Powdery magnetic material segmented dry magnetic separation device and using method thereof

A dry magnetic separation and magnetic technology, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of low metal recovery rate and low grade of iron concentrate, and achieve the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

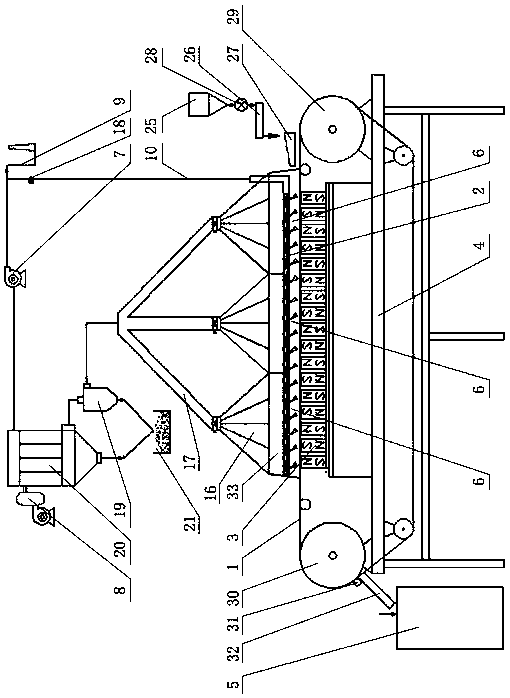

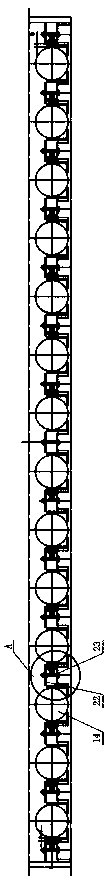

[0046] Take setting 3 sorting areas 6 as an example, such as figure 1 Said, from right to left (from the loading end to the unloading end) are the first selection area, the second selection area and the third selection area.

[0047] The air outlet of the air blowing pipe 14 is arranged along the width direction of the belt 1 , parallel to the surface of the belt 1 and a low field strength area 7-12 mm away from the surface of the belt 1 . Each blowing mechanism is provided with 14-20 blowing pipes 14 .

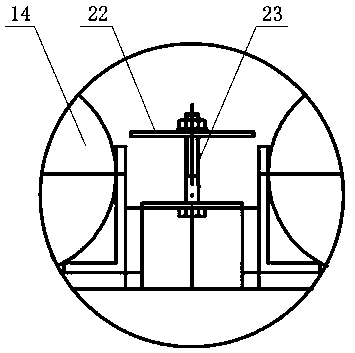

[0048] The grille 23 adopts a carbon steel screen with an aperture of 1-2mm. The grille 23 is fixed on the frame 4; The grille 23 is articulated and its length is 15-25mm.

[0049] The materials of the magnet blocks in the magnetic system 3 are neodymium iron boron and strontium ferrite.

[0050] The adjusting valve 18 is used to adjust the air circulation amount, and the excess air is exhausted through the exhaust pipe 9 .

[0051] The magnetic field strength is stronger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com