Oil discharge silica gel and preparation method thereof

A technology of silica gel and raw rubber, applied in the direction of adhesives, natural rubber adhesives, adhesive types, etc., can solve the problem of insignificant effect, and achieve the effect of superior lubricating performance, good oil performance, and not easy to be oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A raw material for preparing oil-releasing silica gel includes: extra-high hexenyl content raw rubber, raw rubber, silicone oil, hydrogen-containing silicone oil, mold release agent, blue pigment, carbon black and phenyl silicone oil.

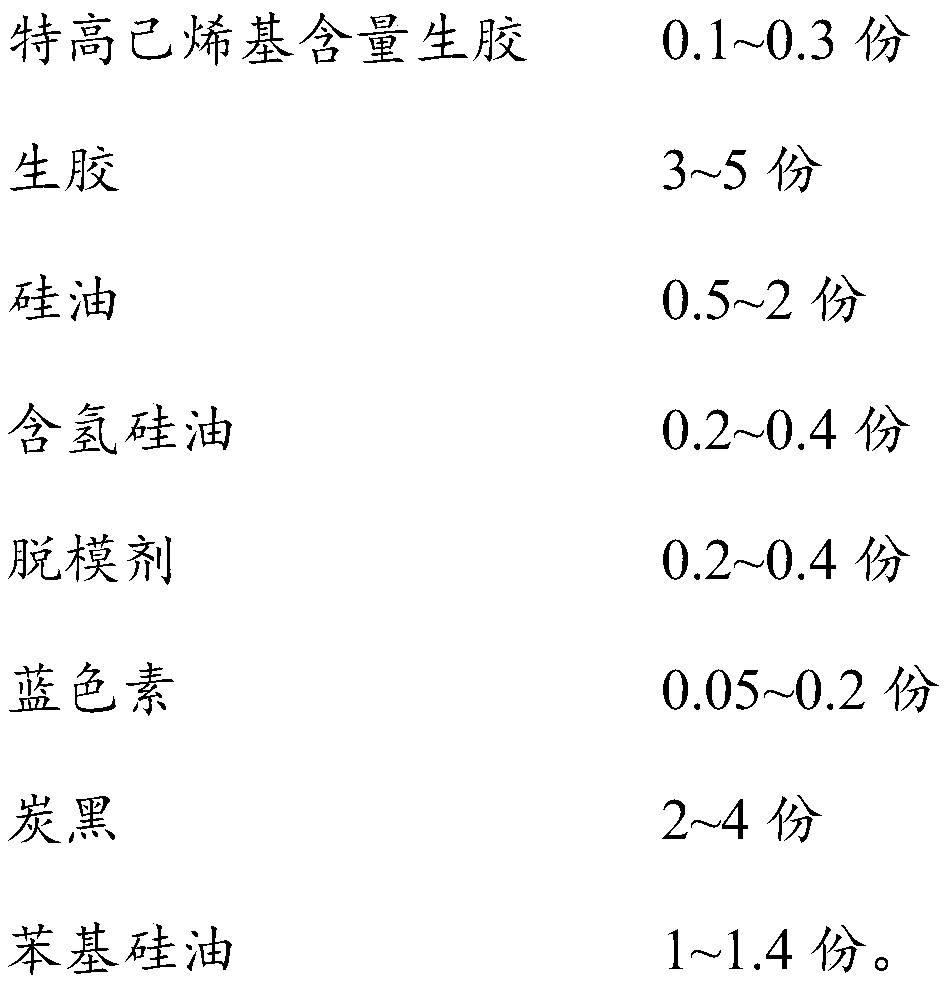

[0022] Wherein, the oil-releasing silica gel of the present invention includes the following components in parts by weight:

[0023]

[0024] Among them, the relative molecular weight of the ultra-high hexenyl content raw rubber is 55×10 4 , the vinyl content of the ultra-high hexenyl content raw rubber is 3%.

[0025] Wherein, the raw rubber is selected from smoked sheet rubber.

[0026] Among them, the viscosity of silicone oil is 3200cP.

