Method for in-situ synthesis of BiOI composite catalyst and product

A composite catalyst, in-situ synthesis technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor interface effect, low electron-hole separation rate, etc. Purity and crystallinity, beneficial effect on catalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

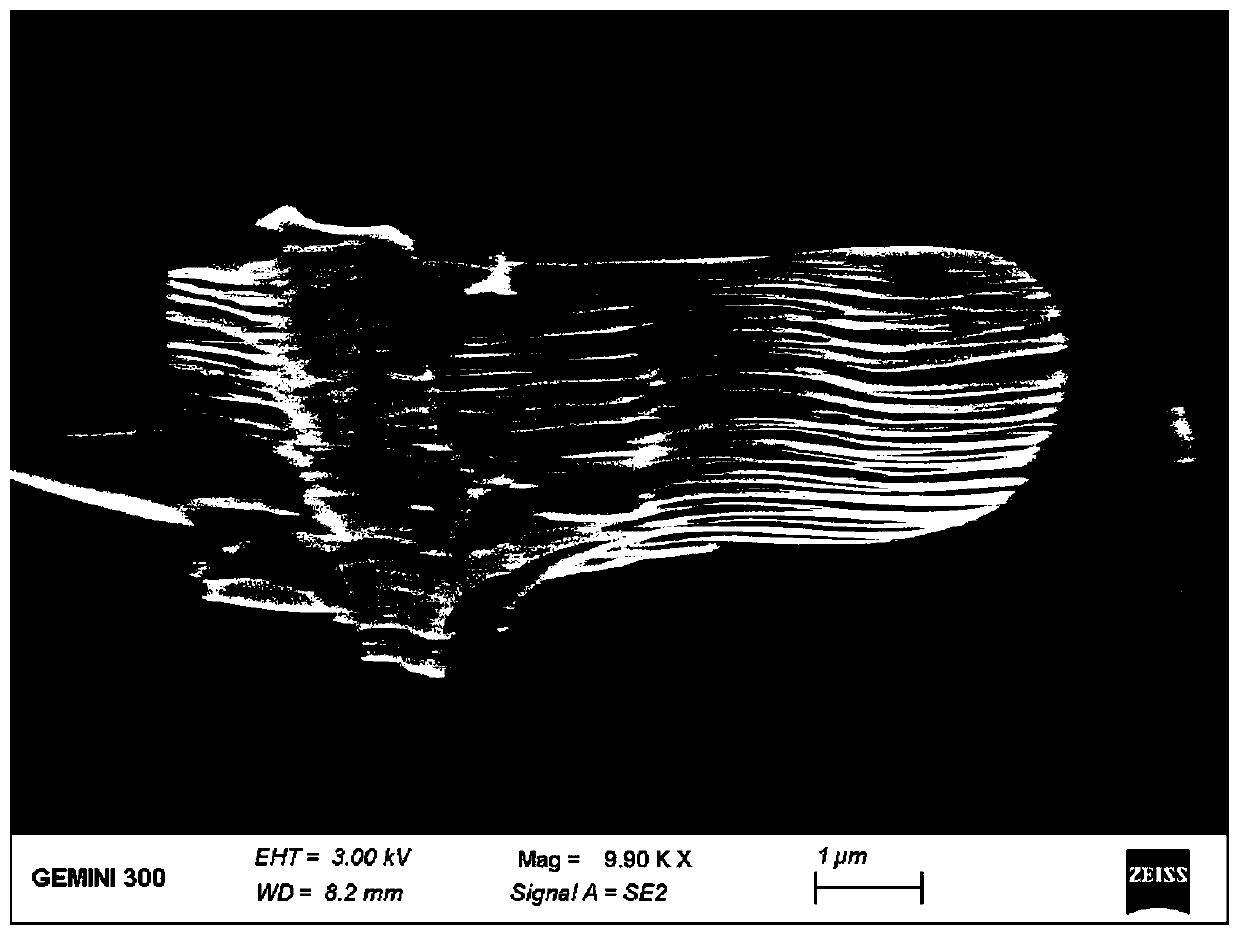

[0041] 1) 15g Ti 3 AlC 2 The -MAX phase ceramic powder was slowly added into 300 mL of HF solution with a mass concentration of 49%, and reacted with a magnetic stirrer for 36 hours under the condition of an oil bath at 50°C.

