Polyolefin plastic-coated optical fiber bundling process

A polyolefin and optical fiber bundle technology, applied in the field of optical cable manufacturing, can solve the problems of small number of cores, unable to meet the requirements of users for large-scale and large-capacity building wiring, etc., and achieve the effect of light weight, simple structure and high fiber capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a polyolefin sheathed optical fiber bundling process, and the process flow is as follows:

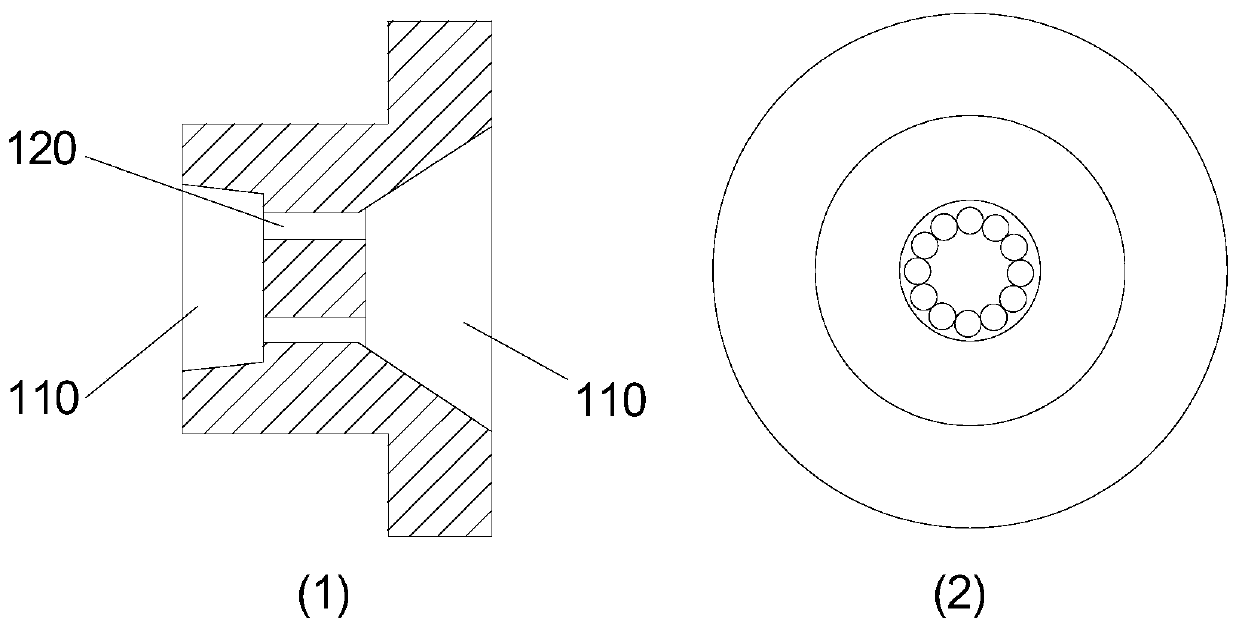

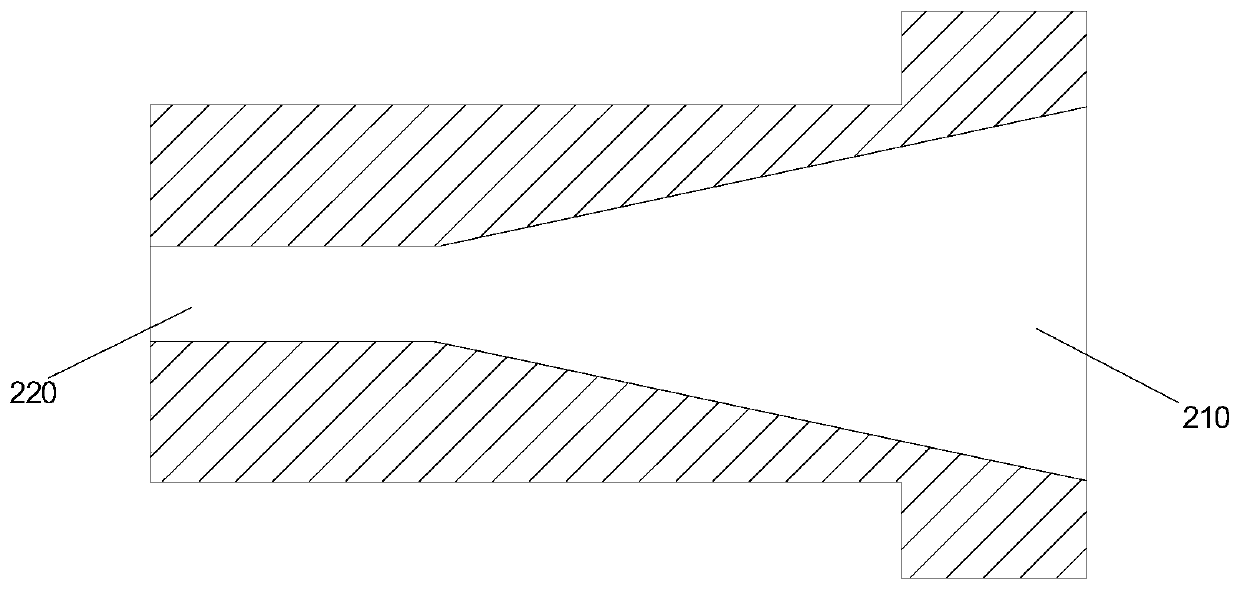

[0039] 12 channels of G.657A2 colored optical fiber are released by the active pay-off frame, the pay-off tension is 80g / channel, and after passing through the fiber splitting mold, it enters the stranding table, and the stranding table performs reverse stranding, and the stranding pitch is 600mm. The stranding angle is 180°, and the stranding direction is forward and reverse. After the stranded optical fiber bundle is positioned by the optical fiber positioning mold, it enters the powder coating box for coating, and then enters the extruder head for extrusion. The extruded material is polyolefin material, and the extrusion temperature is 140-175°C. After being covered with plastic, it enters the vacuum sizing device, and the inner diameter of the sizing mold is 1.30mm. After sizing, the plastic-coated optical fiber first enters the first hot water trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com