[0027] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 1.8wt%.

[0028] Wherein, the release agent is selected from silicone compounds.

[0029] Wherein, the viscosity of the phenyl silicone oil at 25°C is 45cs, the refractive index ND of the phenyl silicone oil is 1....

Embodiment 2

[0035] A raw material for preparing oil-releasing silica gel includes: extra-high hexenyl content raw rubber, raw rubber, silicone oil, hydrogen-containing silicone oil, mold release agent, blue pigment, carbon black and phenyl silicone oil.

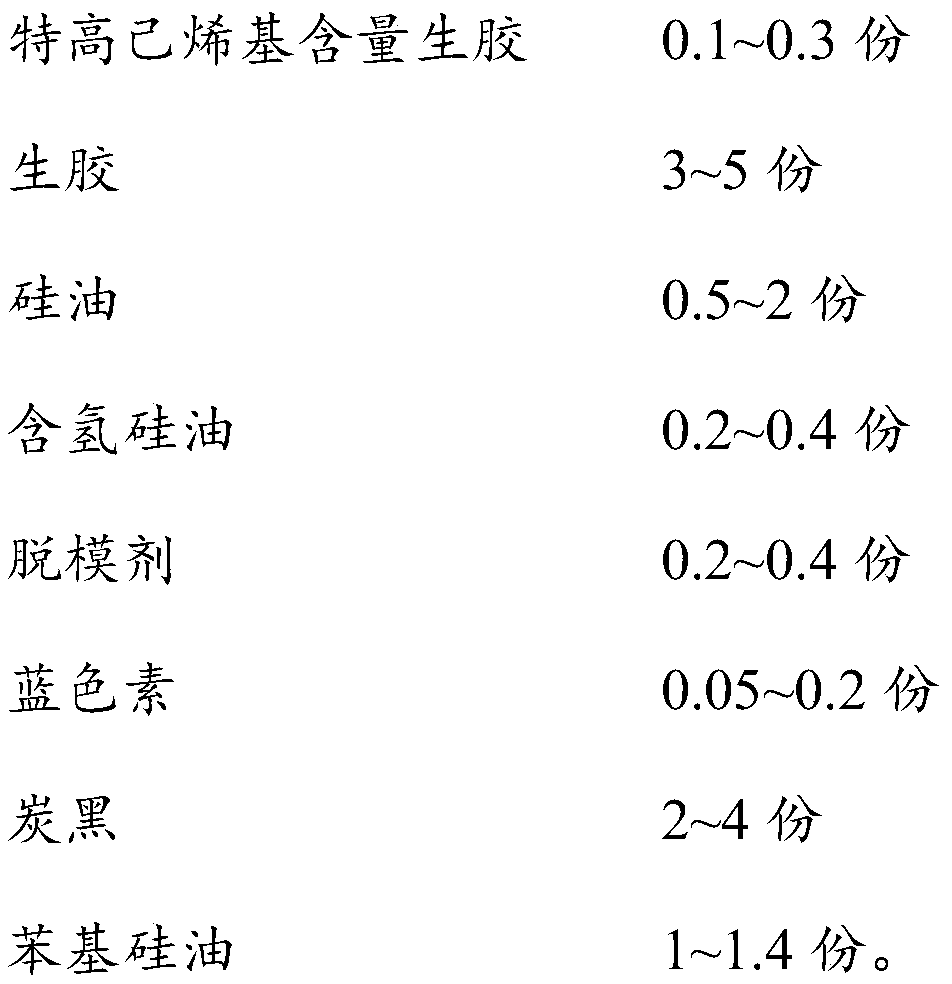

[0036] Wherein, the oil-releasing silica gel of the present invention includes the following components in parts by weight:

[0037]

[0038]

[0039] Among them, the relative molecular weight of the ultra-high hexenyl content raw rubber is 40×10 4 , the vinyl content of the ultra-high hexenyl content raw rubber is 2.5%.

[0040] Wherein, raw rubber is selected from standard rubber.

