Surrounding rock mechanical parameter automatic testing system and method suitable for TBM

An automatic testing system and technology of mechanical parameters, applied in the direction of applying stable tension/pressure to test material strength, soil material testing, testing wear resistance, etc., can solve problems that affect tunneling, high test accuracy, and long time consumption, and achieve Strong timeliness, high degree of automation, guaranteed accuracy and authoritative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

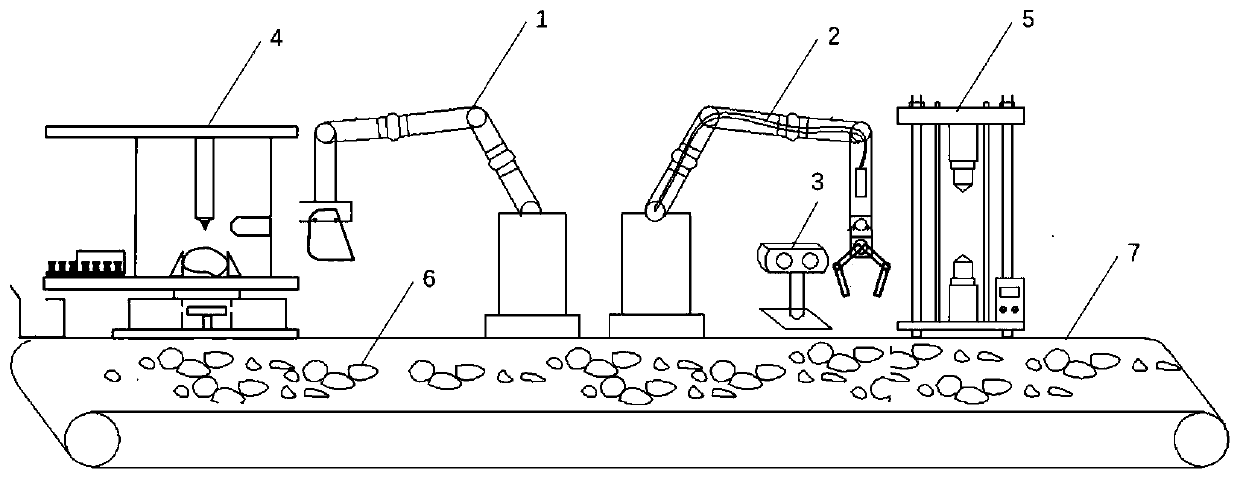

[0047] In one or more embodiments, an automatic testing system for surrounding rock mechanical parameters suitable for TBM is disclosed, referring to figure 1 , including: collection device 1, mechanical gripper 2, high-pressure nozzle 9, infrared depth binocular camera 3, compressive strength test bench 5, rock abrasiveness test bench 4.

[0048]During the TBM construction process, the rock slag 6 produced by the excavation of the TBM cutter head is transported out of the tunnel by the belt conveyor 7 . A collection device 1 , a mechanical gripper 2 , an infrared depth binocular camera 3 and a rock abrasiveness test bench 4 are arranged on one side of the conveying direction of the belt conveyor 7 .

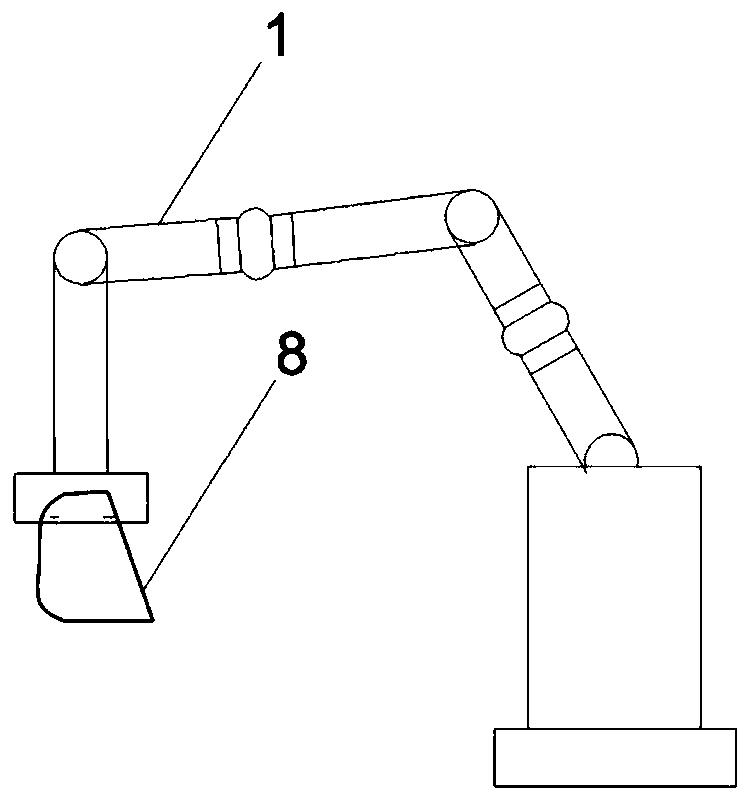

[0049] Among them, refer to figure 2 , The collecting device 1 is composed of a six-degree-of-freedom mechanical arm and a bucket 8, and can be placed beside the TBM belt conveyor 7. The robotic arm can translate in three mutually perpendicular coordinate systems of X-axis, Y...

