Manufacturing method of high-fidelity blue-light-free solar spectrum LED and LED

A solar spectrum, no blue light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced lighting comfort, low lighting comfort, and large thickness of LEDs, to improve shaping and drying effects, and improve lighting. Comfortable, improved luminous uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

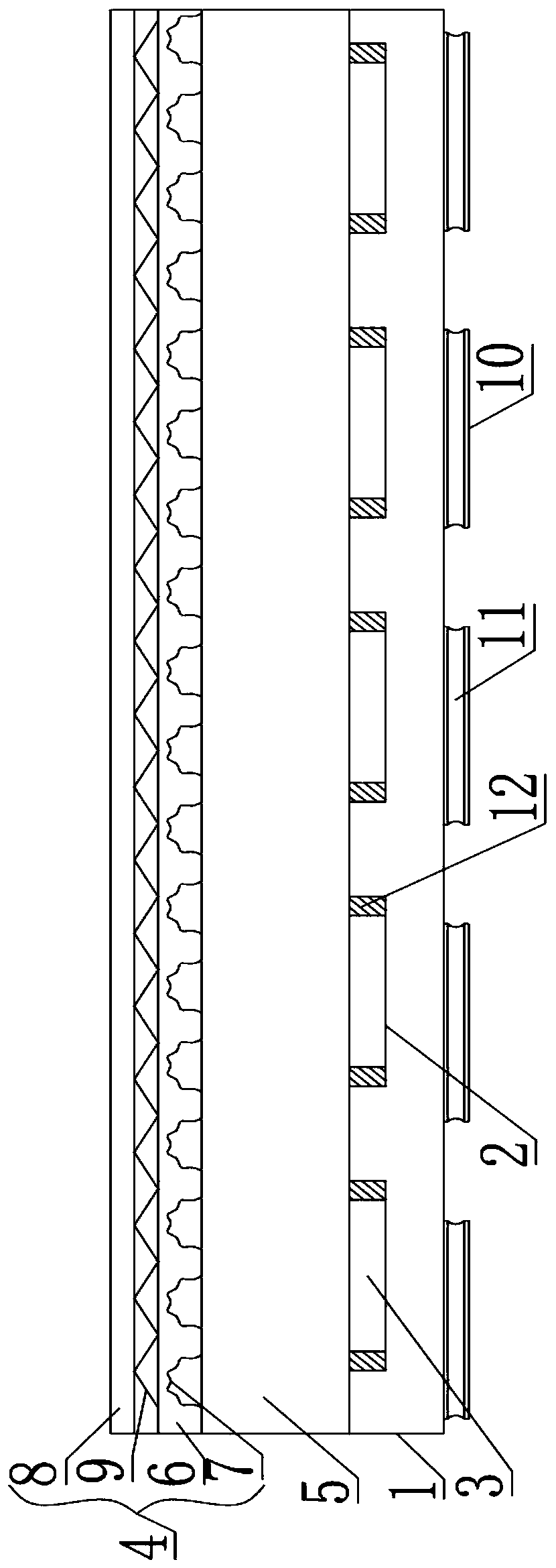

[0020] Example 1. The preparation method of the high-fidelity blue-light-free solar spectrum LED is characterized in that it comprises the following steps:

[0021] a. Phosphor powder glue is prepared, according to the weight ratio: 1.88 parts of blue-green phosphor, 42.6 parts of yellow-green phosphor, 0 part of yellow phosphor, 9.062 parts of orange-red phosphor and 0 part of red phosphor to obtain a mixed phosphor; Then mix according to the weight ratio of 10.5 parts of glue A, 105 parts of glue B and 1.2 parts of anti-sedimentation powder to obtain the mixed glue; finally perform supercritical mixing according to the weight ratio of 1 part of mixed phosphor powder and 1 part of mixed glue, get product A;

[0022] b. Solid crystal, using solid crystal glue to fix the multi-chip on the installation base to obtain product B;

[0023] c. Apply fluorescent glue, use a high-speed rotating machine to drive product B to rotate at a high speed, and at the same time dispense produ...

Embodiment 2

[0028] Example 2. A method for preparing a high-fidelity blue-light-free solar spectrum LED, comprising the following steps:

[0029] a. Phosphor powder glue is prepared, according to the weight ratio: 5.04 parts of blue-green phosphor powder, 10.25 parts of yellow-green phosphor powder, 5.58 parts of yellow phosphor powder, 2.07 parts of orange-red phosphor powder and 0.204 part of red phosphor powder to obtain a mixed phosphor powder; Then mix 8.5 parts of glue A, 85 parts of glue B and 1 part of anti-sedimentation powder according to the weight ratio to obtain the mixed glue; finally perform supercritical mixing according to the weight ratio of 1 part of mixed phosphor powder and 1 part of mixed glue, get product A;

[0030] b. Solid crystal, using solid crystal glue to fix the multi-chip on the installation base to obtain product B;

[0031] c. Apply fluorescent glue, use a high-speed rotating machine to drive product B to rotate at a high speed, and at the same time dis...

Embodiment 3

[0036] Example 3. A method for preparing a high-fidelity blue-light-free solar spectrum LED, comprising the following steps:

[0037] a. Prepare fluorescent powder glue, according to the weight ratio: 1.5 to 6.5 parts of blue-green phosphor, 10 to 43 parts of yellow-green phosphor, 0 to 6.5 parts of yellow phosphor, and 1.5 to 10 parts of orange-red phosphor and 0-0.35 parts of red phosphor powder to obtain mixed phosphor powder; then mix 8-11 parts of glue A, 80-110 parts of glue B and 1-1.5 parts of anti-sedimentation powder according to the weight ratio, Obtain the mixed glue; finally carry out supercritical mixing according to the weight ratio of 1 part of mixed phosphor powder and 1 part of mixed glue to obtain product A;

[0038] b. Solid crystal, using solid crystal glue to fix the multi-chip on the installation base to obtain product B;

[0039] c. Apply fluorescent glue, use a high-speed rotating machine to drive product B to rotate at a high speed, and at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com