Sealed microwell assay

A micropore and bead technology, applied in the field of micropore analysis assays, can solve the problems of difficult pairing, accuracy, ease of use and efficiency to be improved, etc., to increase the concentration, improve the ligand binding efficiency, and improve the accuracy. Effects of Sex and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1 - Microwell Analysis

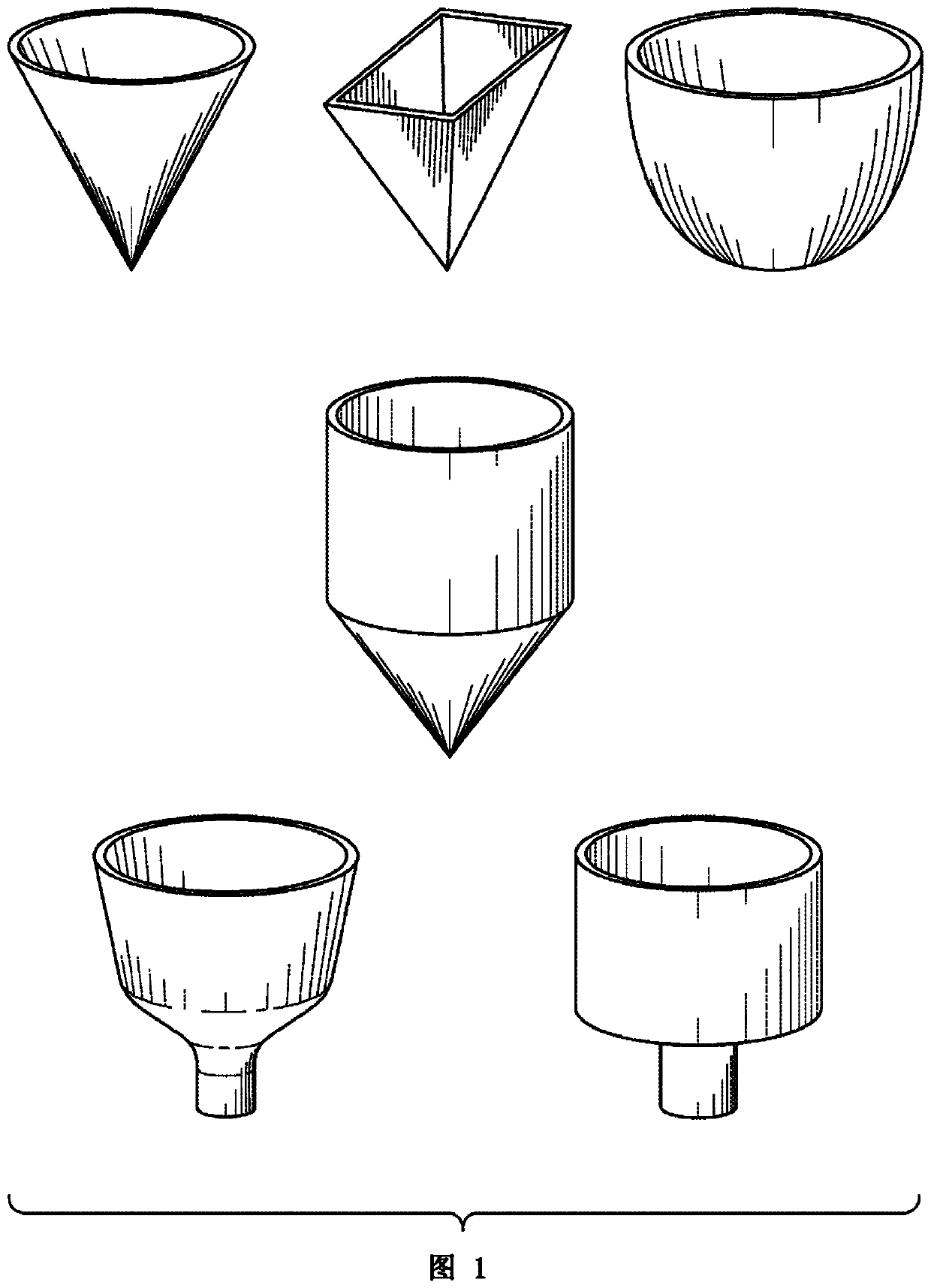

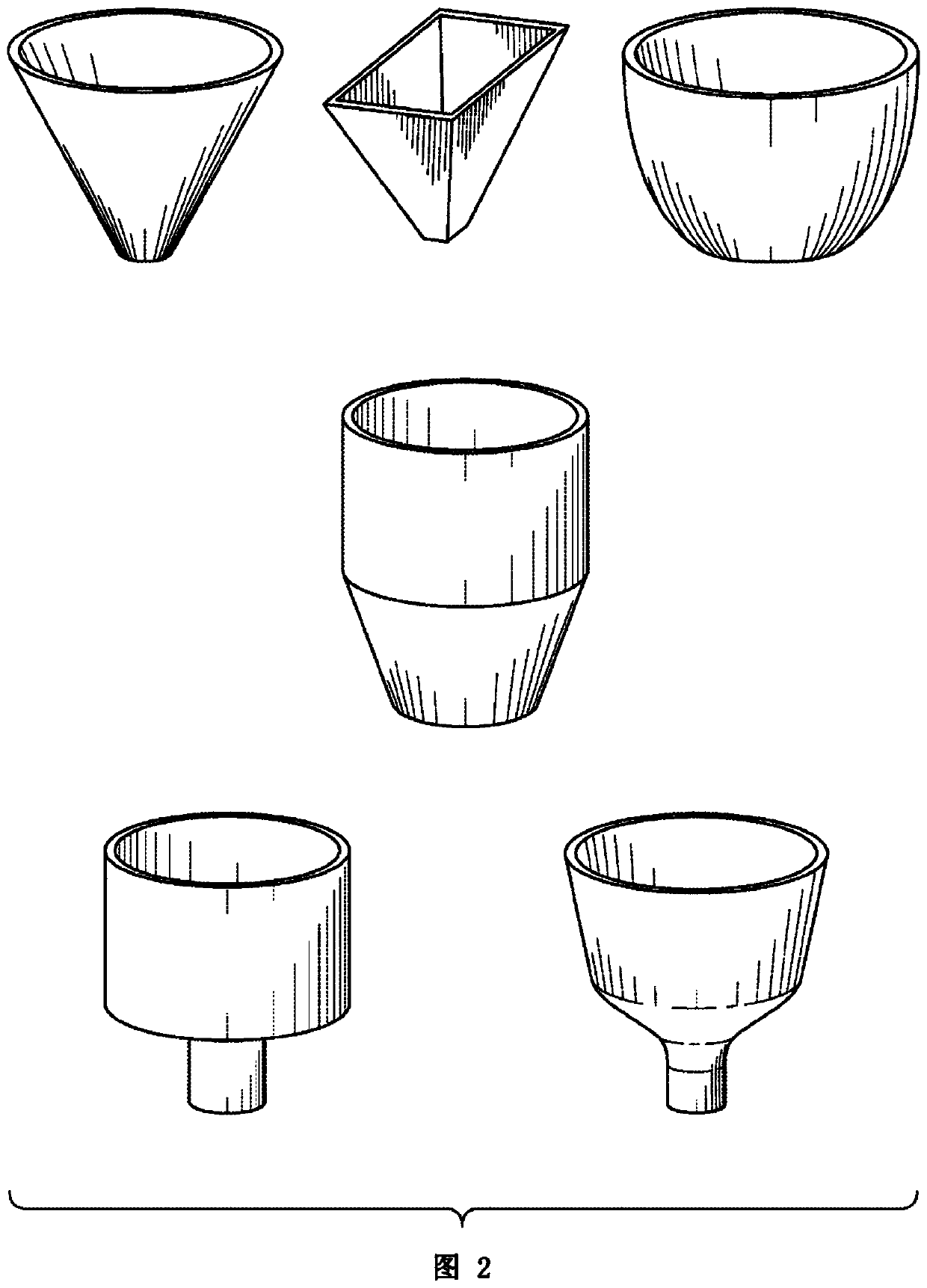

[0055] Use a series of microwells with a polygonal or conical frustoconical shape with a base diameter of 10–50 μm, a top diameter of 50–130 μm, and a height of 30–150 μm. The microwells are filled with culture medium and the cell suspension is loaded onto the array. The number ratio of cells to microwells is typically 1:10, while an effort is made to distribute the cells as evenly as possible over the entire array area. Allow sufficient time for the cells to settle to the bottom of the microwell. Thereafter, a nearly uniform suspension of beads ranging in diameter from 10-100 μm is loaded onto the microwell array, typically in a ratio of beads to microwells of 1.1:1 to 1.5:1. The surface of the beads is usually functionalized with oligonucleotides or antibodies to bind molecules released by the cells. Allow enough time for the beads to settle into the microwells and try to spread the beads as evenly as possible across the array to en...

Embodiment 2

[0056] Example 2 - Demonstration of Microporous Sealing

[0057] The practicality of sealing conical microwells with beads was tested in an experiment as Figure 11 , wherein the microwell has a conical cone shape with a bottom diameter of 140 μm, a depth of 200 μm, and an opening angle of 34°. The beads have a diameter of 225 μm and are made of hydrogel. Fill the microwell with fluorescein solution (a small molecule fluorescent dye with a molecular weight of 332 and a diffusion coefficient of 425 μm in water 2 / s), filling to a depth of 5mm. A suspension of beads is loaded onto the microwells and the beads are allowed to settle and fall into the wells. Exchange the medium in the microwells with normal buffer by repeated aspiration and dispensing of buffer. After repeating several times, no fluorescence was detected in the microwells without beads, while in the microwells with beads, the culture medium under the beads remained strongly fluorescent, which indicated the pres...

