Composite heat dissipation water-cooling-free laser

A laser, no water cooling technology, applied in the field of lasers, can solve the problems of difficult to grasp the temperature control accuracy, heavy weight, short service life, etc., to achieve the effect of satisfying the portable performance, high degree of automation, and low heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

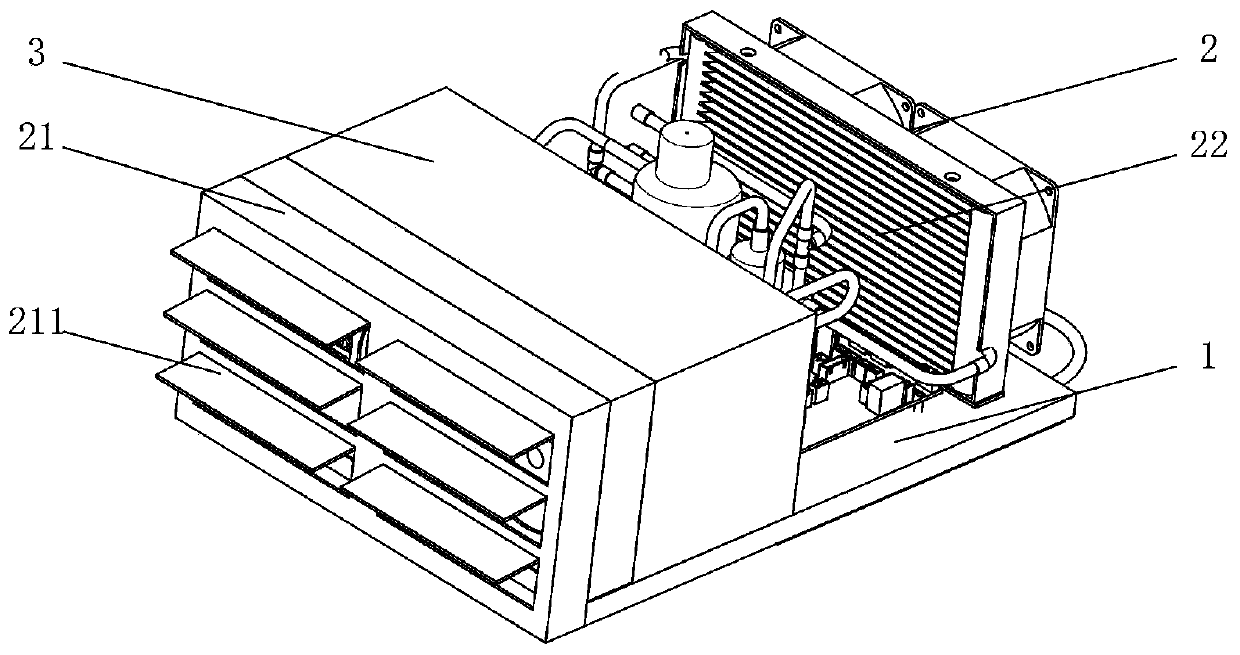

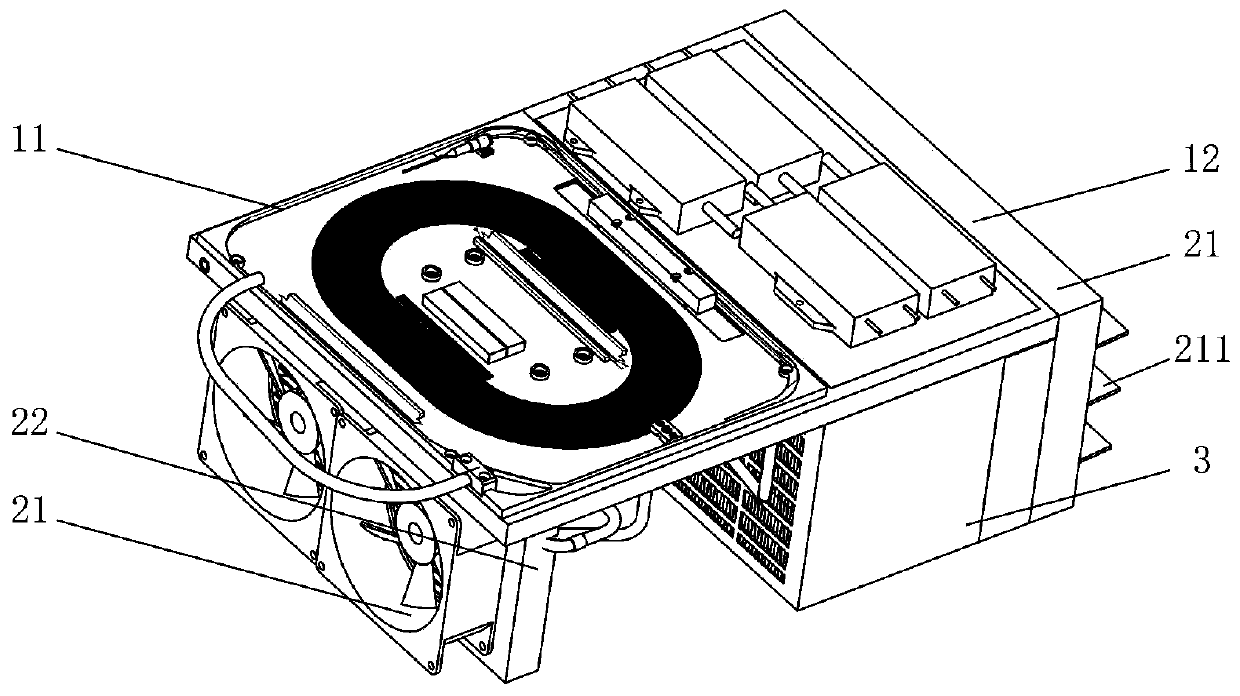

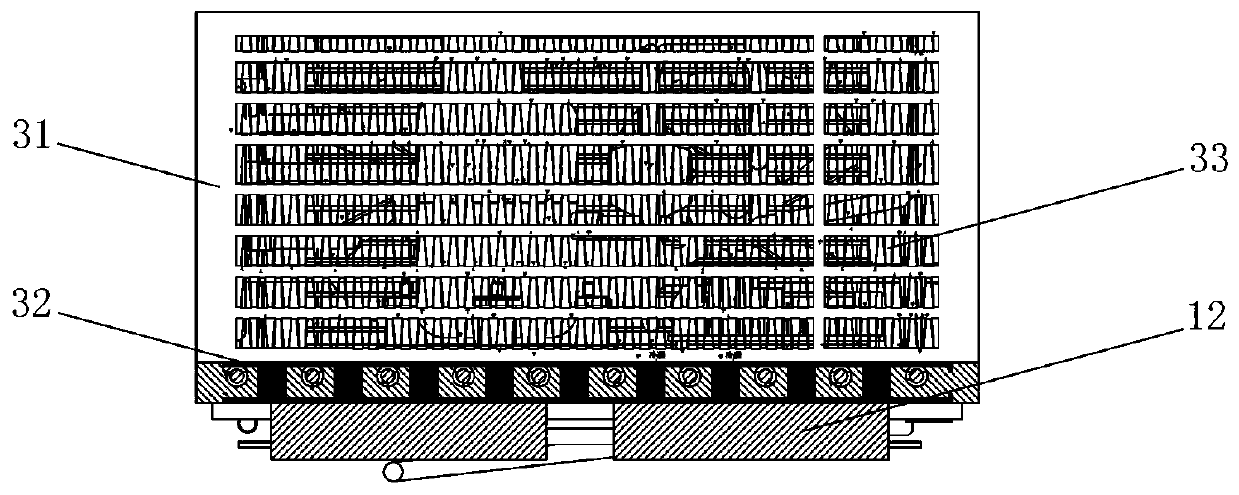

[0029] Such as figure 1 and figure 2 As shown, the composite heat dissipation non-water-cooled laser of this embodiment includes an optical system 1 and a heat dissipation device 2, and also includes a phase change heat dissipation system 3, and the heat dissipation device 2 can provide a cold source for the phase change heat dissipation system 3; the phase change heat dissipation system 3 includes The housing 31 is provided with a liquid pool 32 inside the housing 31 , and the bottom of the liquid pool 32 is close to the optical system 1 ; the housing 31 is also provided with a phase change material. When working, the optical system 1 will dissipate a large amount of heat, and the originally liquid phase-change material contained in the liquid pool 32 absorbs the heat dissipated by the optical system 1 and evaporates; since the cooling device 2 provides low temperature, the evaporated phase The variable material is liquefied after condensation, and returns to the liquid poo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com