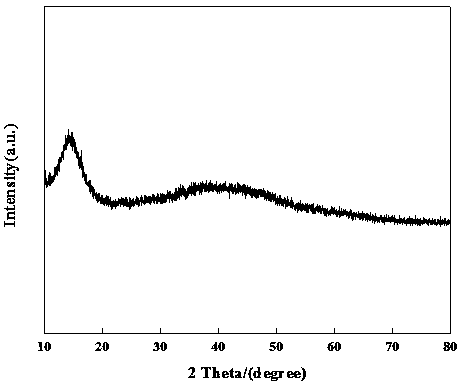

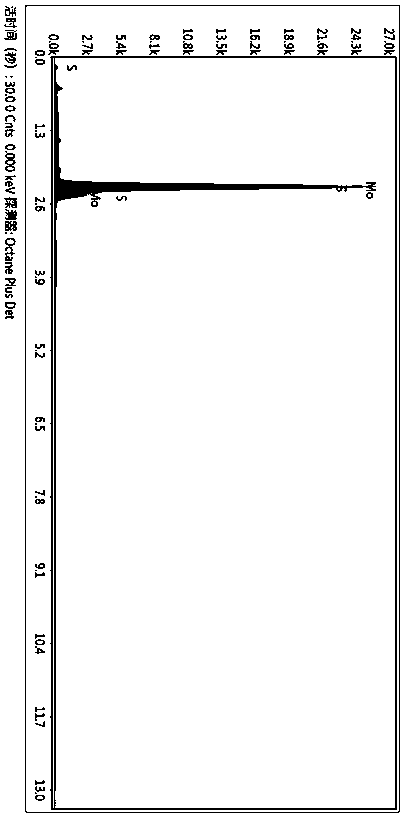

Preparation method for high-rate-performance sulfur-like positive electrode material namely molybdenum polysulfide nanosheet

A sulfur cathode material, high-rate technology, applied in the field of preparation of electrode materials, can solve the problems of large volume changes, and achieve the effects of high purity, excellent lithium storage performance, and easy synthesis and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing molybdenum polysulfide nanosheets of sulfur-like cathode material with high rate performance, comprising the following steps:

[0020] 1) Add 4g (NH 4 ) 6 Mo 7 o 24 • 4H 2 O was dissolved in 80 mL of deionized water by heating to obtain a clear solution, then 40 mL of saturated ammonium polysulfide solution was added to the above clear solution and stirred to mix evenly, then the mixed solution was transferred to a conical flask and heated at 80°C After 5 h, filter at hot temperature;

[0021] 2) After the above filtrate is cooled to room temperature, add 20mL saturated ammonium polysulfide solution, stir to make it evenly mixed, then place it airtightly at room temperature for 18h, then centrifuge to obtain black crystals, and then use water, absolute ethanol, CS 2 and anhydrous ether, and finally dried in vacuum at 80°C for 10 h to obtain the precursor of molybdenum polysulfide nanosheets (NH 4 ) 2 Mo 2 S 12 • 2H 2 O(ATDM).

[0022] 3...

Embodiment 2

[0029] A method for preparing molybdenum polysulfide nanosheets of sulfur-like cathode material with high rate performance, comprising the following steps:

[0030] 1) Mix 6g (NH 4 ) 6 Mo 7 o 24 • 4H 2 O was dissolved in 100 mL of deionized water by heating to obtain a clear solution, and then 20-60 mL of saturated ammonium polysulfide solution was added to the above clear solution and stirred to make it evenly mixed, then the mixed solution was transferred to a conical flask, and mixed at 100 After heating at ℃ for 8 h, filter at hot temperature;

[0031] 2) After the above filtrate is cooled to room temperature, add 24mL saturated ammonium polysulfide solution, stir to mix evenly, and then place it airtightly at room temperature for 20h, then centrifuge to obtain black crystals, and then use water, absolute ethanol, CS 2washed with anhydrous ether, and finally dried under vacuum at 90°C for 12 h to obtain the precursor of molybdenum polysulfide nanosheets (NH 4 ) 2 Mo...

Embodiment 3

[0034] A method for preparing molybdenum polysulfide nanosheets of sulfur-like cathode material with high rate performance, comprising the following steps:

[0035] 1) Mix 2g (NH 4 ) 6 Mo 7 o 24 • 4H 2 O was dissolved in 40 mL of deionized water by heating to obtain a clear solution, then 20 mL of saturated ammonium polysulfide solution was added to the above clear solution and stirred to mix evenly, then the mixed solution was transferred to a conical flask, and heated at 70°C for 3 hours Afterwards, filter at hot temperature;

[0036] 2) After the above filtrate is cooled to room temperature, add 18mL saturated ammonium polysulfide solution, stir to mix evenly, and then place it airtightly at room temperature for 12h, then centrifuge to obtain black crystals, and then use water, absolute ethanol, CS 2 washed with anhydrous ether, and finally dried under vacuum at 50°C for 8 h to obtain the precursor of molybdenum polysulfide nanosheets (NH 4 ) 2 Mo 2 S 12 • 2H 2 O(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com