A rapid underground excavation construction method for long-span shallow-buried tunnels

A technology for shallow buried tunnels and construction methods, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of difficult construction of large-span tunnels, poor geological conditions, slow construction progress, etc. Avoid the effect of destabilizing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

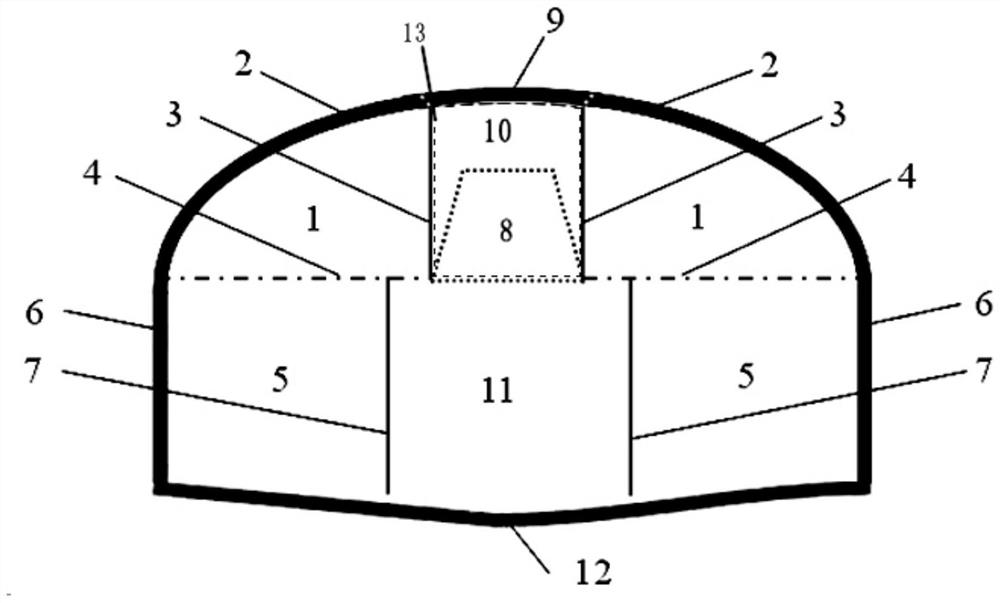

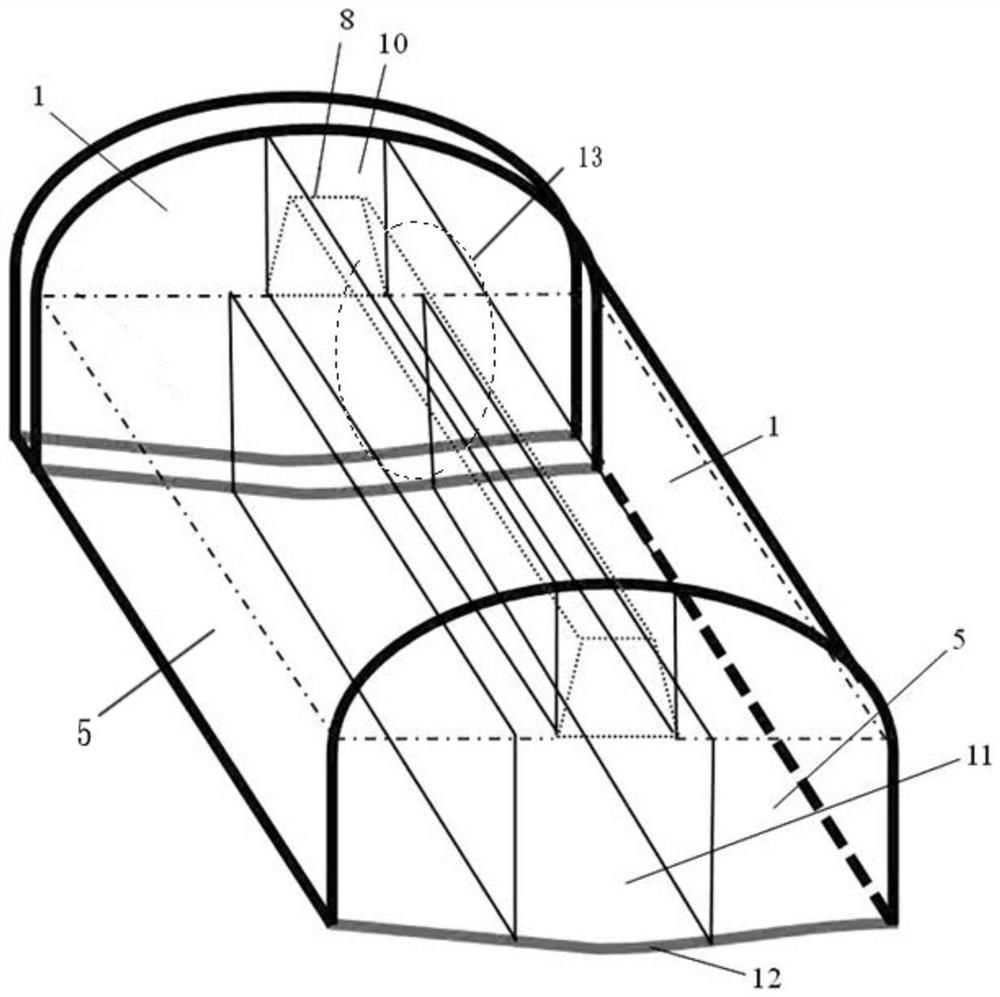

[0023] Such as Figure 1-2 As shown, a fast underground excavation construction method for a large-span shallow buried tunnel includes the following steps:

[0024] Step 1: Excavate synchronous and symmetrical pilot pits on both sides of the upper part of the tunnel along the longitudinal direction of the tunnel to form horizontal left and right upper sections, and reserve the upper core soil column in the middle, whose width is 1 / 5 of the span of the tunnel section;

[0025] Step 2: Support the excavated left and right upper sections of the upper part of the tunnel, and permanently support the outer walls of the arch top, which can be supported in the form of shotcrete and / or bolts plus shotcrete, and steel frames , can be used as a primary lining; on both sides of the reserved upper core soil column, two vertical upper middle partitions and transverse cross bracing temporary supports are built, and the two vertical upper middle partitions are respectively located at 2 / 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com