[0041] Wherein, the viscosity of silicone oil is 1500cP.

[0042] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 1.6wt%.

[0043] Wherein, the release agent is selected from silicone grease.

[0044] Wherein, the viscosity of the phenyl silicone oil at 25°C is 75cs, the refractive index ND of the phenyl silicone oil is 1....

Embodiment 3

[0050] A raw material for preparing oil-releasing silica gel includes: extra-high hexenyl content raw rubber, raw rubber, silicone oil, hydrogen-containing silicone oil, mold release agent, blue pigment, carbon black and phenyl silicone oil.

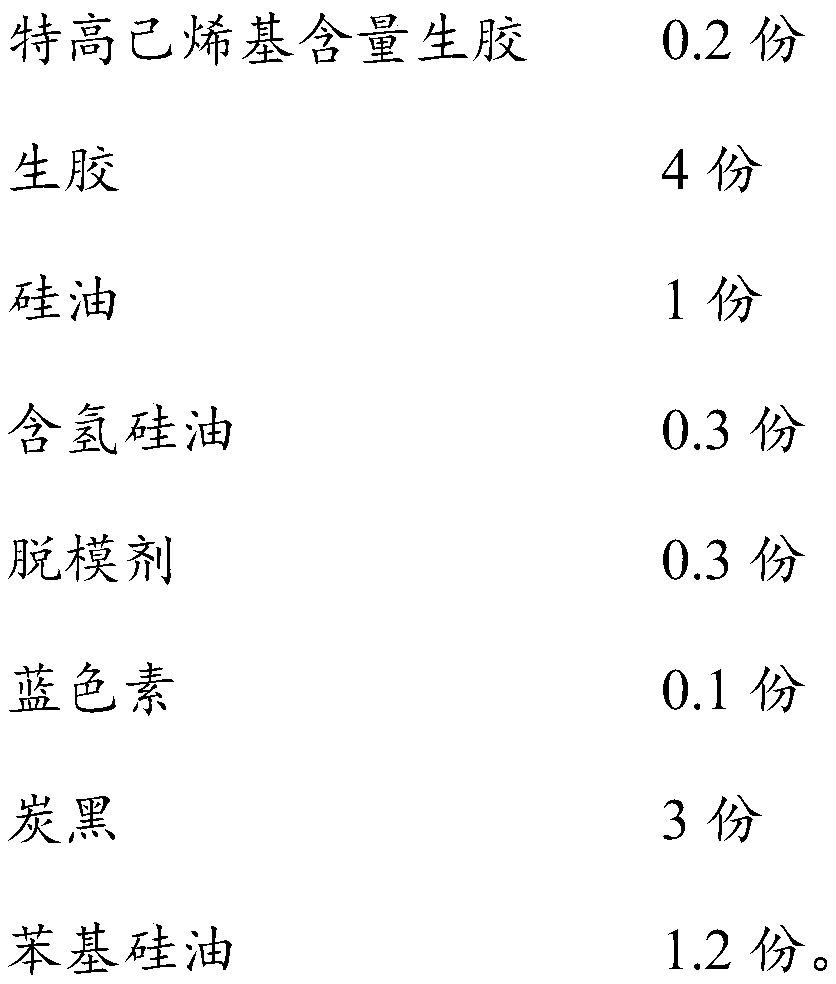

[0051] Wherein, the oil-releasing silica gel of the present invention includes the following components in parts by weight:

[0052]

[0053] Among them, the relative molecular weight of the ultra-high hexenyl content raw rubber is 50×10 4 , the vinyl content of the ultra-high hexenyl content raw rubber is 3.5%.

[0054] Wherein, the raw rubber is selected from styrene-butadiene rubber.

[0055] Wherein, the viscosity of silicone oil is 1500cP.

[0056] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 2wt%.

[0057] Wherein, the release agent is selected from silicone resin.

[0058] Wherein, the viscosity of the phenyl silicone oil at 25°C is 75cs, the refractive index ND of the phenyl silicone oil is 1.49...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com