A kind of preparation method of rare earth garnet single crystal

The technology of garnet and yttrium iron garnet is applied in the field of preparation of rare earth garnet single crystal, which can solve the problems of deviation of melt composition, low solute content, lower growth temperature, etc., so as to avoid the deviation of single crystal composition, Overcome the effect of severe component deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

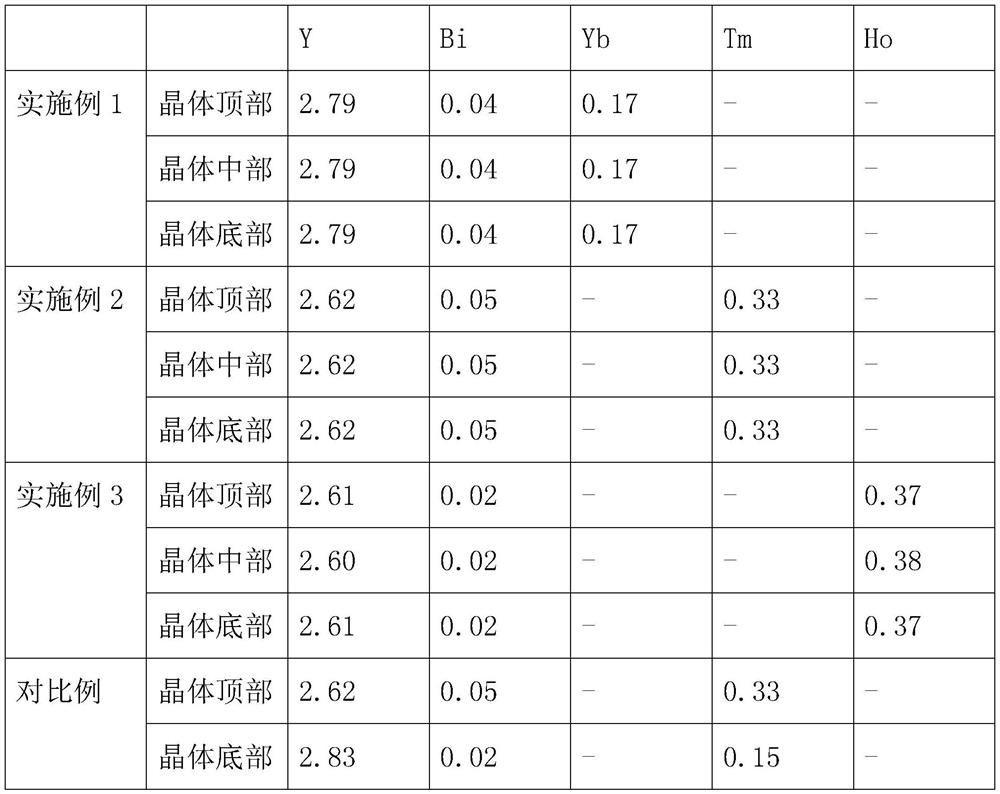

Examples

Embodiment 1

[0023] A preparation method of rare earth garnet single crystal adopts multi-layer thickening method, comprising the following steps:

[0024] (1) Preparation of polycrystalline material: according to the crystal molecular formula Y (2.9-x) Yb x Bi 0.1 Fe 5 o 12 , where x=0.2, according to the molar ratio, respectively weigh Y with a purity ≥99.99% 2 o 3 、 Bi 2 o 3 , Yb 2 o 3 and Fe2O3 raw material, namely Yb 2 o 3 : Bi 2 o 3 :Y 2 o 3 :Fe 2 o 3 =0.2:0.1:2.7:5 Weigh 500g, place the weighed raw materials in an agate mortar and grind them thoroughly for 2 hours to obtain a mixed powder raw material; place the mixed powder raw material at a temperature of 1100°C Pre-fired for 12 hours, then ground for 2 hours to obtain YIG polycrystalline material;

[0025] (2) Add flux: add PbO-B in the YIG polycrystalline material that obtains in step (1) 2 o 3 Composite flux, wherein the mass ratio is YIG polycrystalline material: Fe2O3: PbO: B2O3 = 1.68:5.44:90.81:2.07, and...

Embodiment 2

[0033] A preparation method of rare earth garnet single crystal adopts multi-layer thickening method, comprising the following steps:

[0034] (1) Preparation of polycrystalline material: according to the crystal molecular formula Y (2.9-x) T mx Bi 0.1 Fe 5 o 12 , where x=0.35, according to the molar ratio, respectively weigh Y with a purity ≥99.99% 2 o 3 、 Bi 2 o 3 、Tm 2 o 3 and Fe 2 o 3 Raw material, ie Tm 2 o 3 : Bi 2 o 3 :Y 2 o 3 :Fe 2 o 3 =0.35:0.1:2.55:5 Weigh 500g, place the weighed various raw materials in an agate mortar and grind them fully for 2.5h to uniformity to obtain the mixed powder raw materials; and place the mixed powder raw materials at a temperature of 1300 Pre-fire at ℃ for 12 hours, then grind for 2 hours to obtain YIG polycrystalline material;

[0035] (2) Add flux: add PbO-B in the YIG polycrystalline material that obtains in step (1) 2 o 3 Composite flux, wherein the mass ratio is YIG polycrystalline material: Fe 2 o 3 :PbO:B ...

Embodiment 3

[0043] A preparation method of rare earth garnet single crystal adopts multi-layer thickening method, comprising the following steps:

[0044] (1) Preparation of polycrystalline material: according to the crystal molecular formula Y (2.9-x) Ho x Bi 0.1 Fe 5 o 12 , where x=0.4, respectively weigh Y with a purity ≥99.99% according to the molar ratio 2 o 3 、 Bi 2 o 3 , Ho2O3 and Fe2O3 raw materials, namely Ho 2 o 3 : Bi 2 o 3 :Y 2 o 3 :Fe 2 o 3 =0.4:0.1:2.5:5 Weigh 500g, place the weighed raw materials in an agate mortar and grind them thoroughly for 3 hours to obtain a mixed powder raw material; place the mixed powder raw material at a temperature of 1400°C Pre-fired for 12 hours, then ground for 2 hours to obtain YIG polycrystalline material;

[0045] (2) Add flux: add PbO-B in the YIG polycrystalline material that obtains in step (1) 2 o 3 Composite flux, wherein the mass ratio is YIG polycrystalline material: Fe2O3: PbO: B2O3 = 1.56:5.02:91.29:2.13, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com