A special calcium-based powder modification device and modification method for adhesives

A calcium-based powder and adhesive technology, which is applied in the field of special calcium-based powder modification devices for adhesives, can solve the problems of poor uniformity of the powder surface modifier, and achieves the advantages of avoiding excessive storage time, stable quality, and improved technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

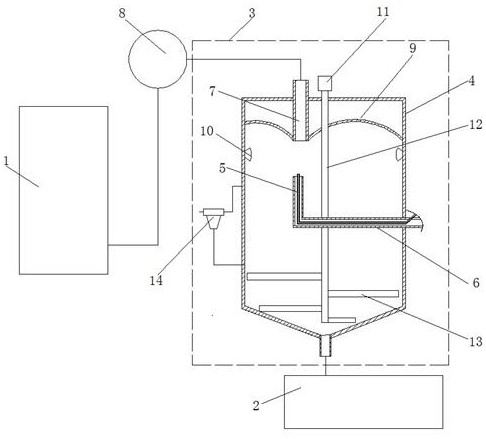

[0026] This implementation discloses a special calcium-based powder modification device for adhesives, including a grinder 1, a kneader 2 connected to the grinder 1, and a mixing device 3 arranged between the grinder 1 and the kneader 2. The mixing The device 3 includes a mixing chamber 4, a modifying agent nozzle 5, a hot high-pressure air nozzle 6, and a powder nozzle 7. The powder nozzle 7 is located at the top of the mixing chamber 4 and one end extends into the mixing chamber 4, and the other end passes through the A high-speed airflow disperser 8 is connected with the grinder 1, the hot high-pressure jet pipe 6 is located directly below the powder jet pipe 7, the nozzle of the powder jet pipe 7 is opposite to the hot high-pressure jet pipe 6 nozzle, and the modified One end of the agent spray pipe 5 extends into 6 positions of the hot high-pressure air spray pipe, and the nozzle of the modifier nozzle 5 is 2-3 cm higher than the 6 nozzles of the hot high-pressure air spra...

Embodiment 2

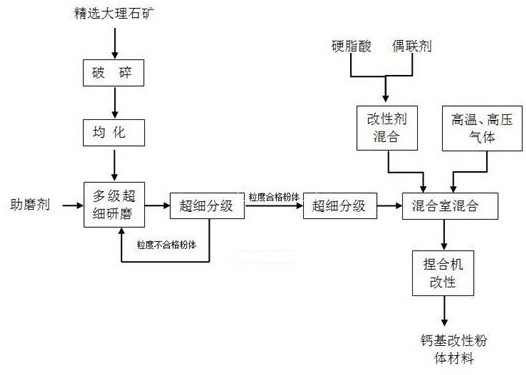

[0035] This embodiment discloses a calcium-based powder modification method for adhesives as follows, including using the modification device described in Embodiment 1;

[0036] Specifically include the following steps,

[0037] S1: Put the pulverized and homogenized calcium carbonate into the grinder 1 for grinding;

[0038] S2: The ground powder enters the mixing chamber 4 to be mixed with the modifier;

[0039] S3: The mixed powder enters the kneader 2 for kneading modification.

[0040] Among them, in S1, the grinder 1 grinds calcium carbonate to 2900 mesh, and in S2, the hot high-pressure gas ejected from the hot high-pressure gas injection pipe 6 in the mixing chamber 4 is T=95°C, P=2.5Mpa.

[0041] Wherein, the modifying agent in S2 includes 10 parts of stearic acid, 5 parts of silane coupling agent, 4 parts of titanate coupling agent, and 1 part of aluminate coupling agent, and the modifier is mixed before use. Mixed preparations.

[0042]Among them, in S3, after t...

Embodiment 3

[0046] This embodiment is further optimized on the basis of Embodiment 2, wherein, in S1, the grinding machine 1 grinds calcium carbonate to 2800 mesh, and in S2, the hot high-pressure gas ejected from the hot high-pressure gas injection pipe 6 in the mixing chamber 4 T=90°C, P=2Mpa.

[0047] Wherein, the modifying agent in S2 includes 15 parts of stearic acid, 6 parts of silane coupling agent, 5 parts of titanate coupling agent, and 3 parts of aluminate coupling agent.

[0048] Example 3

[0049] This embodiment is further optimized on the basis of Embodiment 2, wherein, in S1, the grinding machine 1 grinds calcium carbonate to 3000 meshes, and in S2, the hot high-pressure gas ejected from the hot high-pressure gas injection pipe 6 in the mixing chamber 4 T=100°C, P=3Mpa.

[0050] Wherein, the modifying agent in S2 includes 20 parts of stearic acid, 8 parts of silane coupling agent, 6 parts of titanate coupling agent, and 5 parts of aluminate coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com