Fuel cell bipolar plate, manufacturing method and used equipment thereof

A fuel cell and bipolar plate technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of long time consumption, excessive time, and low efficiency, and achieve the effects of increasing contact area, good electrical conductivity, and increasing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

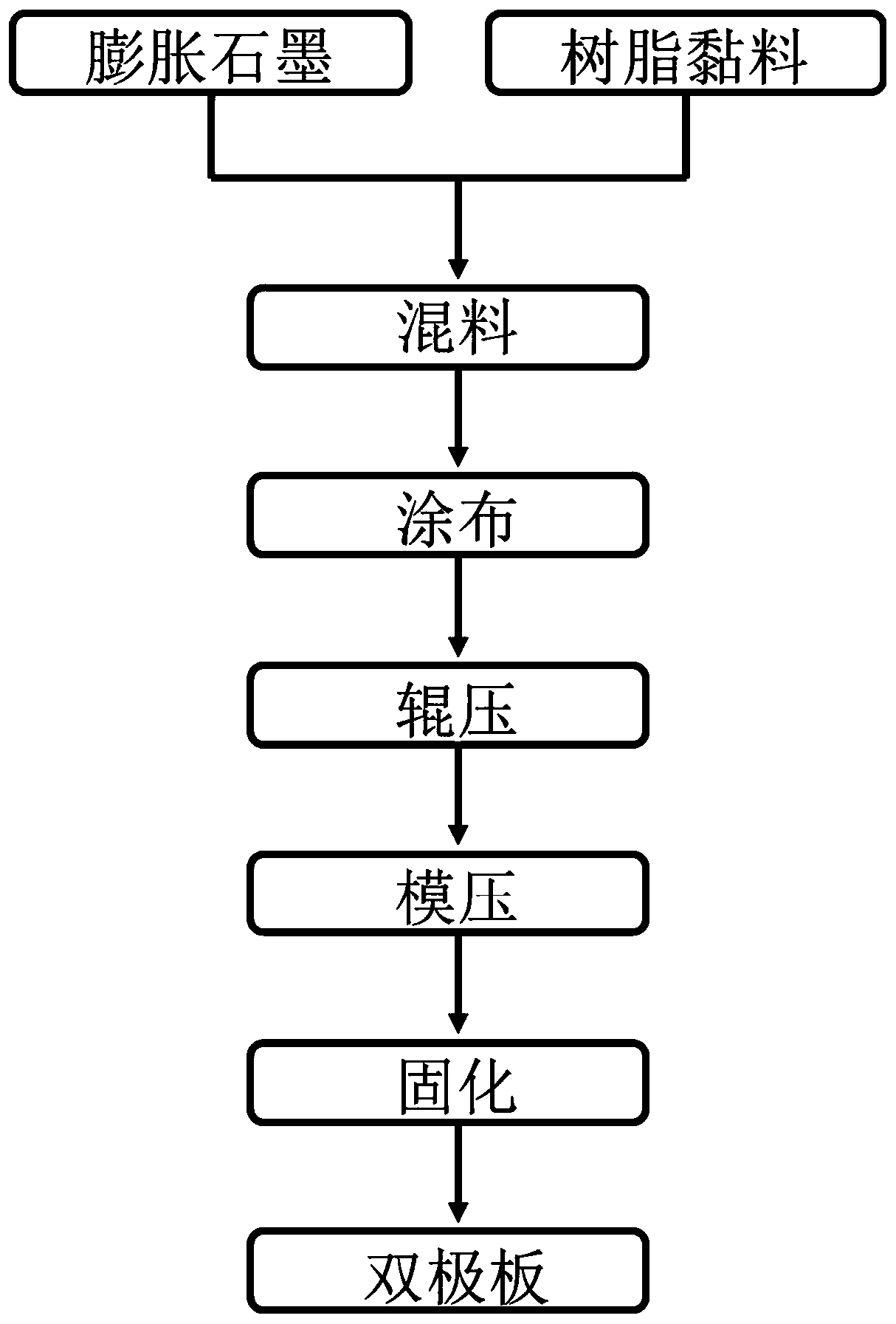

[0030] refer to figure 1 , the first embodiment of the present invention provides a method for preparing a fuel cell bipolar plate, comprising the following steps:

[0031] (1) Mixing the graphite material and the resin binder evenly to obtain a mixed slurry;

[0032] (2) coating the mixed slurry on a metal foil, pressing to obtain a pre-pressed plate, and then molding the pre-pressed plate to obtain a molded plate, at least one side of the molded plate has a flow channel;

[0033] (3) separating the molded plate from the mold to obtain a molded bipolar plate;

[0034] (4) Solidifying and cooling the formed bipolar plate to obtain the fuel cell bipolar plate.

[0035] The preparation method provided by the embodiment of the present invention fully ensures that the graphite material and the resin binder are mixed evenly through a reasonable graphite material / resin slurry ratio, and fully mixes the resin binder evenly in the three-dimensional network structure of the graphite ...

Embodiment 1

[0056]In this embodiment, the continuous production of fuel cell bipolar plates is realized by adopting the manufacturing process of coating the metal foil surface with roll press molding. The specific steps are as follows:

[0057] 1) First mix the expanded graphite and the resin binder in a mass ratio of 1:1, and stir evenly in a mixer to form a mixed slurry;

[0058] 2) Set the copper foil between the active steel roller and the active silica gel roller of the coating machine, so that the mixed slurry is evenly coated on the copper foil;

[0059] 3) Copper foil with mixed slurry is rolled by a roller press to make a thickness of 4mm and a density of 0.6g / cm 3 the pre-pressed plate;

[0060] 4) The pre-pressed plate in step 3) is molded again through a molding machine under the condition of a pressure of 80MPa and a temperature of 300°C to make a thickness of 3.0mm and a density of 0.5g / cm 3 , and molded plates with corresponding runners on both sides;

[0061] 5) Separa...

Embodiment 2

[0064] In this embodiment, the continuous production of fuel cell bipolar plates is realized by adopting the manufacturing process of coating the metal foil surface with roll press molding. The specific steps are as follows:

[0065] 1) First mix the expanded graphite and the resin binder in a mass ratio of 1:1, and stir evenly in a mixer to form a mixed slurry;

[0066] 2) Set the copper foil between the active steel roller and the active silica gel roller of the coating machine, so that the mixed slurry is evenly coated on the copper foil;

[0067] 3) Copper foil with mixed slurry is rolled by a roller press to make a thickness of 3.5mm and a density of 0.7g / cm 3 the pre-pressed plate;

[0068] 4) The pre-pressed plate in step 3) is molded again through a molding machine under the condition of a pressure of 60MPa and a temperature of 300°C to make a thickness of 2.0mm and a density of 1.0g / cm 3 , and molded plates with corresponding runners on both sides;

[0069] 5) Sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com