An open press connected automatic loading and unloading system and its application

An open press and in-line technology, which is applied in the field of open press in-line automatic loading and unloading systems, can solve the problems of simultaneous continuous operation of multiple points, low efficiency, and inability to meet assembly line operations, etc., to achieve Save production labor and time, save costs, and control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

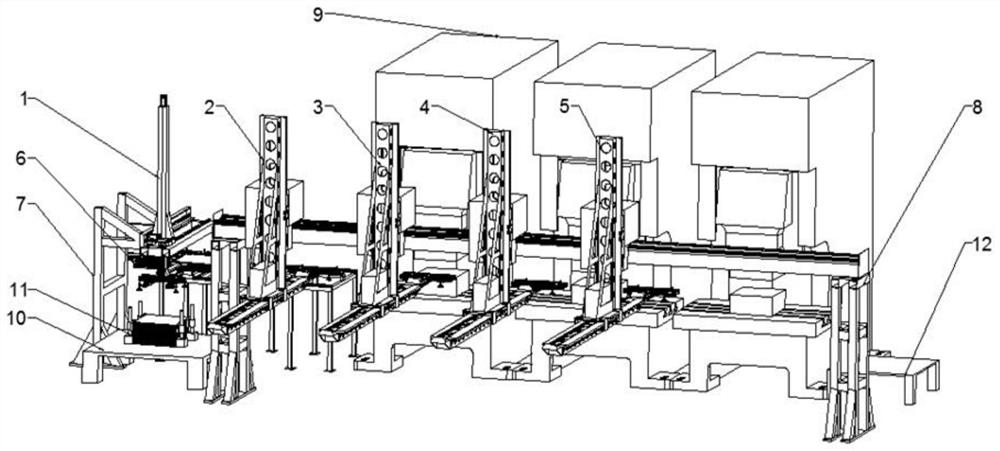

[0051] Such as Figure 1-9 As shown, the present embodiment provides an open press connected automatic loading and unloading system, which mainly includes three parts: a reclaiming manipulator 1, a centering platform 6, and a loading and unloading manipulator;

