Full polarization-maintaining 9-shaped cavity mode-locked laser with high repetition frequency

A high repetition rate, mode-locked laser technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of inability to achieve full polarization maintenance and poor environmental stability, so as to improve self-starting performance and repeatability Good frequency and environmental stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

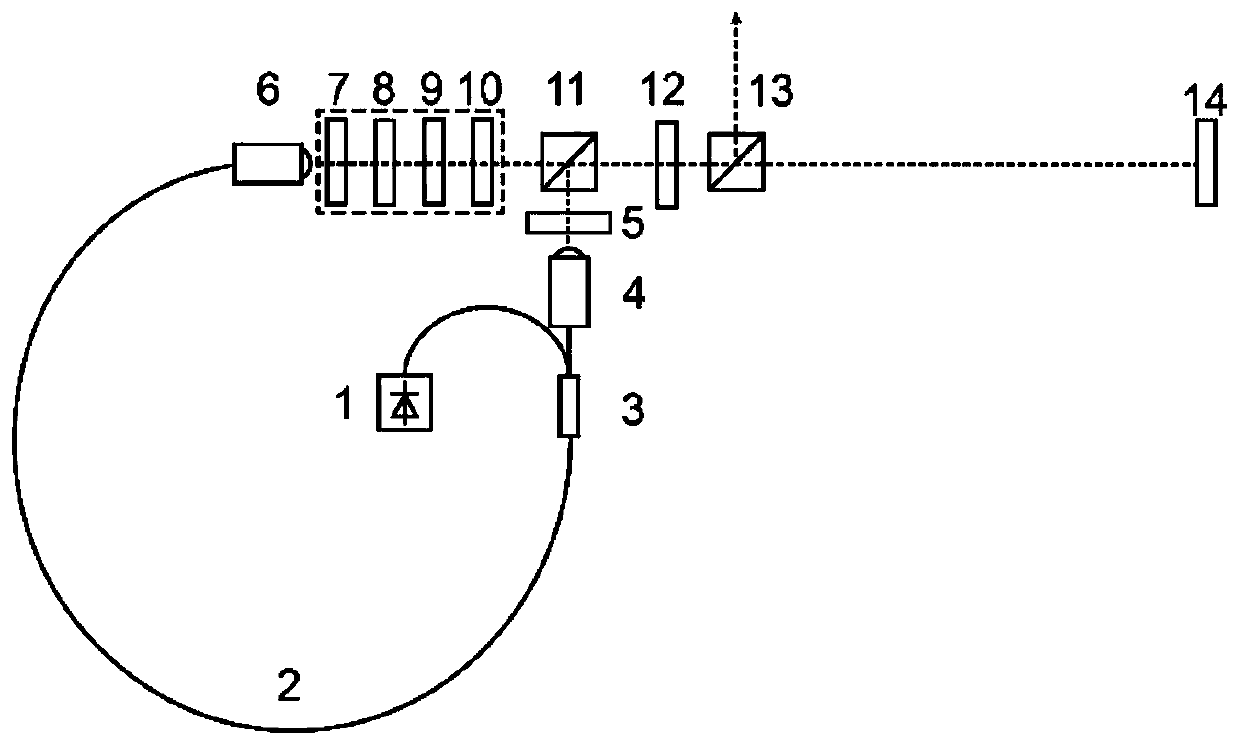

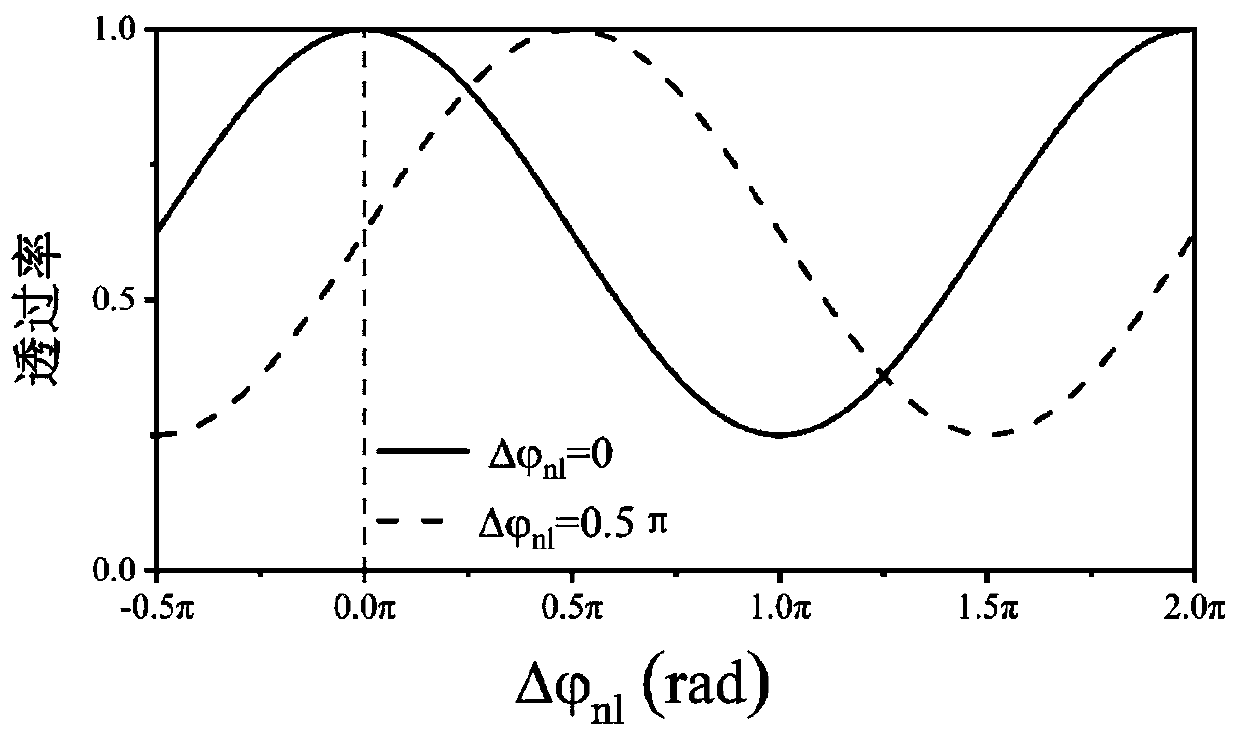

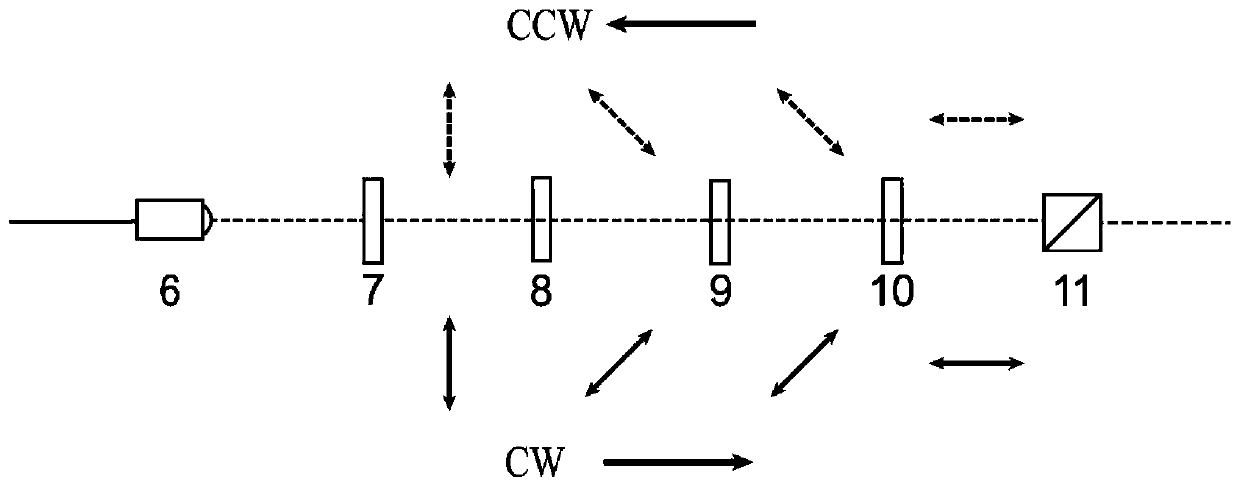

[0018] The high-repetition frequency all-polarization-maintaining 9-character cavity mode-locked laser involved in the present invention adopts a nonlinear amplifying ring mirror mode-locking mechanism. The fully polarization-maintaining 9-character cavity mode-locked laser is composed of an optical fiber part and a space part, such as figure 1 shown. The optical fiber part is directly welded by erbium-doped optical fiber 2 and wavelength division multiplexer 3 . A semiconductor diode with a wavelength of 980nm is used as a pumping source 1 and connected to the pumping end of a wavelength division multiplexer 3, and is input as a pumping source. The first fiber collimator 4 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com