Embodiment 2

[0069] In this embodiment, on the basis of Example 1, a compressive strength testing platform is added, referring to Figure 7 , The compressive strength test platform is composed of a platform support, an electro-hydraulic jack 19, two loading cones 18, and a program-controlled host 20. The platform bracket is supported by the upper platform, the test bench base, and the upper platform and the base with four steel columns.

[0070] The electro-hydraulic jack 19 drives two opposite loading cones 18 to move in opposite directions, and after the two loading cones 18 contact the rock slag, the current pressure of the rock slag is automatically recorded by the hydraulic sensor, and transmitted to the program-controlled host 20 . The two loading cones 18 are two movable loading cones 18, one up and one down, which can be displaced relative to each other. The tips of the two loading cones 18 are located on the same vertical line relative to the ground reference system. The program-...

Embodiment 3

[0073] On the basis of Embodiment 1 and Embodiment 2, this embodiment discloses a method for automatically testing surrounding rock mechanical parameters suitable for TBM, including the following working steps:

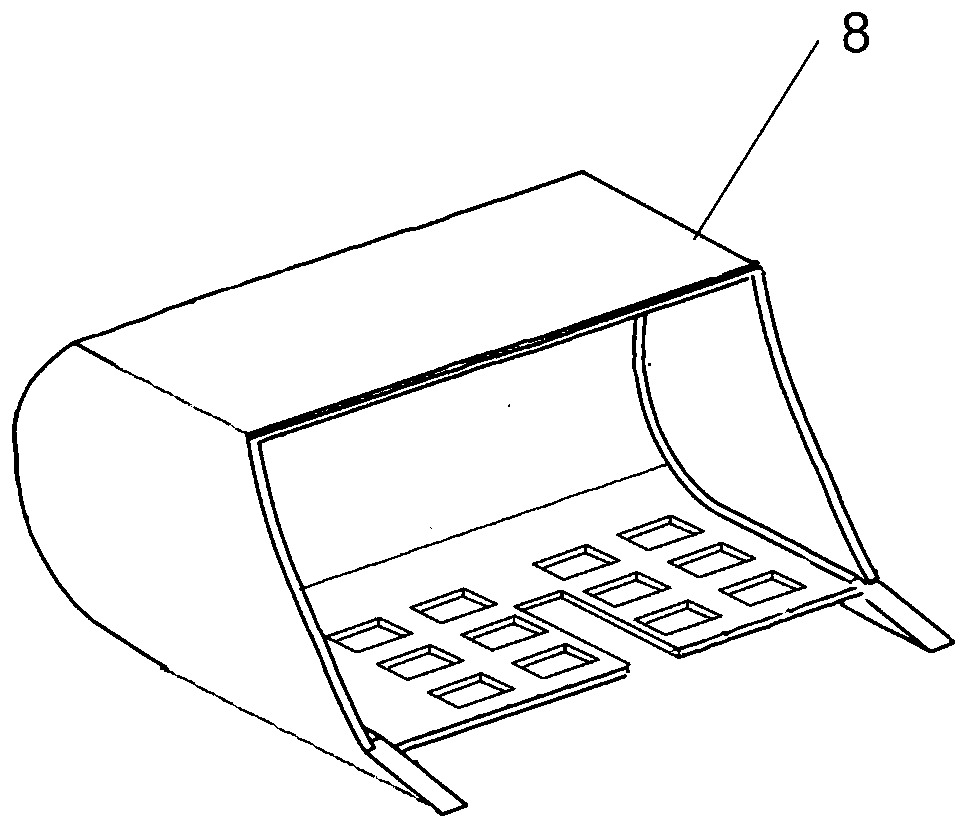

[0074] Collecting device 1 manipulator handles bucket 8 to contact the belt conveyor surface, stays for a short time on belt conveyor 7, and shovels out rock slag that moves on some belt conveyors 7. Since the shoveled rock slag will have a large number of rock slag fragments less than 30mm that do not meet the requirements of the compressive strength test, the bucket 8 is folded with the gap in the center of the bucket as the axis, so that the bucket surface is inclined, and the rock slag with a particle size of less than 30mm The slag fragments pass through the 30mm gap reserved in the middle of the bucket, while the rock slag with a particle size greater than 30mm is retained in the bucket 8 .

[0075] Specifically, the mechanical arm of the collecting device 1 fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com