Remote fault diagnosis and push method and device for robot

A fault diagnosis and robotics technology, applied to instruments, manipulators, computer parts, etc., can solve problems such as remote monitoring of faults, low maintenance efficiency, etc., to achieve accurate fault diagnosis, increase response speed, and improve computing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

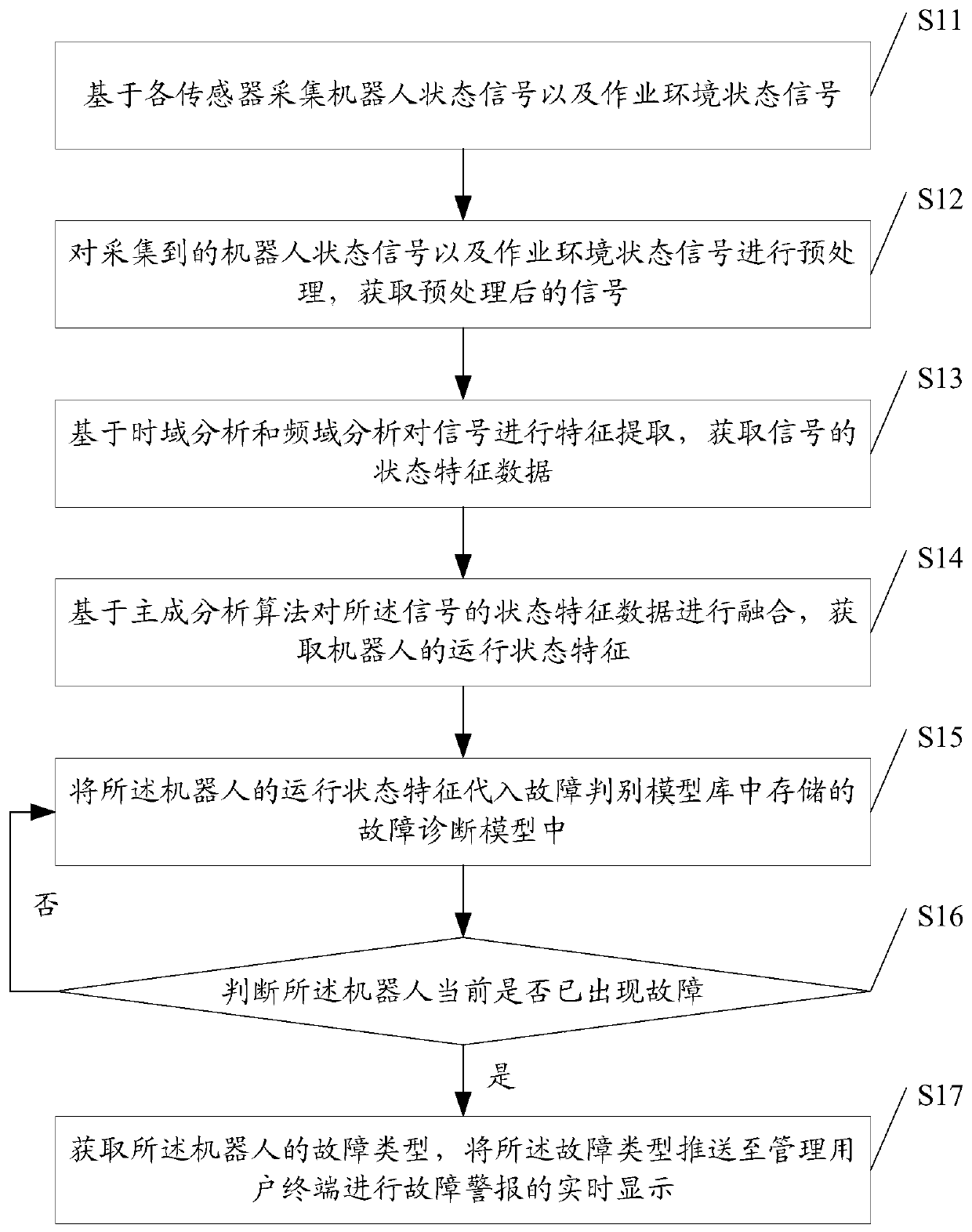

[0055] see figure 1 , figure 1 It is a schematic flow chart of the push method for remote fault diagnosis of the robot in the embodiment of the present invention.

[0056] Such as figure 1 As shown, a remote fault diagnosis pushing method of a robot, the method includes:

[0057] S11: collect robot status signals and operating environment status signals based on each sensor;

[0058] In the specific implementation process of the present invention, the robot status signal includes current status signal, rotation angle signal, position signal, speed signal, angular velocity signal, acceleration signal, vibration signal and shaft temperature signal; the working environment status signal includes: ambient temperature signal, ambient humidity signal, and ambient noise signal.

[0059] Specifically, different sensors are installed on different key components of the robot and the surrounding environment, for example, sensors for collecting current, sensors for collecting angular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com