Axial clearance adjusting device

A technology for adjusting device and axial clearance, which is applied in shaft installation, bearing assembly, shaft, etc. It can solve the problems of damaging the dimensional accuracy of bearing holes, large axial restraint force, and affecting installation accuracy, so as to achieve a wide range of use and improve control Accuracy and the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

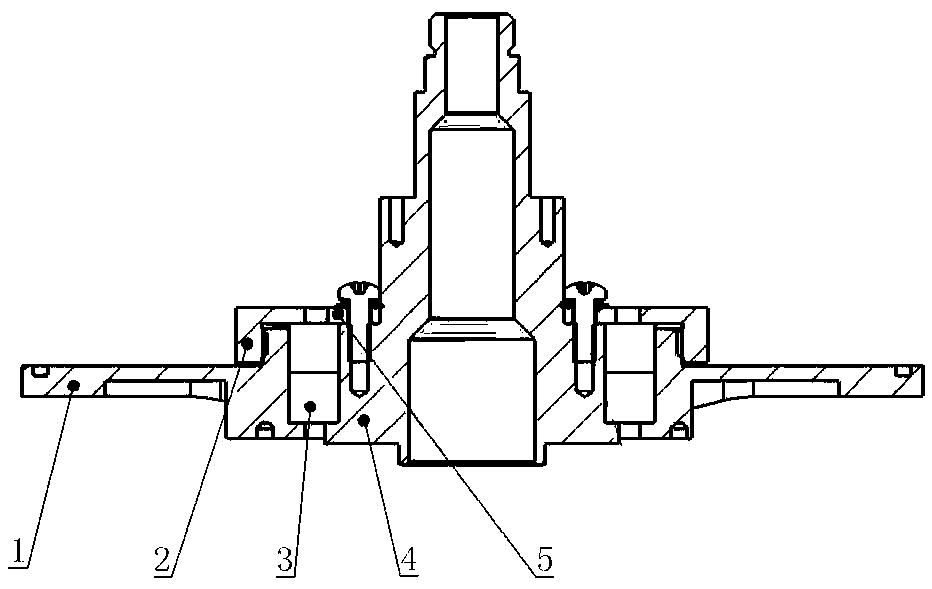

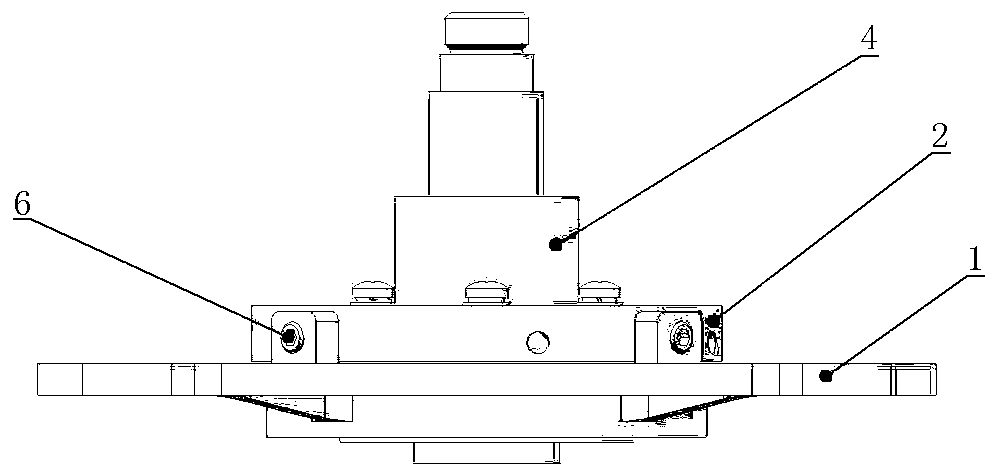

[0020] In this example, if figure 1 and figure 2 The axial gap adjustment device shown includes a first bearing seat 1, a first bearing thread pressure ring 2, an angular contact bearing 3, a vertical shaft 4, an inner gland 5 and a flat end set screw 6; an angular contact bearing 3 The inner ring of the inner ring is in contact with the vertical shaft 4, the inner gland 5 is fixed on the vertical shaft 4 by a combination screw, the outer ring of the angular contact bearing 3 is in contact with the inner hole of the first bearing seat 1, and the threaded pressure ring of the first bearing 2 Screw in the angular contact bearing 3.

[0021] In order to accurately adjust the clearance on the bearing shaft, the first bearing threaded pressure ring 2 adopts fine thread; in order to obtain a suitable preload, it is necessary to adjust the clearance while detecting the starting friction torque; further to prevent the first bearing threaded pressure ring from 2 Loosen, and lock the...

Embodiment 2

[0024] Further, in order to better adjust the bearing clearance, in figure 1 and figure 2 Add a deep groove ball bearing on the basis of the "2+1" bearing matching structure, that is, image 3 As shown in the axial clearance adjusting device, after being installed according to Embodiment 1, put the deep groove ball bearing 9 into the second bearing seat 7, and then put it into the vertical shaft 4 together. The outer diameter of the deep groove ball bearing 9 is the same as The inner diameter of the second bearing seat 7 is matched, and the bearing gland 8 is fixedly connected with the second bearing seat 7 with a combination screw, and the inner diameter of the deep groove ball bearing 9 is matched with the outer diameter of the vertical shaft 4, and the nut 10 is used to limit the position; here, The nut 10 can also adopt a gland-fixed structural form, which is similar to the installation method of the inner gland 5; this structural form can fully reflect the stepless adju...

Embodiment 3

[0026] In the case of satisfying the height space of Example 1 but not satisfying Example 2, another solution is proposed: in image 3 Replace a pair of angular contact bearings 3 with deep groove ball bearings 9 on the basis of Figure 4 Shown is an axial clearance adjustment device.

[0027] An axial gap adjustment device, the inner ring of the deep groove ball bearing 9 is in contact with the vertical shaft 4, the inner gland 5 is fixed on the vertical shaft 4 through a combination screw, and the outer ring of the deep groove ball bearing 9 is in contact with the first bearing seat The inner hole of 1 is matched and contacted, the outer gland 11 locks the bearing by screws, the deep groove ball bearing 9 is put into the second bearing seat 7, and then put into the vertical shaft 4 together, the inner diameter of the deep groove ball bearing 9 is consistent with the vertical shaft 4 Cooperate with the outer diameter of the outer diameter, use the nut 10 to limit the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com