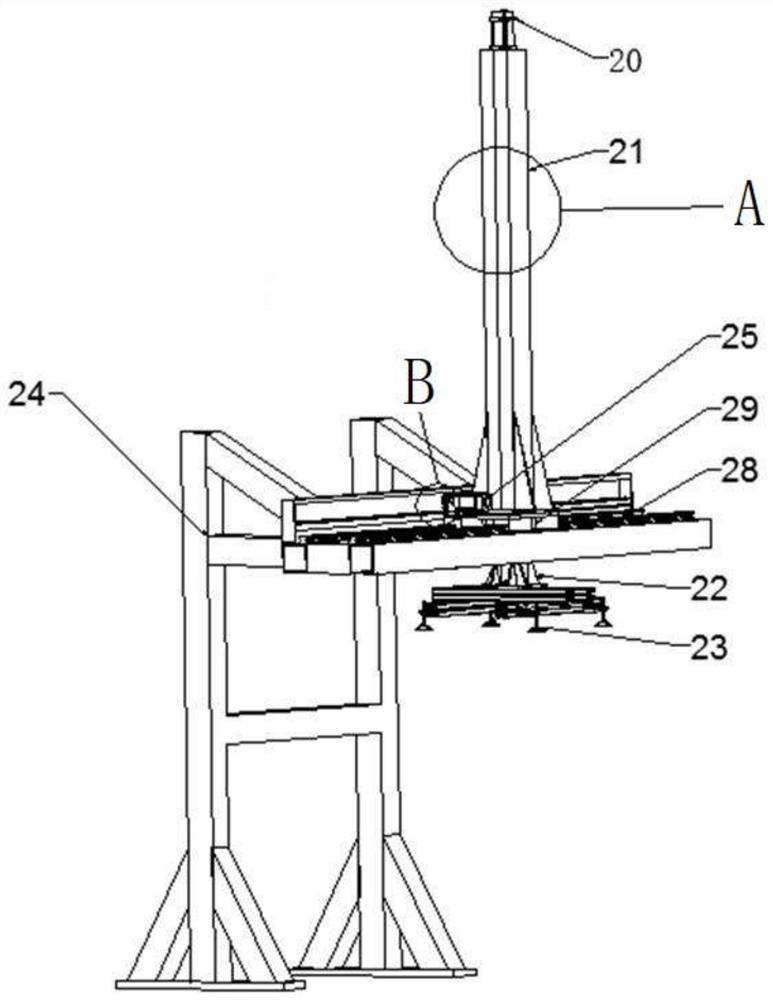

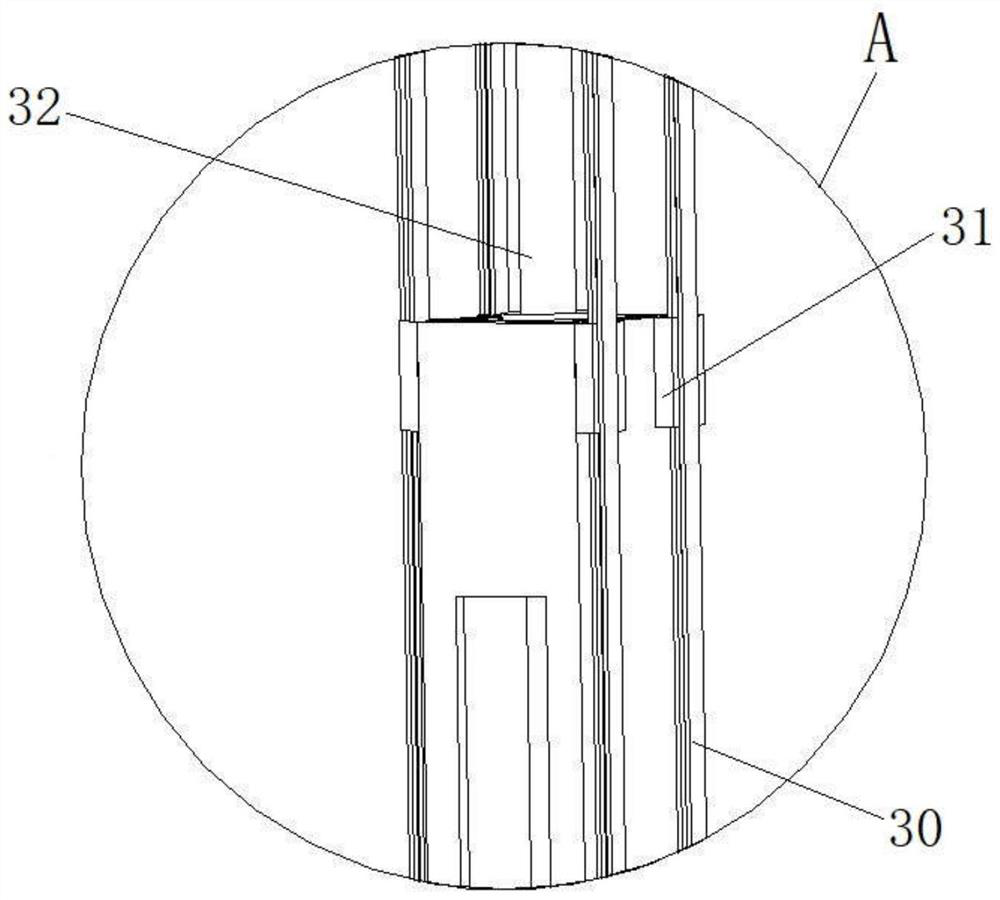

[0052] The retrieving manipulator 1 includes a reclaiming manipulator support 7, a sliding device and a lifting device, the sliding device is arranged on the reclaiming manipulator support 7, the lifting device is arranged on the sliding device, and the bottom end of the lifting device is provided with a grabber;

[0053] The centering platform 6 includes a centering platform support 47, a centering platform frame 45 and a centering device, and the centering platform frame 45 realizes movement on the centering platform bracket 47 through a driving device, and the centering device is arranged on the centering platform frame 45 to realize the centering adjustment of the workpiece;

[0054] The loading and unloading mani...

Embodiment 2

[0067] A connected automatic loading and unloading system for an open press, the structure of which is as described in Embodiment 1, the difference is that a hydraulic motor is used as the driving source.

Embodiment 3

[0069] A working method for an open-type automatic loading and unloading system of an open press machine, using the system solution described in Embodiment 1 to perform multi-process operations on three open-type open presses with multiple processes, and in advance on the pallet support of the loading table 10 After the system is started, each part works according to the PLC program. The working method includes the following steps:

[0070] (1) material retrieving manipulator: the grabber is moved to the top of the workpiece material stack by the operation of the material retrieving horizontal motor 25, and then the grabber is lowered to contact the top workpiece of the workpiece material stack through the operation of the material retrieving vertical motor 20;

[0071] (2) The high-voltage sucker 23 of the grabber starts to grab the workpiece, and then the vertical motor 20 and the horizontal motor 25 work again to make the high-voltage sucker 23 move to the top of the centeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com