[0042] 2) After the reaction, wash the precipitate by centrifugation with deionized water until the pH of the supernatant is between 5 and 6, then wash the precipitate by centrifugation twice with absolute ethanol, and then vacuum-dry the obtained precipitate at 60°C for 24 hours , get Mxene-Ti 3 C 2 Material;

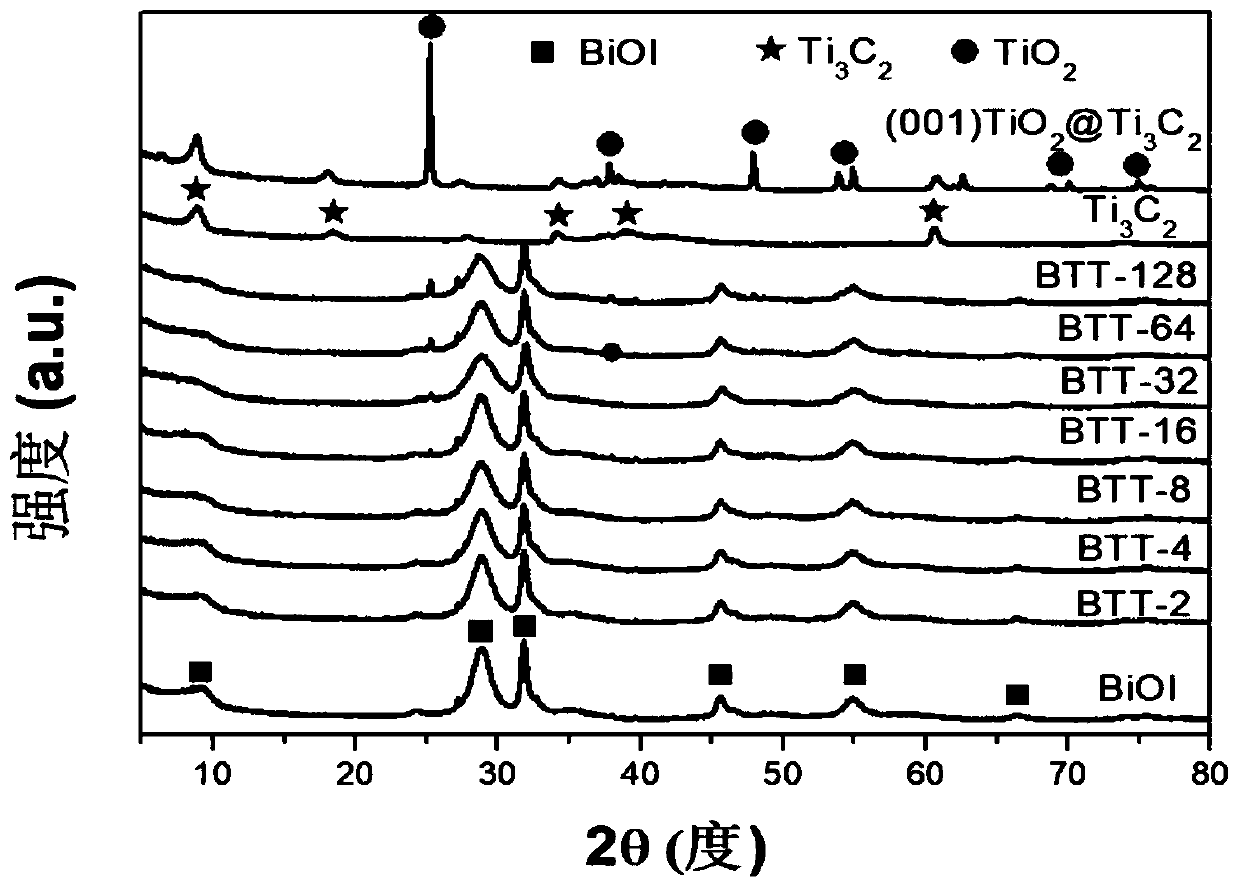

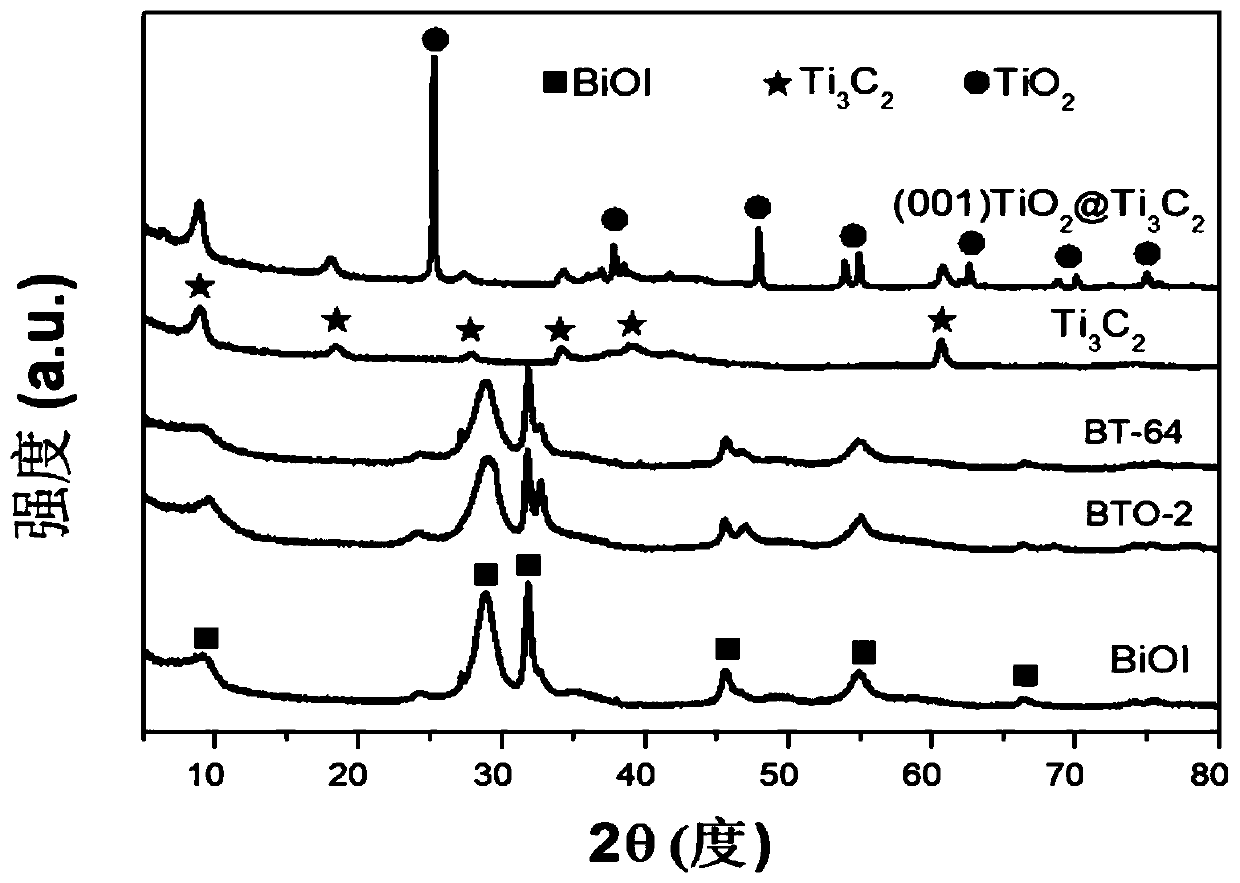

[0043] 3) the Mxene-Ti obtained in step 2) 3 C 2 Material, NaBF 4 Mix with hydrochloric acid according to the feed ratio of 0.5g:0.83g:80ml, magnetic stirring reaction at room temperature for 1h, then transfer to a high-temperature and high-pressure reactor, and react in a muffle furnace at 160°C for 12h. After the reaction, use ion and ethanol were washed 3 times, and then the resulting precipitate was vacuum-dried at 60 °C for 12 h to o...

Embodiment 2

[0047] The preparation process refers to the process in Example 1, the difference is that (001) TiO 2 @Ti 3 C 2 The dosage is 0.004g. After the reaction is completed, the BiOI@(001)TiO 2 @Ti 3 C 2 Material.

Embodiment 3

[0049] The preparation process refers to the process in Example 1, the difference is that (001) TiO 2 @Ti 3 C 2 The dosage is 0.008g. After the reaction is completed, the BiOI@(001)TiO 2 @Ti 3 C 2 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com