Micro-channel vapor chamber with recess structure

A micro-channel and vapor chamber technology, which is applied to electrical components, electric solid devices, circuits, etc., can solve the problem of increased heat transfer resistance of micro-channel condensing plates, preventing direct contact between steam and condensing plates, and the overall heat dissipation performance of the vapor chamber To achieve the effects of superior anti-drying characteristics, improved average temperature and heat dissipation performance, and improved steam convective heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

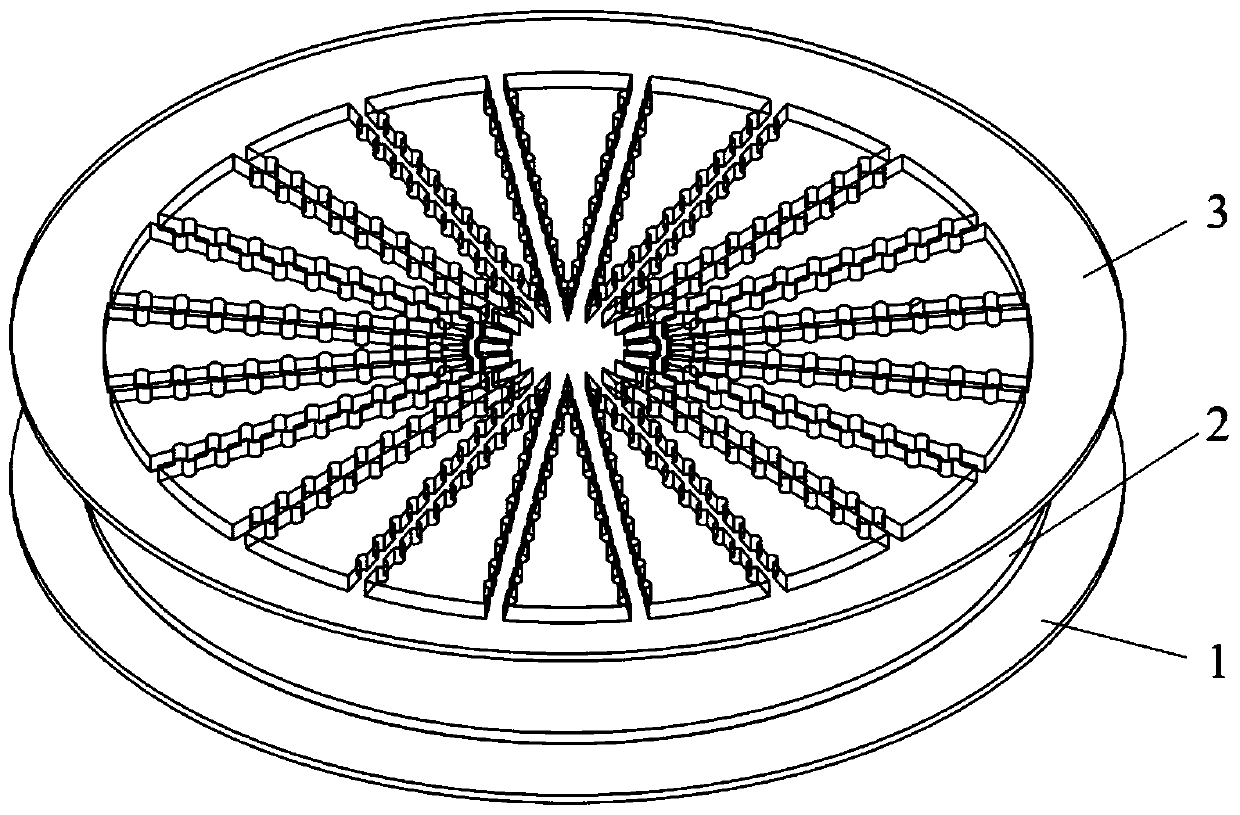

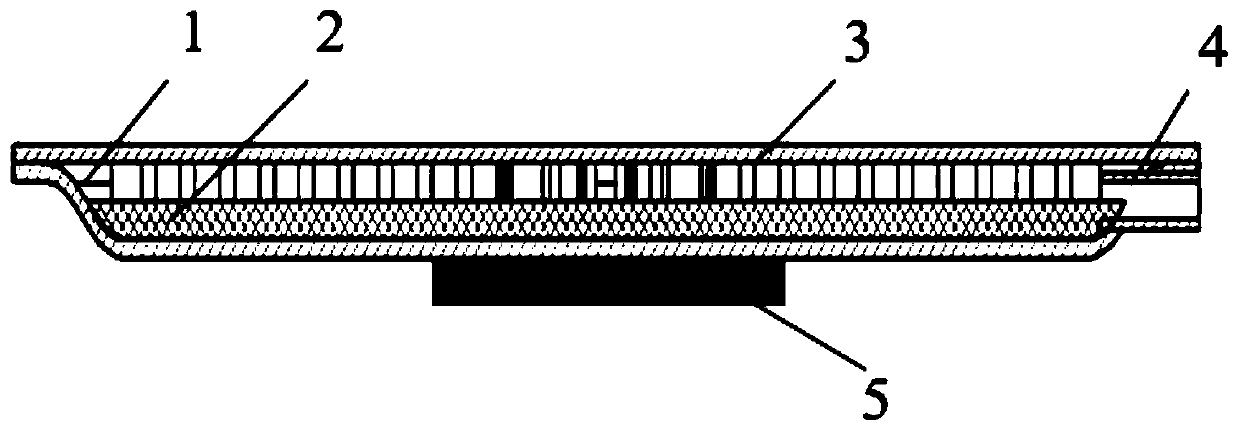

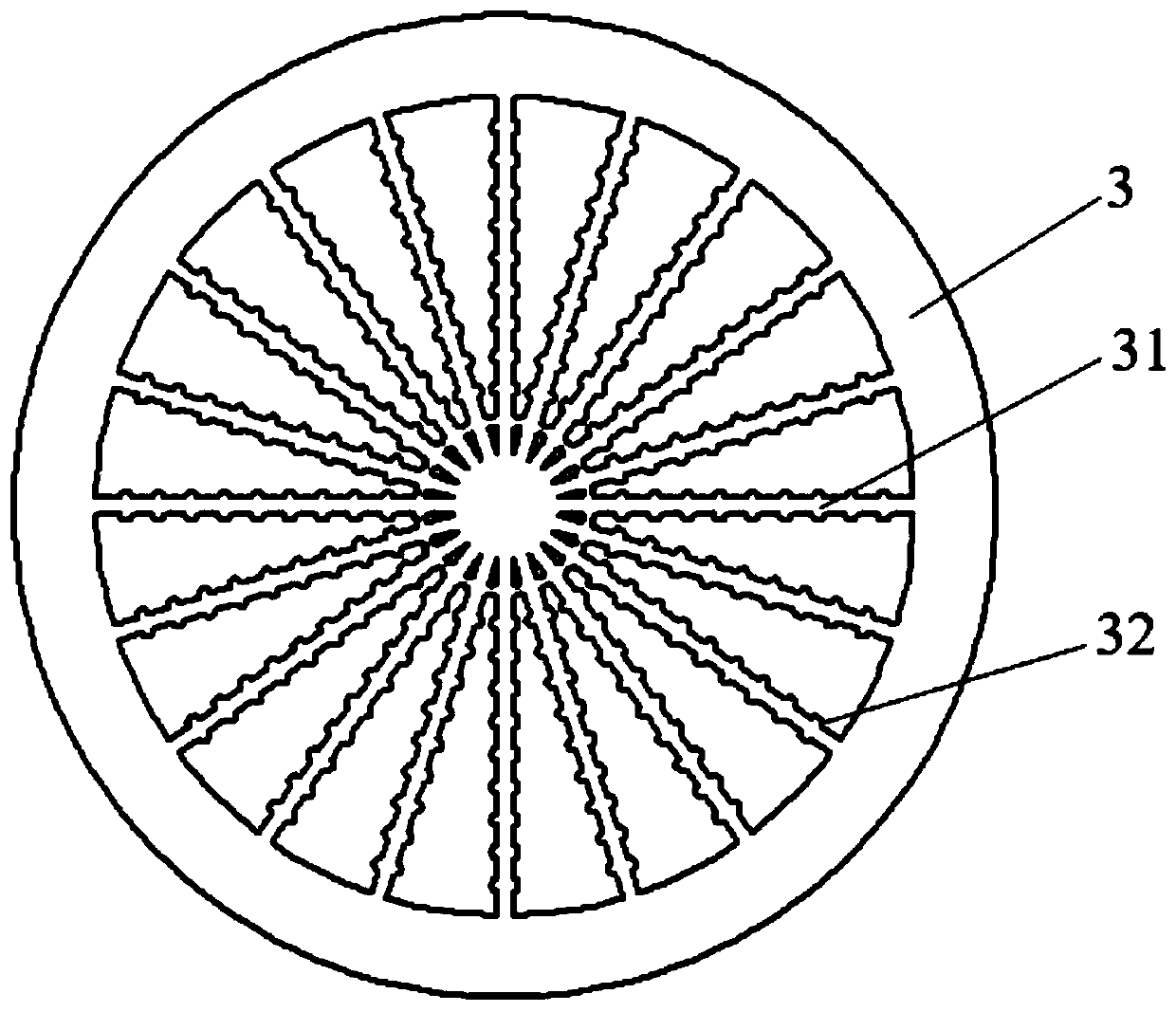

[0033] like Figure 1-Figure 3 As shown, a microchannel vapor chamber with a cavity structure includes a base plate 1, a capillary core 2 and a cover plate 3. A cavity is provided on the inner surface of the base plate, and the capillary core 2 is embedded in the cavity of the base plate to form a uniform vapor chamber. Evaporating end of the hot plate. In this embodiment, both the cover plate and the bottom plate are circular, and the inner surface of the cover plate is processed with a microchannel structure 31 in a circumferential array. Diverge toward the edge and arrange evenly. In this embodiment, there are 20 microchannels, and recess structures 32 are processed on both sides of the inner surface of the microchannels.

[0034] like image 3 As shown, in the present embodiment, the recess structure is made of a plurality of semicircular recesses 32, and a plurality of semicircular recesses are symmetrically distributed on both sides of the microchannel, and the diamete...

Embodiment 2

[0040] see Figure 4 and Figure 5 , The difference between this embodiment and Embodiment 1 is that the shape of the cover plate and the bottom plate is square, the microchannel array on the cover plate is a parallel rectangular straight microchannel array, and the cavity structure is a rectangular cavity.

[0041] Other parameter settings and processing methods of this embodiment are the same as those of Embodiment 1.

[0042] Image 6 Among them, Temperature represents temperature, and 340, 342, 344, etc. represent changes in temperature. Figure 7 Among them, Velocity represents the flow velocity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com