Embodiment 3

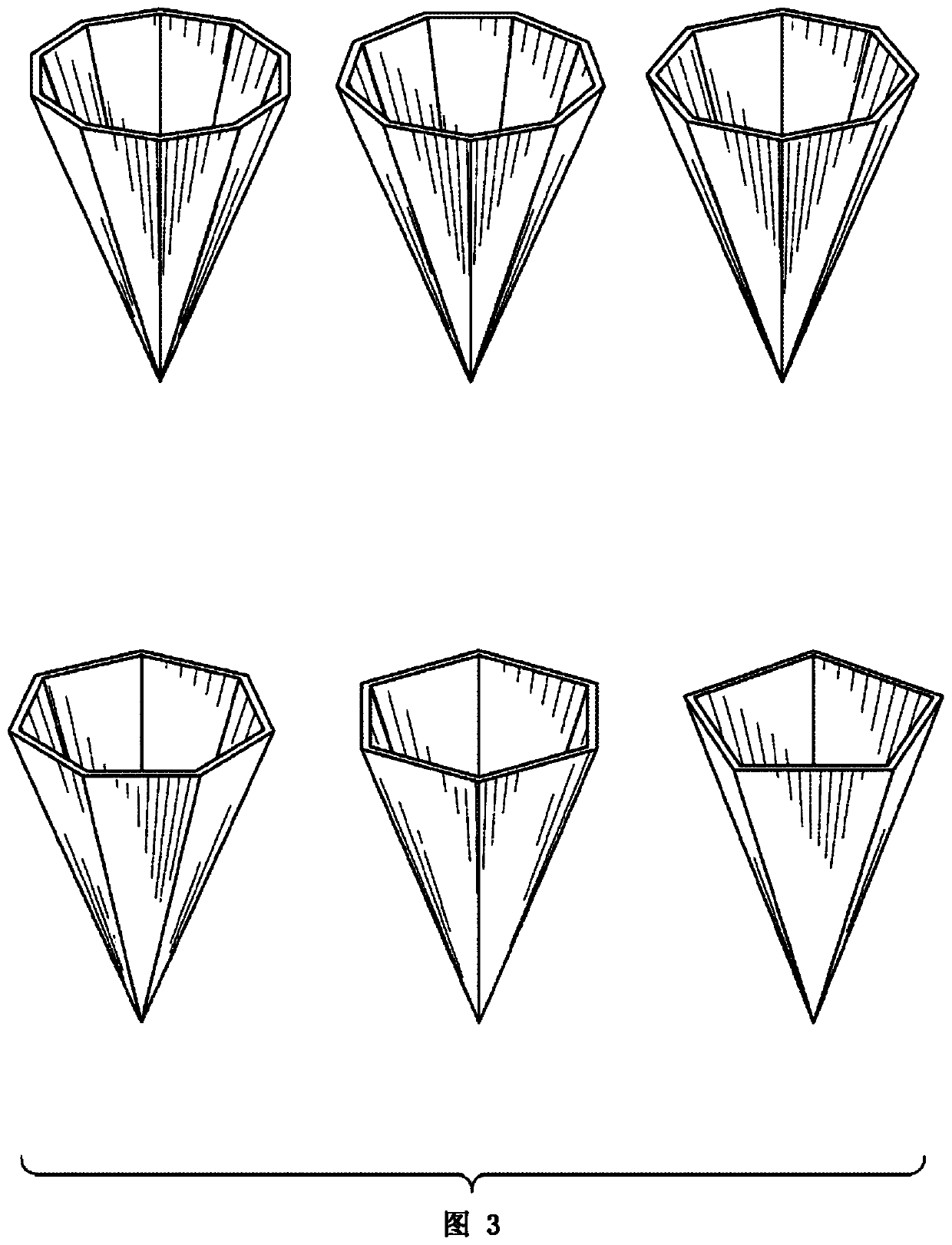

[0059] Example 3 - Demonstration of some advantages of conical microwells and microwell and bead geometry pairing

[0060] Configuring the wells to be conical ensures that only one bead enters each well. In testing of conical microwell arrays involving >10,000 monodisperse beads, more than one bead entering the well was never observed.

[0061] Additionally, when in a conical microwell, the beads rest on the conical sidewall and are positioned at a small, well-defined distance above the bottom of the microwell. When the parameters of the microwell and the diameter of the beads are chosen correctly, the medium volume between the bottom of the bead and the cell (or cells) at the bottom of the microwell can be minimized while avoiding unnecessary separation between the bead and the cell(s). physical contact. This feature makes the microwells of the invention advantageous for assays involving the hybridization of molecules released by cells or from lysed cells to molecules carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com