Feeding conveying system and method for melting reduction furnace

A technology of conveying system and reduction furnace, which is applied in the direction of conveyor, conveying bulk materials, transportation and packaging, etc. It can solve problems such as unsmooth feeding, material blockage, powder sequence control error, etc., and achieves low equipment investment and flexible operation , not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

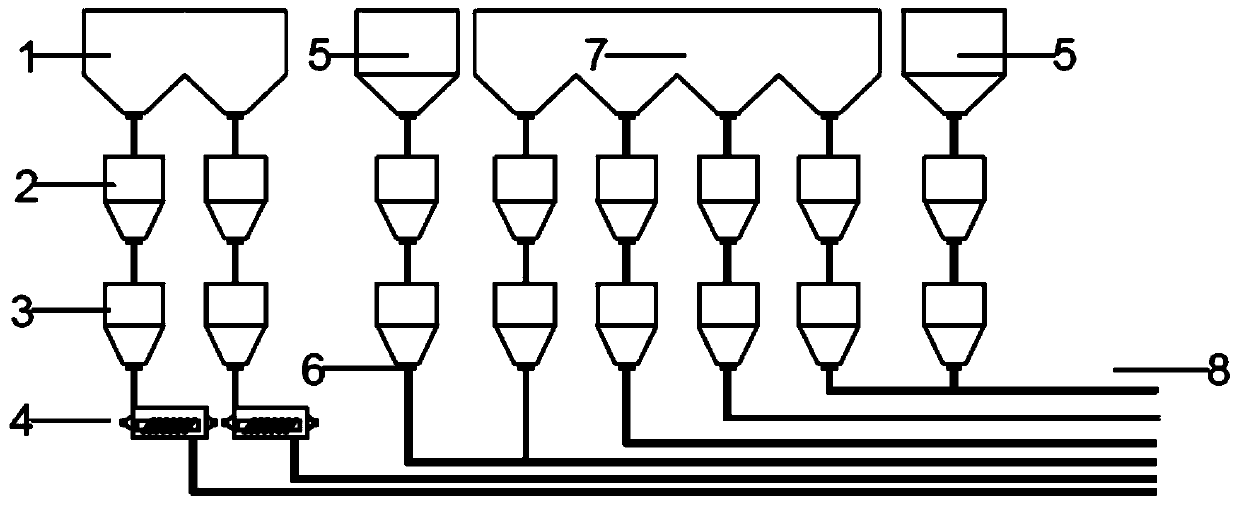

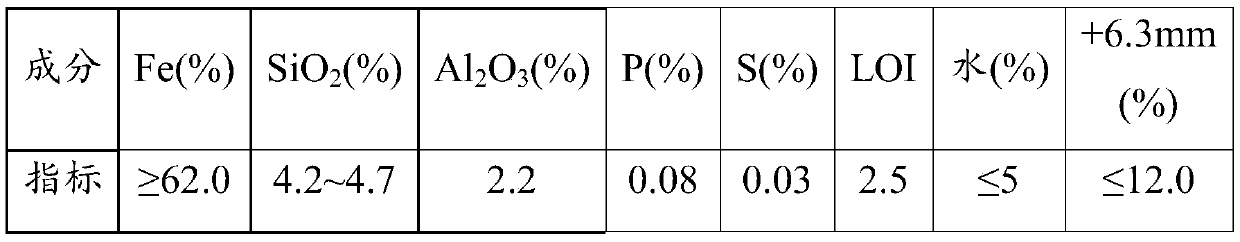

[0025] The technical problem to be solved by the embodiments of the present invention is to provide a feeding and conveying system for smelting reduction furnaces. , Dolomite powder feeding conveying system. The pulverized coal adopts 4 sets of stringing tank systems, which are fed through the dry coal bunker, tundish, and injection tank, and fed by the rotary feeder; Unloading, feeding by rotary feeder, connected to two pulverized coal injection pipelines nearby; iron ore powder and dolomite powder adopt 2 sets of series tank system, unloading through hot ore bin, intermediate tank, injection tank, screw feeding The material is fed by the feeder, and the material in the hot ore bin is iron ore powder and dolomite powder mixed in proportion, dried and heated powder. Using nitrogen as the carrier gas, the hot ore, coal powder, and flux pipelines are merged before entering the spray gun, and the injection pipelines of the three systems are finally merged into two pipelines in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com