Coil-type equipment oil leakage plugging device and method

A plugging device and equipment technology, applied in the direction of mechanical equipment, engine sealing, engine components, etc., can solve the problems of reduced plugging capacity, increased equipment operation and maintenance costs, and reduced plugging success rate to meet the speed and sealing requirements High demand, improve long-term effectiveness, improve the effect of plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

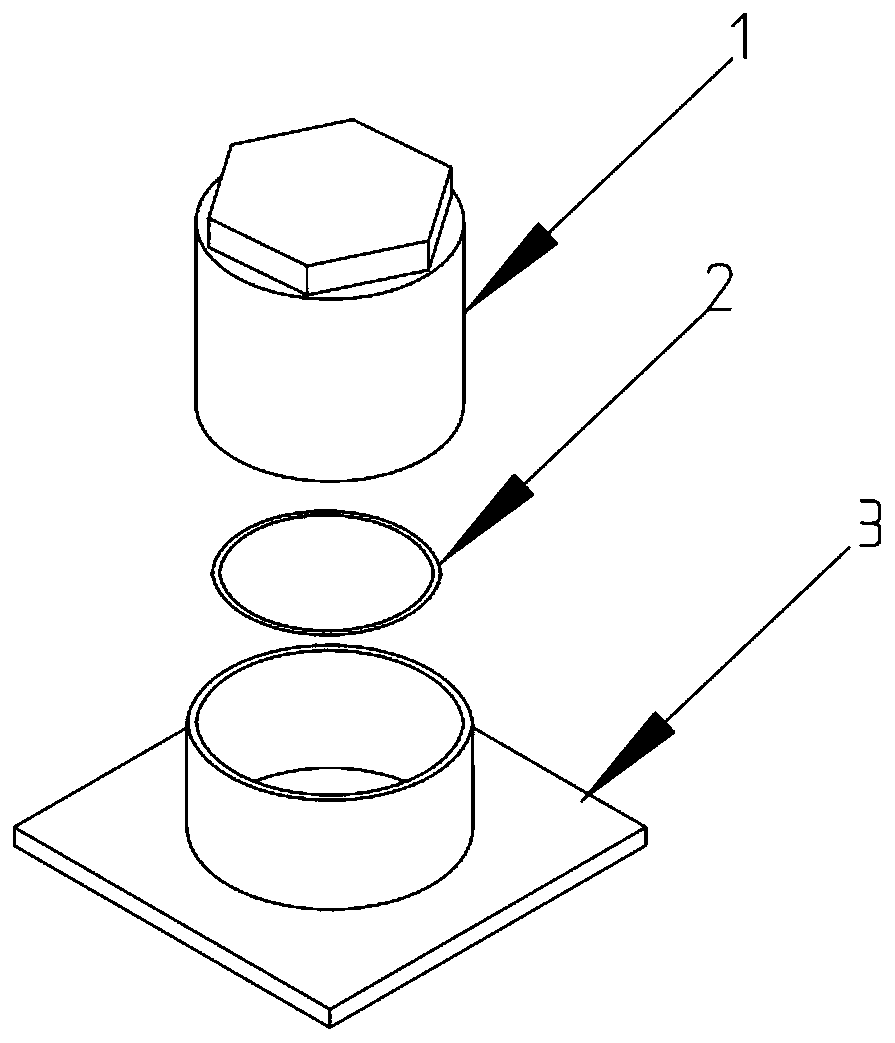

[0035] In a typical implementation of the present application, such as figure 1 As shown, a device and method for oil leakage plugging of coil type equipment applied to the outer wall of a planar workpiece are proposed.

[0036]The blocking device mainly includes three parts, a docking base, a gasket and a fastener. In this embodiment, the docking base is a bonding base 3 provided with a through hole and a docking cylinder communicating with the through hole. The bonding base is a planar plate, which is used to fit the planar outer wall of the workpiece to be blocked. The butt joint is arranged coaxially with the through hole and fixed on the joint base through the end. The joint joint and the fastener To cooperate, an annular gasket is provided between the fastener and the outer wall of the workpiece to be blocked. In this embodiment, the fastener is selected from a cylindrical fastening bolt cap 1 with one end closed, which has a A cavity, after cooperating with the bonding...

