Silicate polyurethane composite reinforcing material for coal mines and preparation method of silicate polyurethane composite reinforcing material

A reinforcement material and silicate technology, which is applied in the field of silicate polyurethane composite reinforcement materials for coal mines and its preparation, can solve problems such as poor antistatic performance, high cost, and insufficient flame retardancy, and achieve improved stability and fluidity. Good performance, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The described silicate polyurethane composite reinforcement material for coal mines is made of component A and component B, wherein:

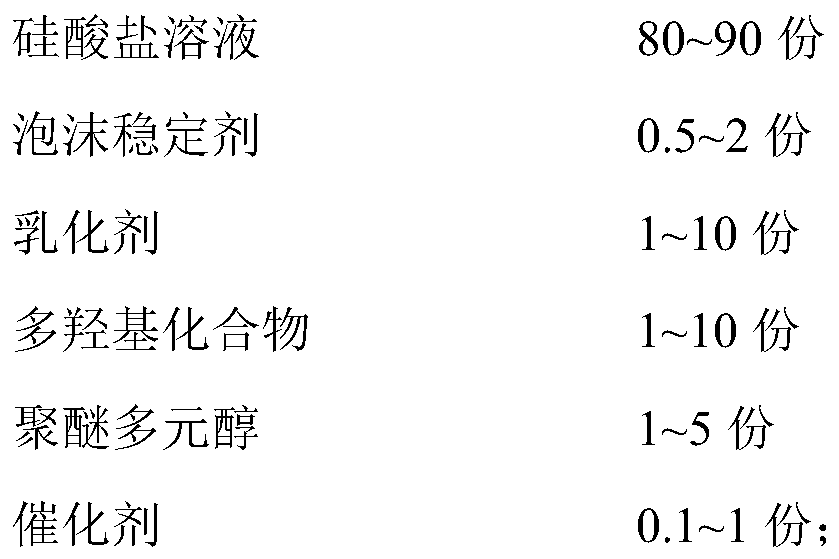

[0031] Component A is, in parts by weight:

[0032]

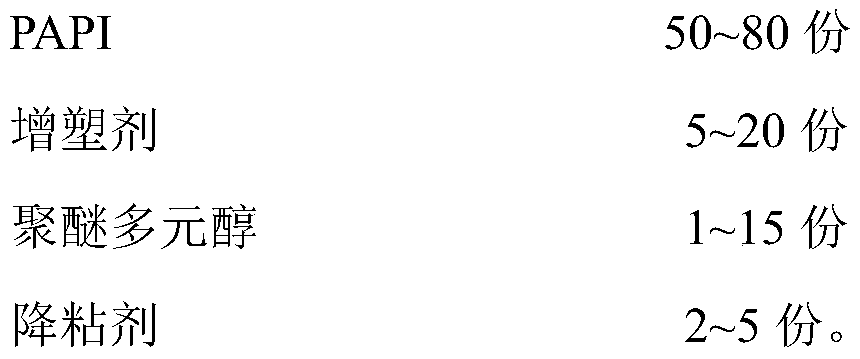

[0033] Component B is, in parts by weight:

[0034]

[0035] The sodium silicate solution has a modulus of 2.4 and a Baume degree of 48°; the polyether polyol uses glycerol as an initiator, a polyether polyol with a functionality of 3 and a hydroxyl value of 450 mgKOH / g.

[0036] The preparation method comprises the following steps:

[0037] (1) Mix sodium silicate solution, AK-8805, glycerin, glucose, polyether polyol and dimethylaminoethoxyethanol in proportion to obtain component A;

[0038] (2) After PAPI, dioctyl phthalate, polyether polyol and propylene carbonate are mixed uniformly in proportion, component B is obtained;

[0039] When using, grout according to the volume ratio of component A and component B is 1:1.

Embodiment 2

[0041] The described silicate polyurethane composite reinforcement material for coal mines is made of component A and component B, wherein:

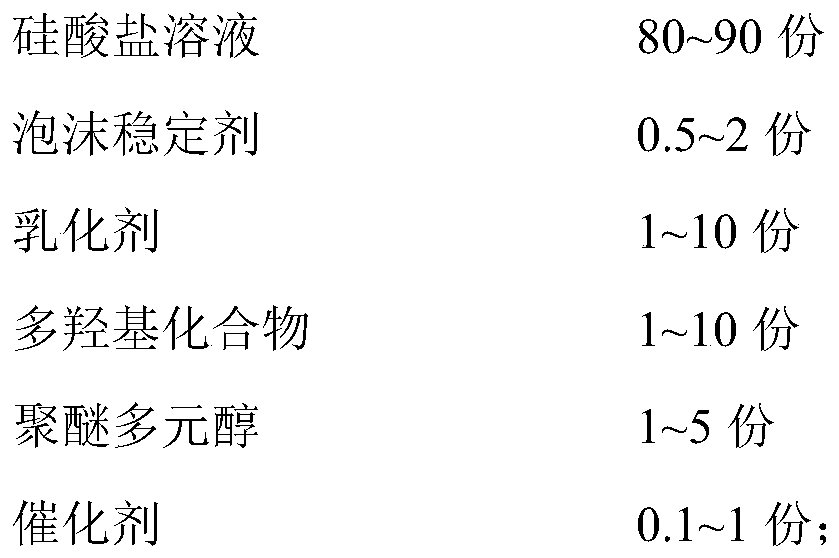

[0042] Component A is, in parts by weight:

[0043]

[0044] Component B is, in parts by weight:

[0045]

[0046] The sodium silicate solution has a modulus of 2.6 and a Baume degree of 45°; the polyether polyol uses glycerol as an initiator, has a functionality of 3 and a hydroxyl value of 400.

[0047] The preparation method comprises the following steps:

[0048] (1) Mix sodium silicate solution, AK-8805, glycerin, ethylene glycol, maltose, polyether polyol and dimethylaminoethoxyethanol in proportion to obtain component A;

[0049] (2) After PAPI, dioctyl phthalate, polyether polyol and propylene carbonate are mixed uniformly in proportion, component B is obtained;

[0050] When using, grout according to the volume ratio of component A and component B is 1:1.

Embodiment 3

[0052] The described silicate polyurethane composite reinforcement material for coal mines is made of component A and component B, wherein:

[0053] Component A is, in parts by weight:

[0054]

[0055] Component B is, in parts by weight:

[0056]

[0057] The potassium silicate solution has a modulus of 2.8 and a Baume degree of 44°; the polyether polyol uses ethylene glycol as an initiator, a polyether polyol with a functionality of 2 and a hydroxyl value of 100.

[0058] The preparation method comprises the following steps:

[0059] (1) Mix potassium silicate solution, AK-158, glycerol, glucose, polyether polyol and dimethylaminoethoxyethanol in proportion to obtain component A;

[0060] (2) After PAPI, dioctyl phthalate, polyether polyol and propylene carbonate are mixed uniformly in proportion, component B is obtained;

[0061] When using, grout according to the volume ratio of component A and component B is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com