Anti-radiation cloth and preparation method thereof

A technology of radiation protection and radiation protection layer, applied in the field of fabric processing, can solve the problems of radiation layer falling off, poor water resistance, poor flexibility, etc., and achieve the effects of good waterproof effect, simple preparation method and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of anti-radiation cloth, prepares anti-radiation cloth as above, comprises the following steps:

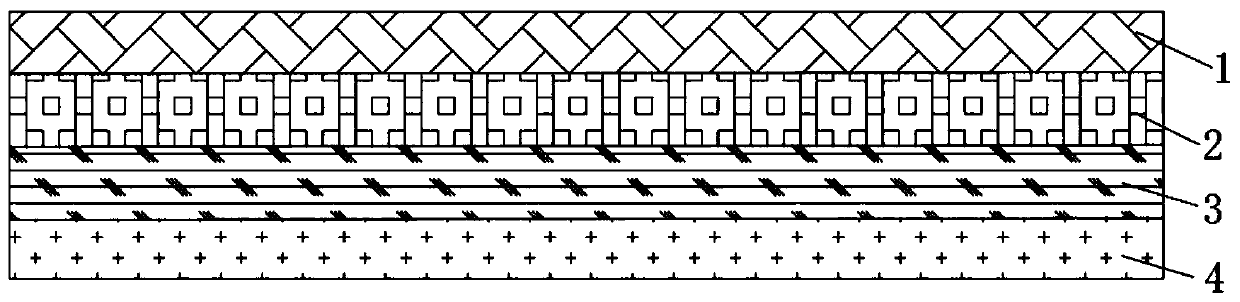

[0028] (1) The anti-wrinkle layer 1 can be obtained by weaving 50 parts of warp threads with memory fibers, 50 parts of weft threads and 1 part of melamine fibers through a textile machine;

[0029] (2) Spin 10 parts of polyester, 25 parts of rayon and 25 parts of cotton fiber through a textile machine, and the specification of the obtained thread is 20-30 nm;

[0030] (3) Mix the textile thread obtained in step (2) with polytetrafluoroethylene at a weight ratio of 10:1 to prepare the waterproof layer 2;

[0031] (4) The textile thread obtained in step (2) and the nano-silver and nano-titanium dioxide composite with a weight ratio of 2:1 are mixed with a textile machine, and the weight ratio of the textile thread to the composite of nano-silver and nano-titanium dioxide is 10:1, the radiation protection layer 3 can be obtained;

[0032] (5) We...

Embodiment 2

[0036] A preparation method of anti-radiation cloth, comprising the following steps:

[0037] (1) The anti-wrinkle layer 1 can be obtained by weaving 50 parts of warp threads, 50 parts of weft threads and 5 parts of melamine fibers with memory fibers on a textile machine;

[0038] (2) Spin 20 parts of polyester, 45 parts of rayon and 60 parts of cotton fiber through a textile machine, and the specification of the obtained thread is 20-30 nm;

[0039] (3) Mix the textile thread obtained in step (2) with polytetrafluoroethylene at a weight ratio of 10:1 to prepare the waterproof layer 2;

[0040] (4) The textile thread obtained in step (2) and the nano-silver and nano-titanium dioxide composite with a weight ratio of 2:1 are mixed with a textile machine, and the weight ratio of the textile thread to the composite of nano-silver and nano-titanium dioxide is 10:1, the radiation protection layer 3 can be obtained;

[0041] (5) Weaving the textile thread obtained in step (2) with ...

Embodiment 3

[0045] A preparation method of anti-radiation cloth, comprising the following steps:

[0046] (1) The anti-wrinkle layer 1 can be obtained by weaving 50 parts of warp threads, 50 parts of weft threads and 3 parts of melamine fibers with memory fibers on a textile machine;

[0047] (2) Spin 15 parts of polyester, 35 parts of rayon and 40 parts of cotton fiber through a textile machine, and the specification of the obtained thread is 20-30 nm;

[0048] (3) Mix the textile thread obtained in step (2) with polytetrafluoroethylene at a weight ratio of 10:1 to prepare the waterproof layer 2;

[0049] (4) The textile thread obtained in step (2) and the nano-silver and nano-titanium dioxide composite with a weight ratio of 2:1 are mixed with a textile machine, and the weight ratio of the textile thread to the composite of nano-silver and nano-titanium dioxide is 10:1, the radiation protection layer 3 can be obtained;

[0050] (5) Weaving the textile thread obtained in step (2) with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com