Bean paste wrapping machine, and bean paste wrap manufacturing method

A manufacturing method and technology of a stuffing machine, which are applied in the directions of dough extruders, food coating, dough cutting machines, etc., can solve the problems of restricting the shape of formed cakes, easy to increase investment, unsuitable for making cakes, etc. The effect of low cost, wide versatility and simple structure of the device itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific example of the form for implementing the stuffing machine and the stuffed roll manufacturing method of the present invention will be described in detail below with reference to the drawings.

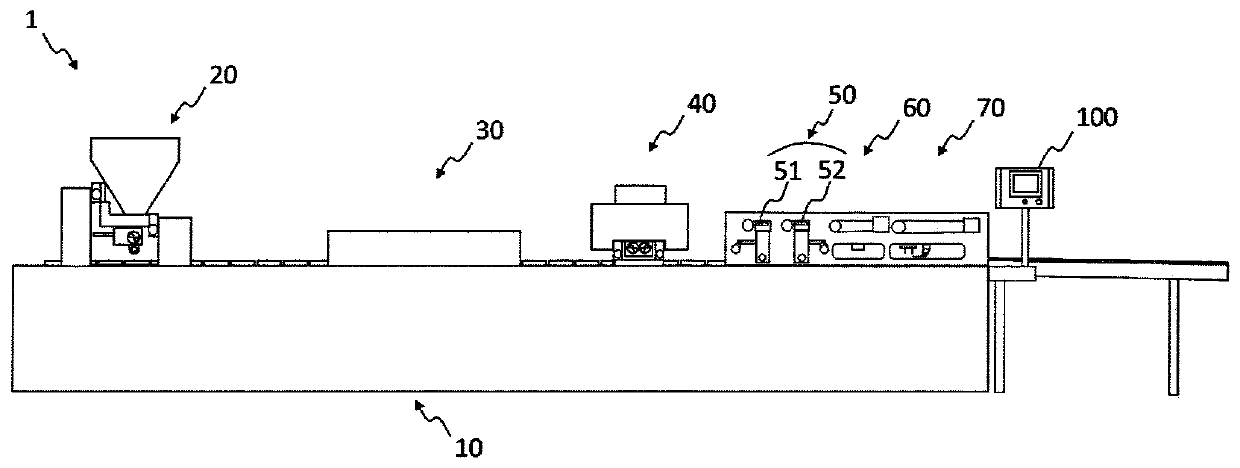

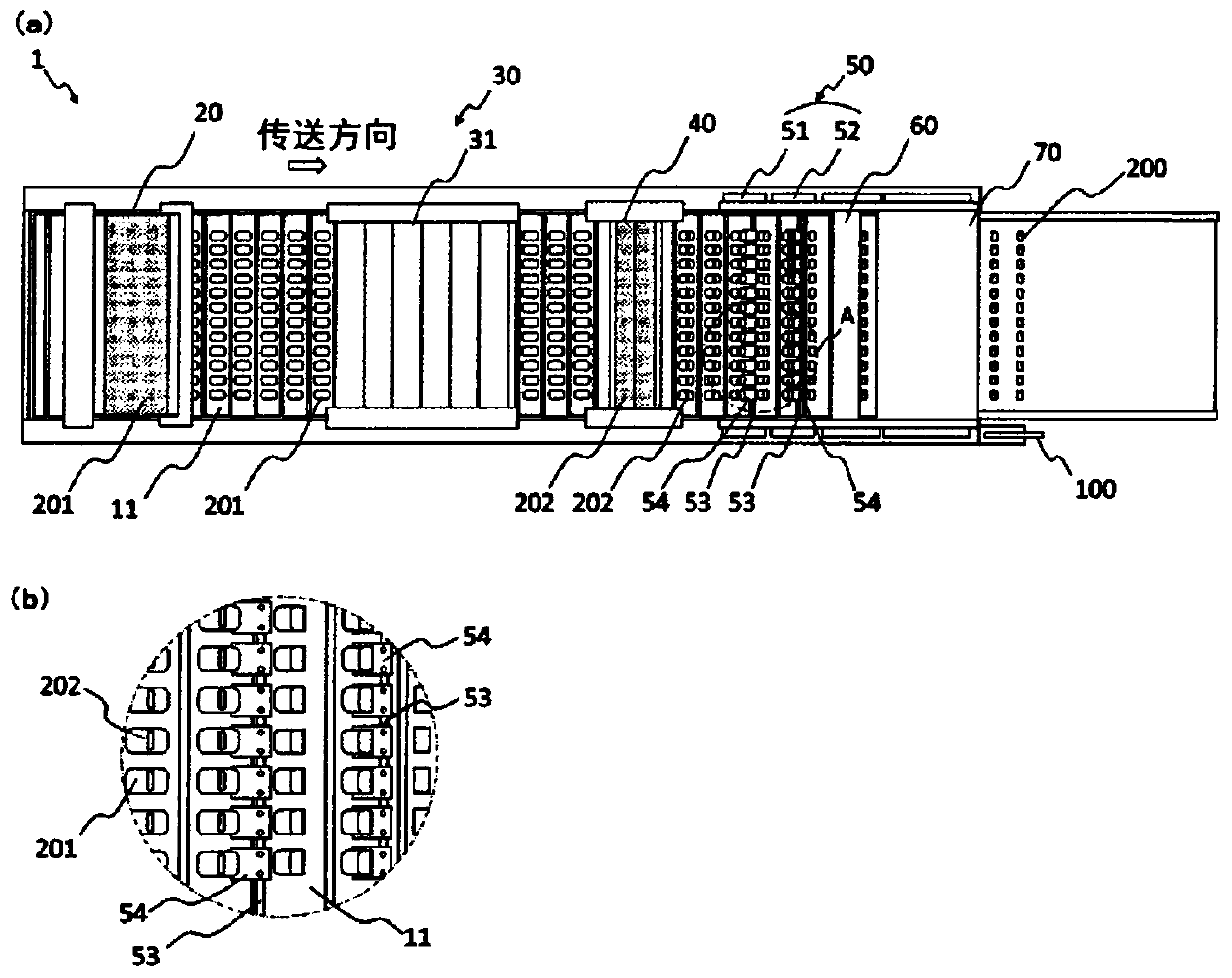

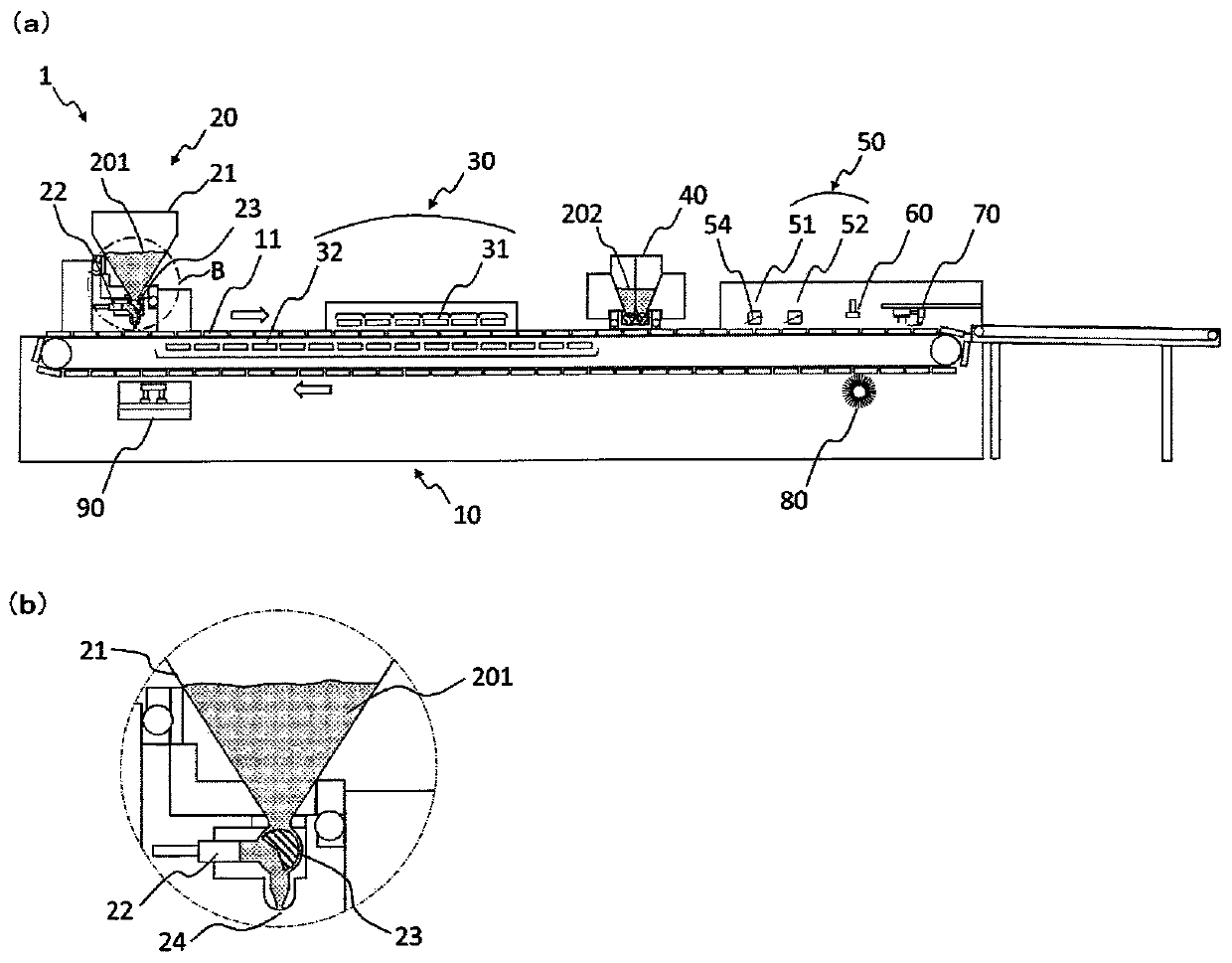

[0029] figure 1 It is a schematic diagram showing the overall structure of a stuffing rolling machine according to an embodiment of the present invention, figure 2 yes means figure 1 The overall structure diagram of the stuffing machine. figure 2 (a) is the overall composition diagram, figure 2 (b) is a detailed view of part A. also, image 3 Yes figure 1 A schematic diagram of the internal section of the stuffing machine, image 3 (a) is the overall composition diagram, image 3 (b) is a detailed view of part B.

[0030] refer to Figure 1 ~ Figure 3 , the stuffing machine 1 of the embodiment of the present invention has: a conveying device 10, which is installed in a plurality of parallel ways to transfer the baking plates 11 of the stuffed dough, and move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com