Preparation method of novel ultraviolet resistant copolymerized polycarbonate

A technology of polycarbonate and polycarbonate copolycarbonate, which is applied in the field of preparation of new anti-ultraviolet copolycarbonate, can solve the problems of poor compatibility, affecting the mechanical properties of composite materials, and poor dispersion of anti-ultraviolet agents. Achieve the effects of improving mechanical properties, improving UV resistance, and ensuring consistency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

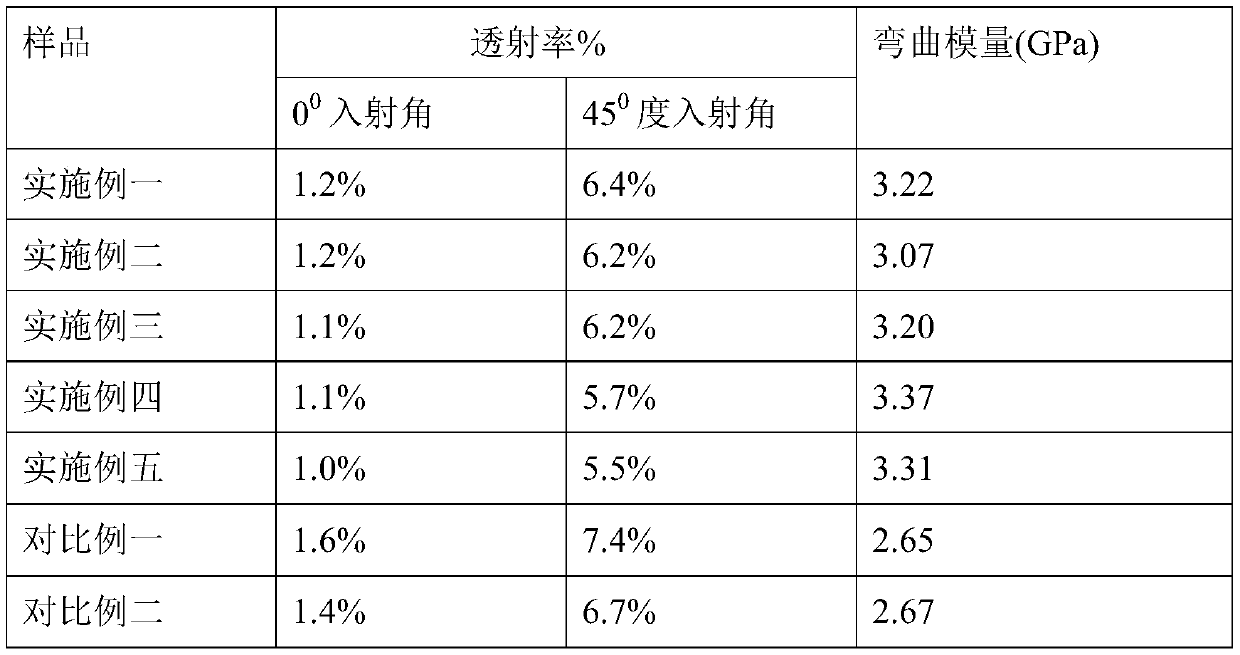

Examples

Embodiment 1

[0031] (a) Diphenyl carbonate (DPC) is first placed in a reaction kettle with a nitrogen protection device, heated to melt it, and then add 4,4'-dihydroxybenzophenone anti-ultraviolet agent and bisphenol A ( BPA), DPC, BPA and anti-ultraviolet agent (molar ratio n (DPC): n (BPA): n (anti-ultraviolet agent) = 1.02:0.7:0.3), stir well, add tert-butyl potassium catalyst, catalyst and BPA The molar ratio is 1: (1×10 -4 ), after melting the ingredients, add them together to the reaction kettle equipped with a temperature controller, agitator and nitrogen protection device, adjust the stirring rate to 800r / min, and react for 4h at a temperature of 200°C; (b) adjust the temperature to 250 °C, the stirring rate was adjusted to 600r / min, and the reaction was carried out for 2 hours to obtain an anti-ultraviolet copolymerized polycarbonate.

Embodiment 2

[0033] (a) Diphenyl carbonate (DPC) is first placed in a reaction kettle with a nitrogen protection device, heated to melt it, and then add 4,4'-dihydroxybenzophenone anti-ultraviolet agent and bisphenol A ( BPA), DPC, BPA and anti-ultraviolet agent (molar ratio n (DPC): n (BPA): n (anti-ultraviolet agent) = 1.1: 0.75: 0.35), stir well, add tert-butyl cesium catalyst, catalyst and BPA The molar ratio is 1:(3.5×10 -4 ), after melting the ingredients, add them together to the reaction kettle equipped with a temperature controller, agitator and nitrogen protection device, adjust the stirring rate to 600r / min, and react for 2h at a temperature of 220°C; (b) adjust the temperature to 260 °C, the stirring rate was adjusted to 400r / min, and the reaction was carried out for 0.5h to obtain an anti-ultraviolet copolymerized polycarbonate.

Embodiment 3

[0035] (a) Diphenyl carbonate (DPC) is first placed in a reaction kettle with a nitrogen protection device, heated to melt it, and then add 4,4'-dihydroxybenzophenone anti-ultraviolet agent and bisphenol A ( BPA), DPC, BPA and anti-ultraviolet agent (molar ratio n (DPC): n (BPA): n (anti-ultraviolet agent) = 1.08: 0.72: 0.32), stir well, add tert-butyl sodium catalyst, catalyst and BPA The molar ratio is 1: (3×10 -4 ), after melting the ingredients, add them together to a reaction kettle equipped with a temperature controller, a stirrer and a nitrogen protection device, adjust the stirring rate to 700r / min, and react for 3h at a temperature of 230°C; (b) adjust the temperature to 290 °C, the stirring rate was adjusted to 500r / min, and the reaction was carried out for 1.5h to obtain an anti-ultraviolet copolymerized polycarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com