Embodiment 2

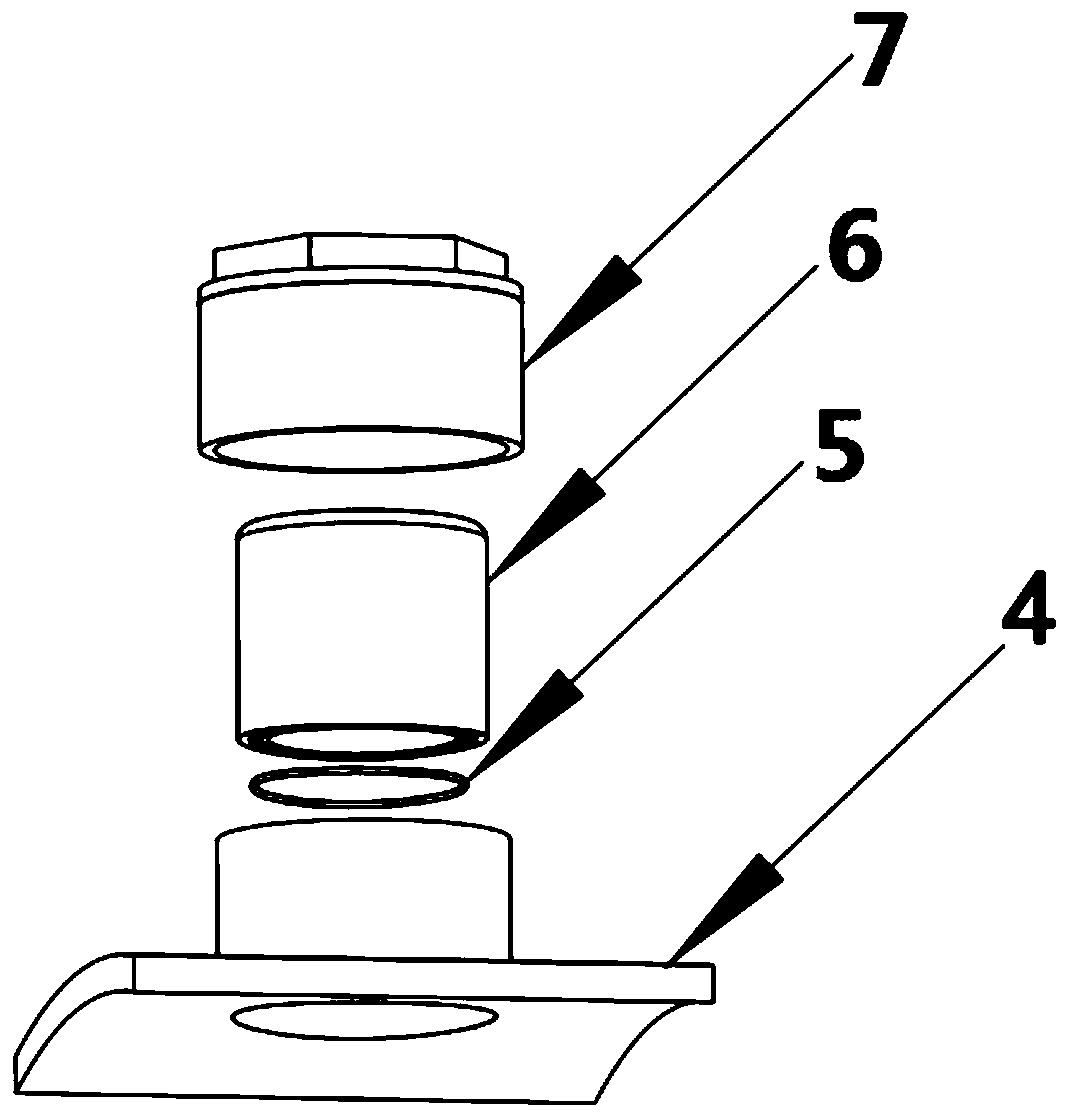

[0048] In a typical implementation of the present application, such as figure 2 As shown, a device and method for oil leakage plugging of coil type equipment applied to the outer wall of arc-shaped workpieces is proposed.

[0049] The difference from Embodiment 1 is that in this embodiment, the bonding base 4 is an arc-shaped plate, and while the sealing ring 5 is arranged between the fastening bolt cap 7 and the outer wall of the workpiece, a sleeve 6 is also added as a The middle fastener, the fastening bolt cap is a cylindrical structure with one end blocked, and a sleeve is fitted inside, one end of the sleeve contacts the fastening bolt cap, and the other end fits the sealing ring, and the fastening bolt cap Press the sealing ring through the sleeve to make the sealing ring close to the outer wall of the workpiece;

[0050] Further, one end of the sleeve fitting the gasket is an arc-shaped structure matching the outer wall of the workpiece to be sealed, which is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com