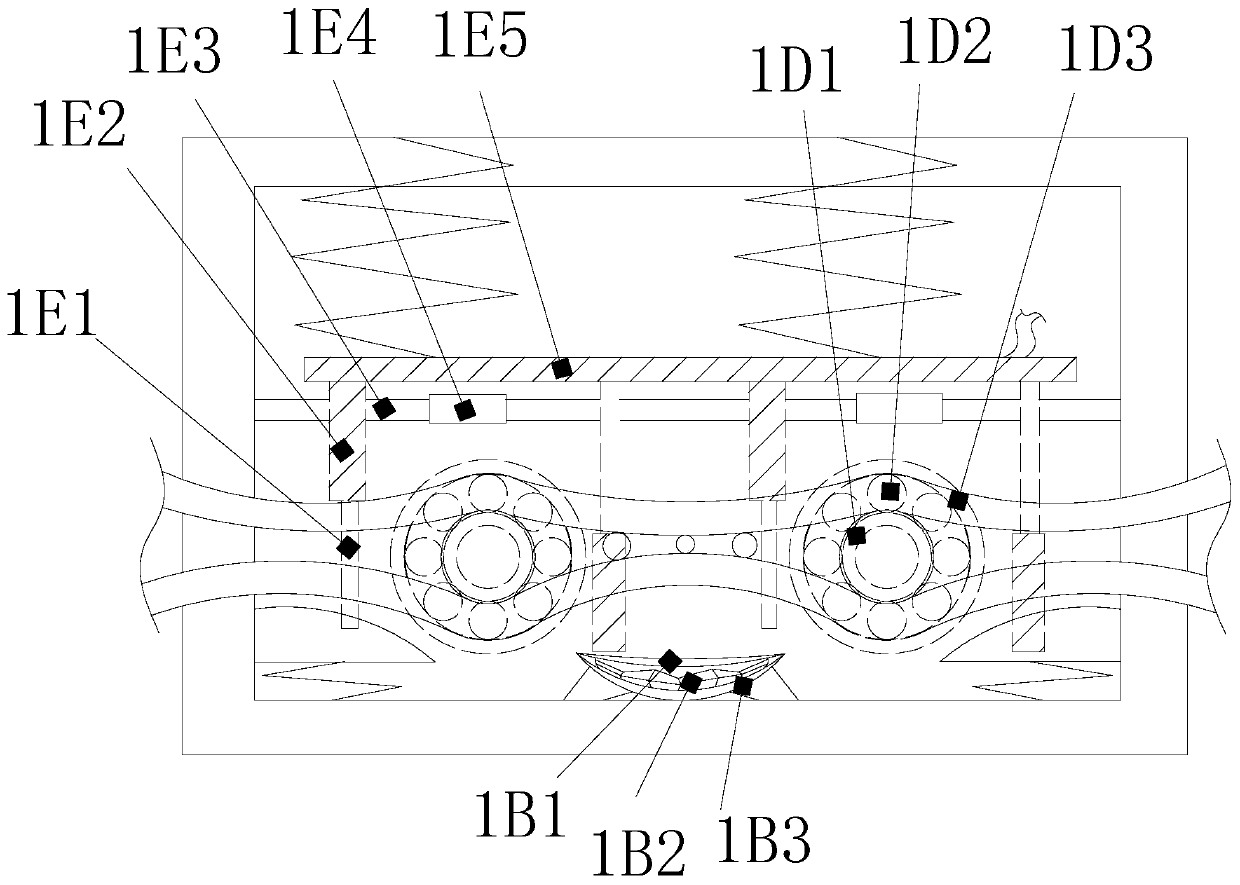

[0032] see Figure 1-Figure 7 , the present invention provides a differential chain production line controlled by double-speed sprocket rotation for the distance between lamps and lanterns. Bracket 5, shaft motor 6, baffle frame 7, the sprocket deviation correction chassis 1 and the differential chain belt 4 are fastened together and are on the same vertical plane, and the differential chain belt 4 is installed on the bottom On the top of the frame board seat 2, the bottom frame board seat 2 is welded together with the baffle frame 7, and the baffle frame 7 is provided with two and respectively nested on the left and right sides of the workbench bracket 5 , the shaft motor 6 is mechanically connected with the baffle shell frame 7 and is on the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com