Preparation method of HP40 grade vacuum hot-pressing beryllium material and vacuum hot- pressing beryllium material

A technology of vacuum hot pressing and vacuum heat treatment, applied in the preparation of HP40 grade vacuum hot pressed beryllium material, and the field of HP40 vacuum hot pressed beryllium material, which can solve the problems of low elongation, poor strength and ductility, and low mechanical properties of beryllium material. , to achieve the effect of convenient operation, simple process, guaranteeing mechanical properties and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1, using cold flow impact to prepare beryllium powder, the beryllium powder has a beryllium content of 99.8%, an iron content of 800ppm and an average particle size of 14 μm.

[0029] Step 2, preheating the isostatic graphite mold and drying it, then sequentially loading the beryllium powder and vacuum hot pressing to obtain a shaped beryllium blank.

[0030] Wherein, the preheating temperature is 200° C., and the drying time is 12 hours. Vacuum degree is 6×10 -2 Pa, the holding temperature is 1100°C, and the holding pressure is 20MPa / cm 2 , The heat preservation and pressure holding time is 8 hours.

[0031] Step 3, using a hydraulic press to eject the formed beryllium blank, that is, vacuum heat treatment after demoulding, to obtain a HP40 vacuum hot-pressed beryllium material. Vacuum degree is 6×10 -2 Pa, the holding temperature is 750°C, and the holding time is 30 hours.

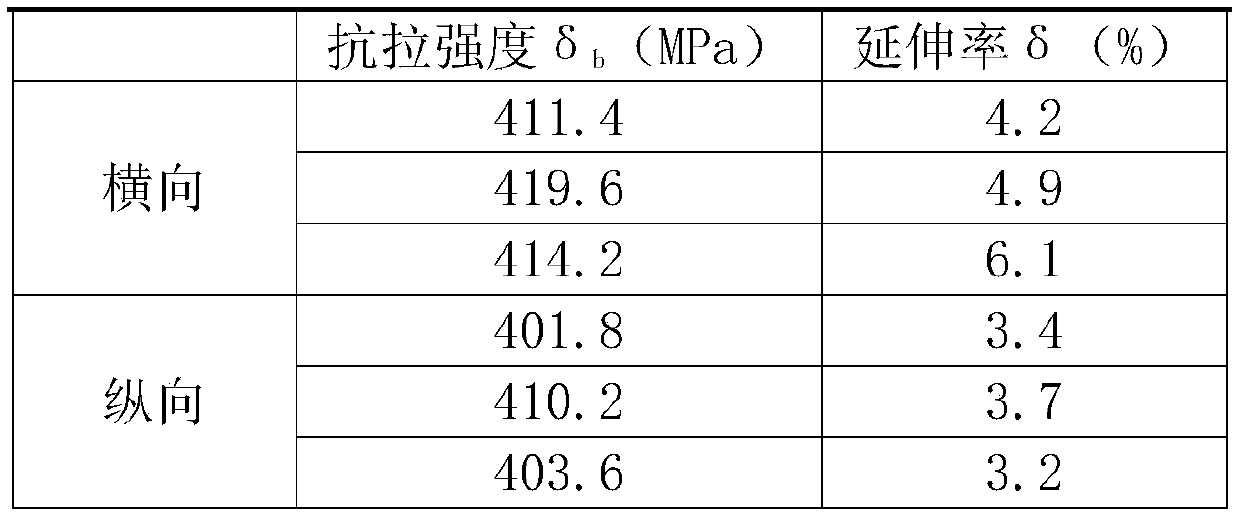

[0032] The performance parameters of the HP40 grade vacuum hot-pressed beryllium mat...

Embodiment 2

[0035] Step 1, using cold flow impact to prepare beryllium powder, the beryllium powder has a beryllium content of 99.6%, an iron content of 700ppm and an average particle size of 9 μm.

