A kind of high-strength and high-fracture-toughness aluminum alloy bar and its preparation method

A high-fracture, aluminum alloy technology, which is applied in the field of scandium-containing aluminum-zinc-magnesium alloy rods and its preparation, can solve the problems of weakening the anti-crack propagation effect of Sc elements and reducing fracture toughness, so as to improve the alloy's resistance to crack initiation and The effect of expansion ability, high fracture toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The constituent elements of the bar are: Mg 5wt%, Zn 2wt%, Sc 0.4wt%, Al 92.6wt%, Fe, Si and other impurity elements content ≤ 0.1wt%.

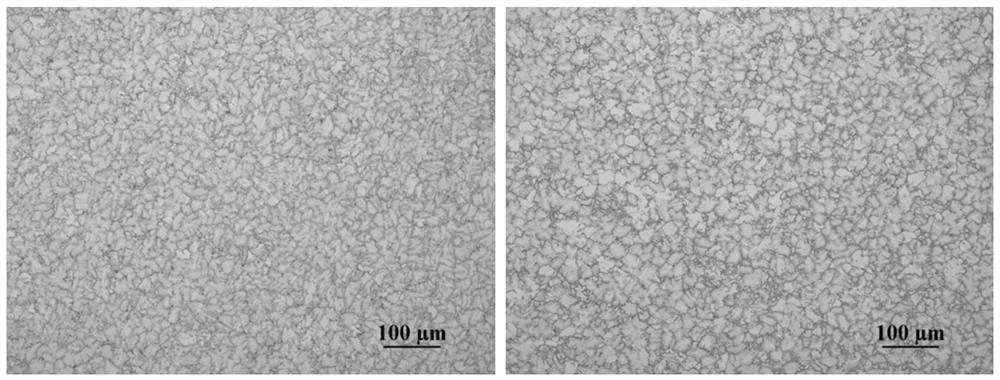

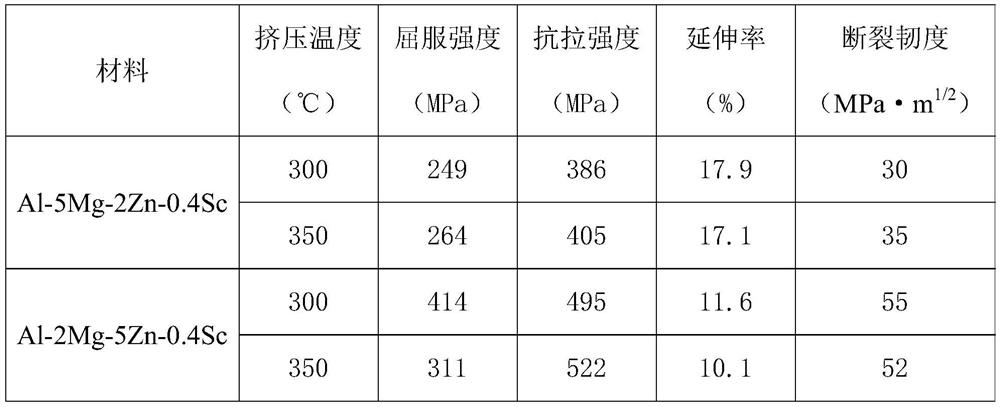

[0027] According to the ratio, aluminum ingots with a purity of ≥99.9% are melted in a graphite crucible of an intermediate frequency induction melting furnace. For zinc ingots and Al-2% Sc master alloys, heat up to 730°C for full stirring after the alloy is melted, refine and degas at 720°C after standing for 20 minutes, let stand for 20 minutes after removing slag from the melt, and quickly melt the molten metal at 700°C Pouring into aluminum alloy ingots; brightening the surface of the ingots, preheating the ingots and performing hot extrusion at an extrusion ratio of 25 at extrusion temperatures of 300 and 350°C to obtain rods after post-treatment. Its mechanical properties at room temperature are shown in Table 1. It can be seen that the yield strength of the bar is 249-264MPa, the tensile strength is 386-405MPa, the elongation i...

Embodiment 2

[0029] The constituent elements of the rod are: Mg 2wt%, Zn 5wt%, Sc 0.4wt%, Al 92.6wt%, Fe, Si and other impurity elements content ≤ 0.1wt%.

[0030]According to the ratio, aluminum ingots with a purity of ≥99.9% are melted in a graphite crucible of an intermediate frequency induction melting furnace. For zinc ingots and Al-2% Sc master alloys, heat up to 730°C for full stirring after the alloy is melted, refine and degas at 720°C after standing for 20 minutes, let stand for 20 minutes after removing slag from the melt, and quickly melt the molten metal at 700°C Pouring into aluminum alloy ingots; brightening the surface of the ingots, preheating the ingots and performing hot extrusion at an extrusion ratio of 25 at extrusion temperatures of 300 and 350°C to obtain rods after post-treatment. Its mechanical properties at room temperature are shown in Table 1. It can be seen that the yield strength of the bar is 311-414MPa, the tensile strength is 495-522MPa, the elongation is...

Embodiment 3

[0036] The constituent elements of the bar are: Mg 3wt%, Zn 1wt%, Sc 0.3wt%, Fe, Si and other impurity elements content ≤ 0.1wt%, the balance is aluminum Al.

[0037] According to the ratio, the aluminum ingot with a purity ≥ 99.9% is melted in a graphite crucible of an intermediate frequency induction melting furnace. After it is completely melted, the temperature of the molten aluminum is 660°C-670°C. For zinc ingots and Al-2% Sc master alloys, heat up to 740°C for full stirring after the alloy is melted, refine and degas at 730°C after standing for 20 minutes, let stand for 20 minutes after removing slag from the melt, and quickly melt the molten metal at 710°C Pouring into aluminum alloy ingots; brighten the surface of the ingots, preheat the ingots and carry out hot extrusion at an extrusion ratio of 50, the extrusion temperature is 300, 350 ° C, and obtain rods after post-treatment. The yield strength of the bar is 250-264MPa, the tensile strength is 386-405MPa, the elon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com