Solar photovoltaic module and preparation method thereof

A solar photovoltaic and component technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of reducing the shading area of the grid line on the front of the cell, reducing the current transmission resistance of the cell, etc., to reduce the area, reduce the production time, The effect of increasing the power of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

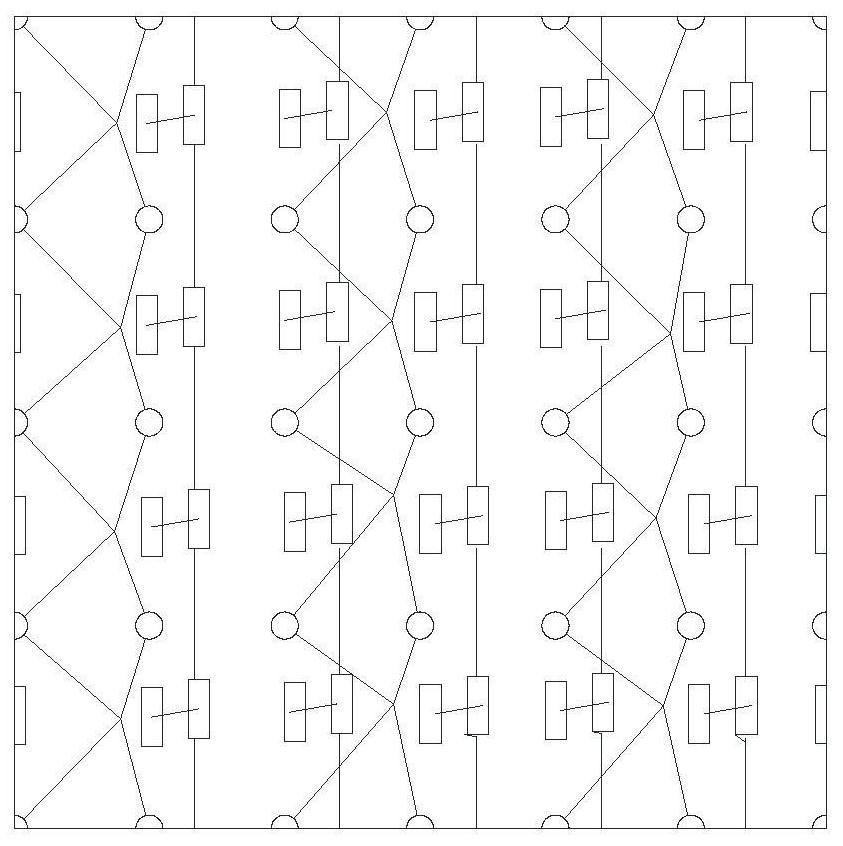

[0046] Such as Figure 4 As shown, the photovoltaic module 7 of this embodiment includes a front plate, a front encapsulation layer, a battery layer and a composite bottom plate 8 arranged in sequence from top to bottom, and the battery layer is formed by arranging a plurality of battery sheets 1 .

