Stacking robot driving method and driving system

A technology for palletizing robots and driving methods, which is applied in the field of palletizing robot driving methods and driving systems, can solve problems such as low control accuracy, and achieve the effects of ensuring real-time performance, high cost performance, and good control flexibility characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

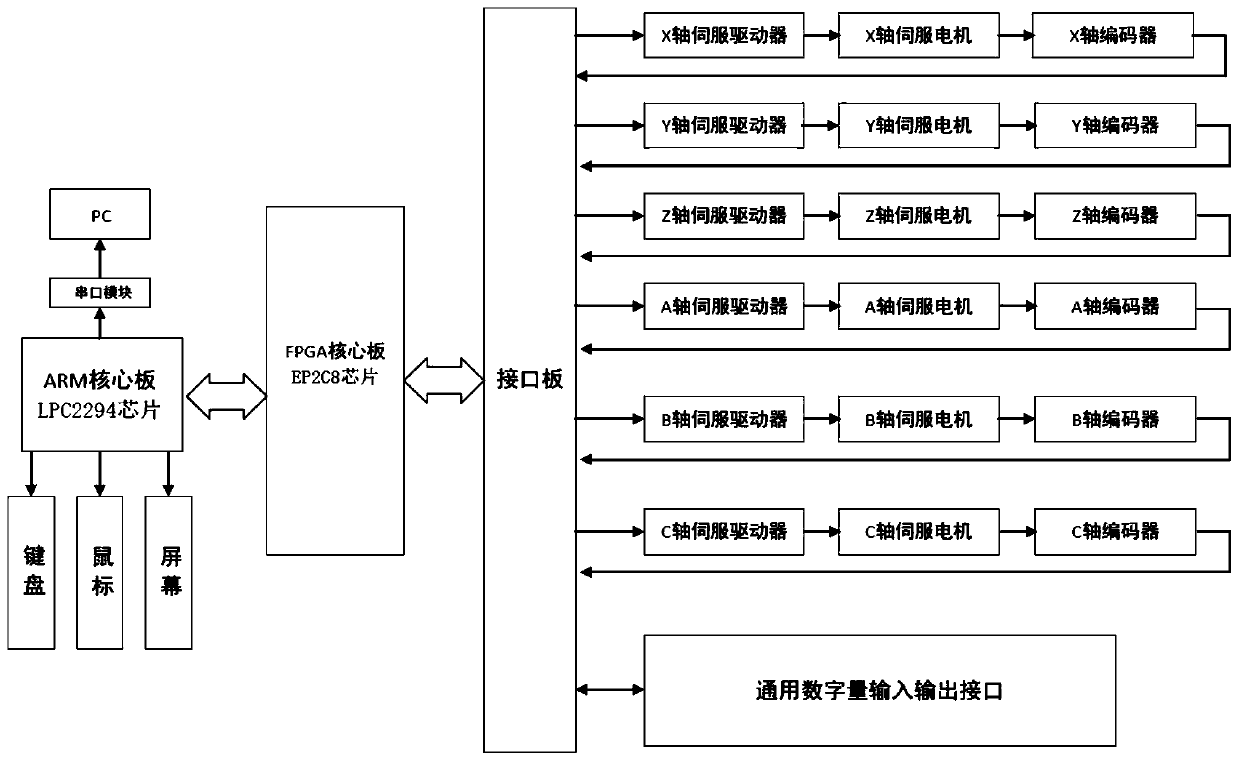

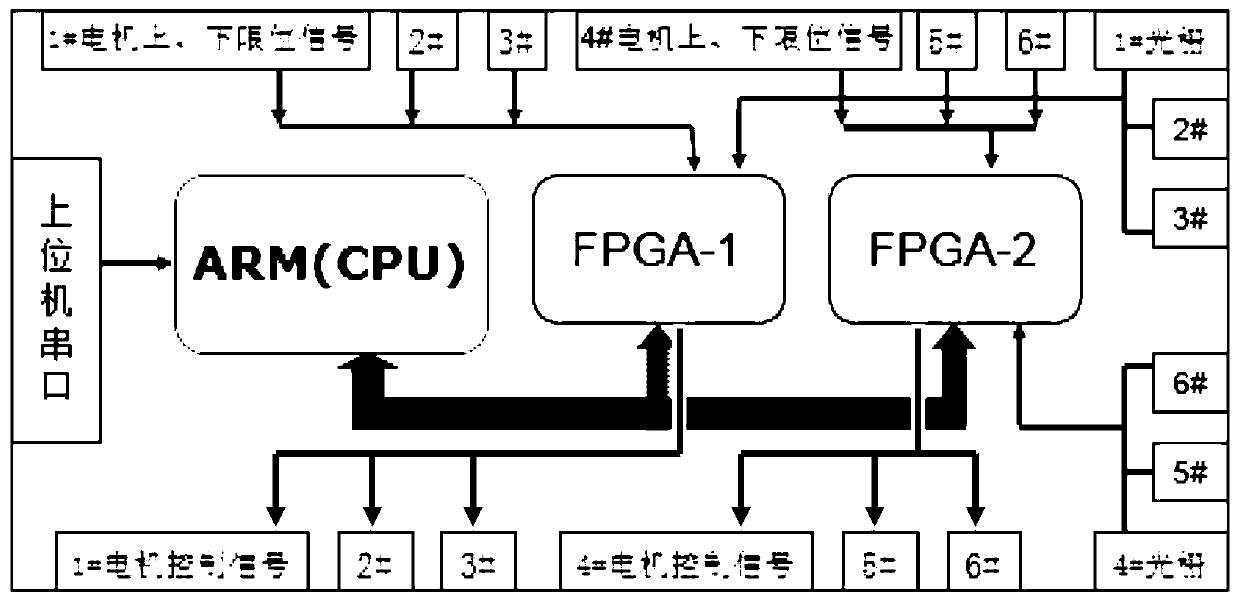

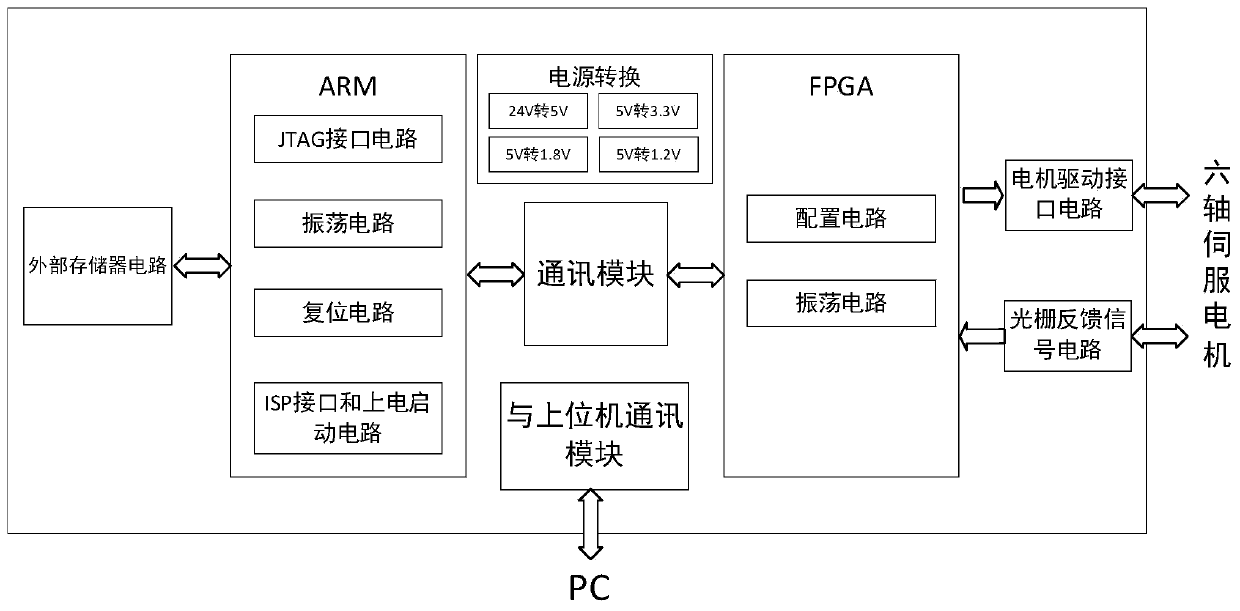

[0061] Such as figure 1As shown, the applicable stacking robot structure of the present invention: X, Y, Z, A, B, C six-axis stacking robot driver card based on Altera EP2C8 series FPGA chips and ARM7TDMI-S series LPC2294 chips, applied to cigarettes A robot for unpacking and palletizing cigarette boxes in the silk production line. ARM is responsible for command or data interaction with the host computer, FPGA is used for motor control signal transmission and grating signal processing, through motor signal control, grating closed-loop feedback signal processing, limit switch and other modules to realize the function of unpacking and stacking the cigarette box . In the palletizing robot based on this architecture, the ARM compiles the program dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com