Packaging assembly line for automatic forming fillers of cartons

A packaging line and automatic forming technology, applied in packaging and other directions, can solve the problems of easy spillage of materials, large mechanical loss, long production line, etc., to achieve stable and smooth coordination, improve packaging efficiency, and improve operating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

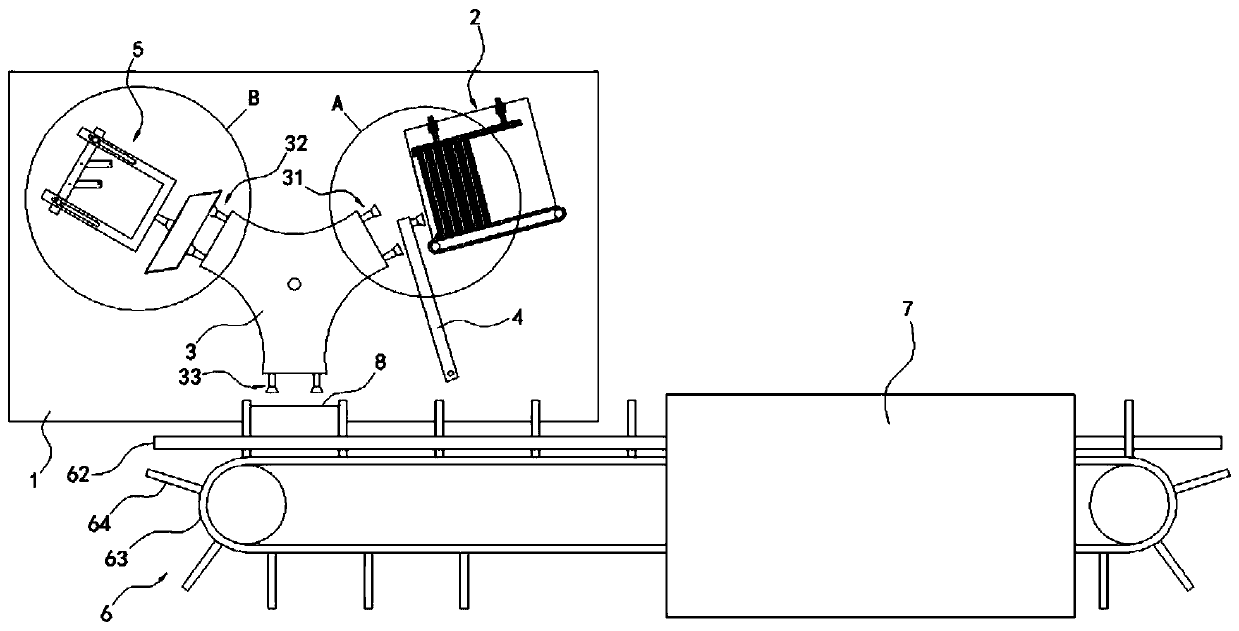

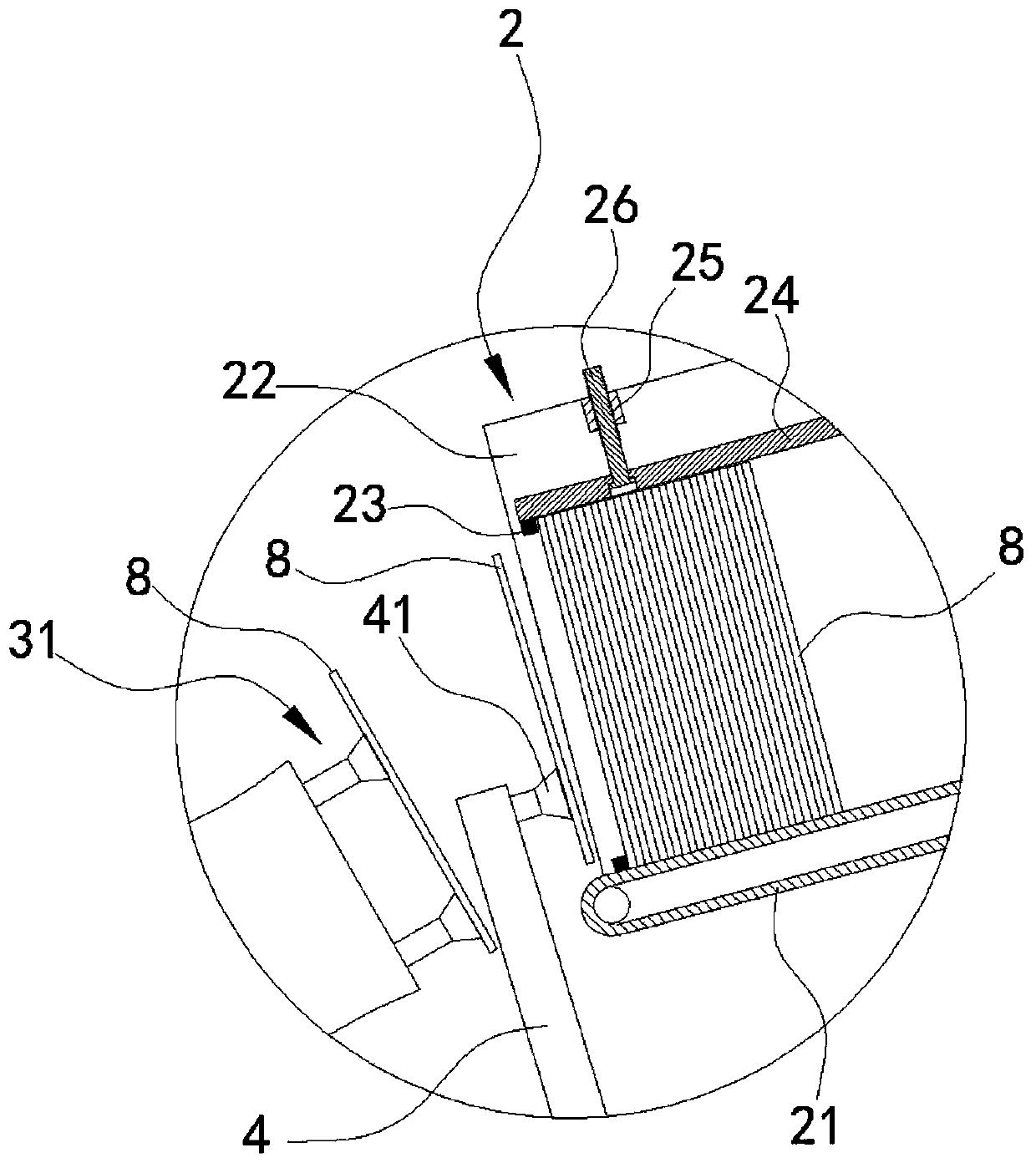

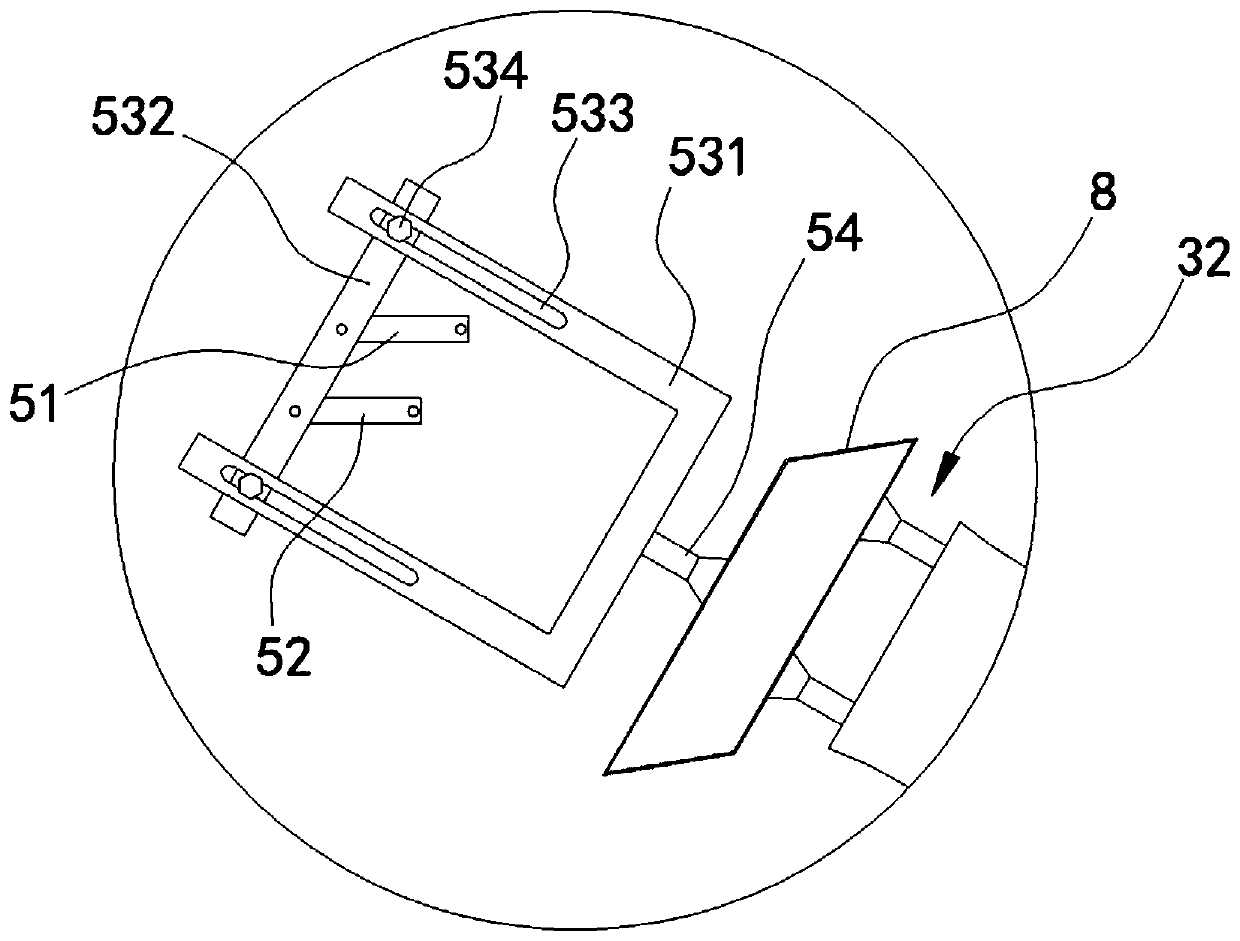

[0034] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine figure 1 - Image 6 The accompanying drawings describe the present invention in further detail.

[0035] refer to figure 1 - Image 6 As shown, a packaging line for automatic filling of cartons, including a frame 1, a box storage tank 2, a turntable 3, a box take-out lever 4, a box opening mechanism 5, a packaging conveyor belt 6, and a filling mechanism 7.

[0036] The storage box slot 2 is obliquely fixed on the frame 1, so that the folded flat box body 8 in the storage box slot 2 accumulates at the lower end of the storage box slot 2, and the edge of the lower end of the storage box slot 2 is set Block 23 is arranged to stop box body 8 from falling.

[0037] The box storage tank 2 includes a storage box conveyor belt 21 and baffles 22 arranged on both sides of the storage box conveyor belt 21. The storage box conveyor belt 21 is conveyed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com