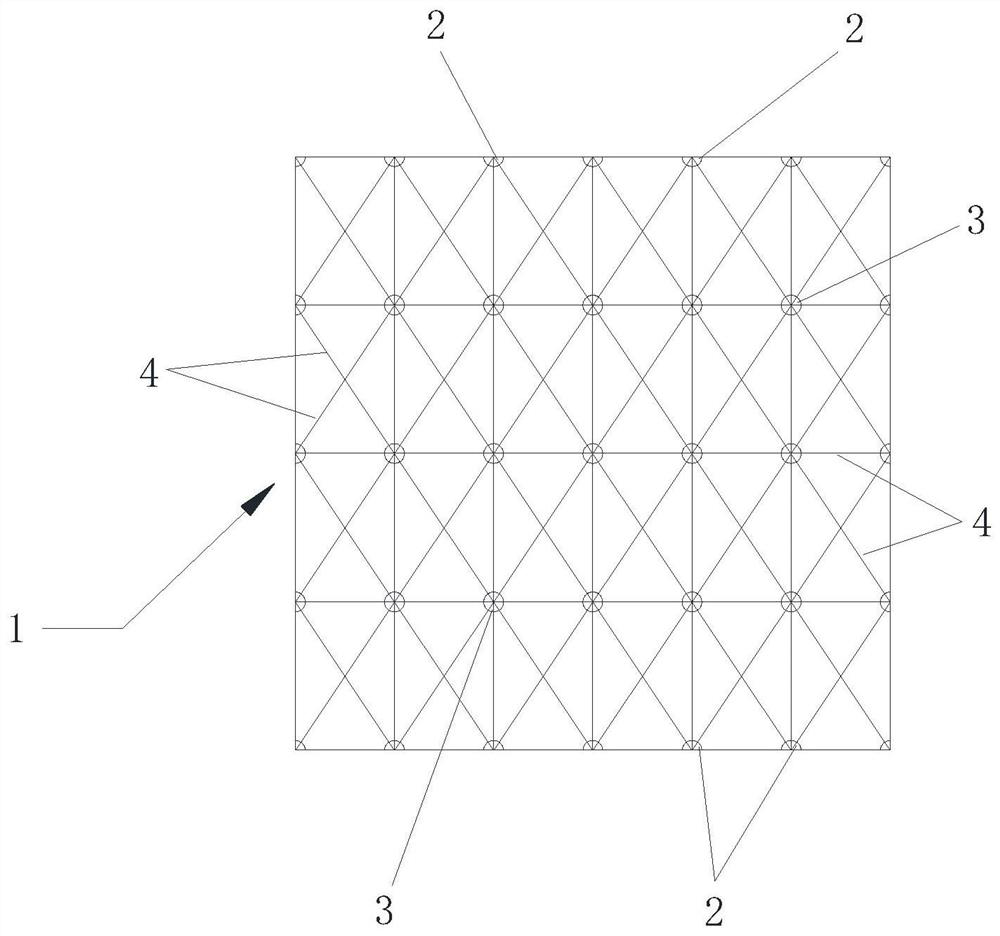

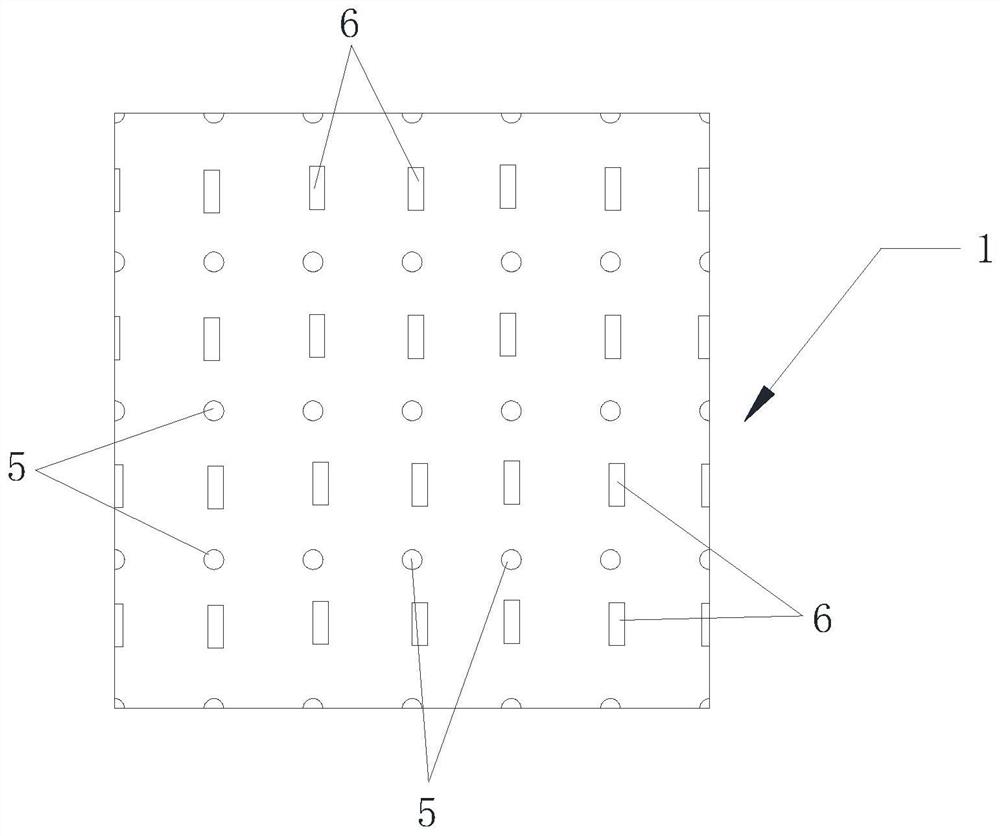

[0047] The solar cell sheet 1 of the present embodiment, as Figure 1-2 As shown, there is a back electrode 6 on the back, but there is no busbar on the front, and there are fine grid lines 4 on the front, and the fine grid lines 4 are densely meshed, and the distance between adjacent fine grid lines 4 is 1-2mm. The edge of the solar cell 1 is provided with a through groove 2 passing through its thickness direction and / or the inside of the solar cell 1 is provided with a through hole 3 passing through its thickness direction, and the through groove 2 and the through hole 3 are coated with an insulating material 9 .

[0048] Through-grooves 2 or through-holes 3 are regularly open...

Embodiment 2

[0058] This embodiment provides a method for preparing the solar photovoltaic module 7 described in Embodiment 1, which specifically includes the following steps:

[0059] 1) Select the battery sheet 1 with fine grid lines 4 and back electrodes 6 prepared, and open through grooves 2 and / or through holes 3 through its thickness direction.

[0060] The manufacturing method of the through groove 2 or the through hole 3 provided in this embodiment is to use laser and water to alternately cut the battery sheet 1 so that the battery sheet 1 is cut along the cutting path to form the through groove 2 or the through hole 3 . Cutting is performed with a laser and it is ensured that the battery sheet 1 is not disconnected after the laser cutting.

[0061] The parameters of the laser cutting in this embodiment are as follows: the laser power is 20W, the laser frequency is 600kHz, the laser running speed, that is, the moving speed of the laser is 22000cm / min, and the laser cutting time of ...

Embodiment 3

[0073] Such as Figure 5-7 As shown, the photovoltaic module 7 and the solar battery sheet 1 in this embodiment are basically similar to the first embodiment, the difference is that in this embodiment, the solar battery sheet 1 is not opened at the four corners and two of the sides. through the groove 2, so when the photovoltaic module 7 is prepared, the battery sheets 1 can only be connected to each other vertically to form a battery string, but cannot be connected horizontally.

[0074] The manufacturing method of the through-groove 2 and the through-hole 3 in this embodiment is basically similar to that of Embodiment 1, the difference is that in this embodiment, there are 12 busbars of the battery sheet 1, and the laser-cut The parameters are as follows: the laser power is 15W, the laser frequency is 500kHz, the laser running speed, that is, the moving speed of the laser is 18000cm / min, and the laser cutting time of the single cell 1 is 2s. The parameters of water cutting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com