[0036] Step 2, preheating the mold of isostatic graphite and C / C material and drying and then loading the beryllium powder and vacuum hot pressing to obtain the formed beryllium blank.

[0037] Wherein, the preheating temperature is 180° C., and the drying time is 12 hours. Vacuum degree is 3×10 -2 Pa, the holding temperature is 1150°C, and the holding pressure is 15MPa / cm 2 , The heat preservation and pressure holding time is 3 hours.

[0038] Step 3, using a hydraulic press to eject the formed beryllium blank, that is, vacuum heat treatment after demoulding, to obtain a HP40 vacuum hot-pressed beryllium material. Vacuum degree is 3×10 -2 Pa, the holding temperature is 650°C, and the holding time is 10 hours.

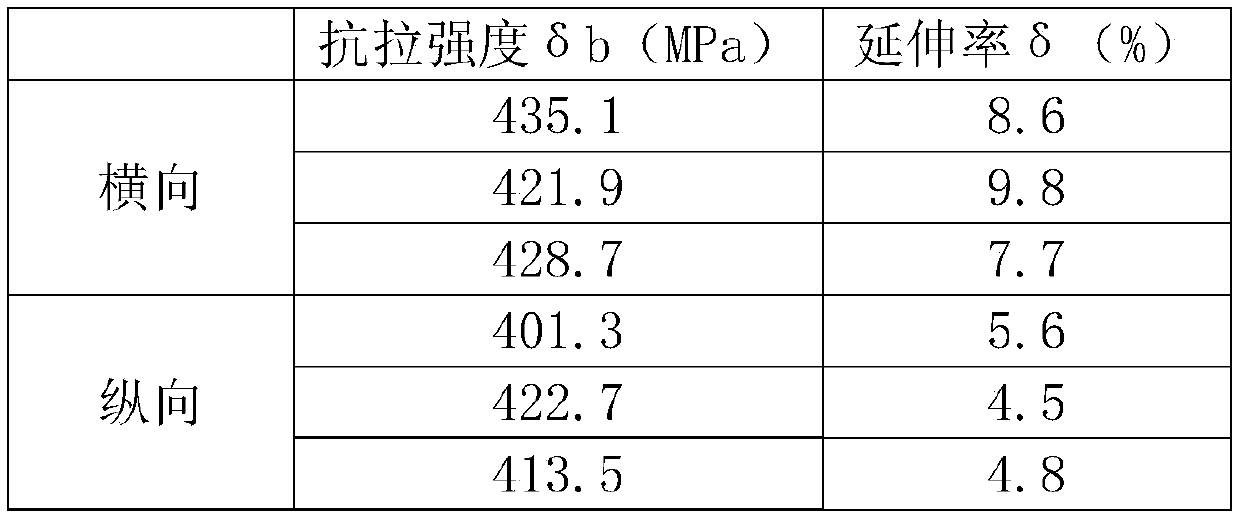

[0039] The performance parameters of the HP40 grade vacuum hot-pressed beryl...

Embodiment 3

[0042] Step 1, using cold flow impact to prepare beryllium powder, the beryllium powder has a beryllium content of 99.5%, an iron content of 750ppm and an average particle size of 6 μm.

[0043] Step 2, preheating the mold of isostatic graphite and C / C material and drying and then loading the beryllium powder and vacuum hot pressing to obtain the formed beryllium blank.

[0044] Wherein, the preheating temperature is 220° C., and the drying time is 20 hours. The vacuum degree is 4×10 -2 Pa, the holding temperature is 1190°C, and the holding pressure is 18MPa / cm 2 , The heat preservation and pressure holding time is 6 hours.

[0045] Step 3, using a hydraulic press to eject the formed beryllium blank, that is, vacuum heat treatment after demoulding, to obtain a HP40 vacuum hot-pressed beryllium material. The vacuum degree is 4×10 -2 Pa, the holding temperature is 700°C, and the holding time is 20 hours.

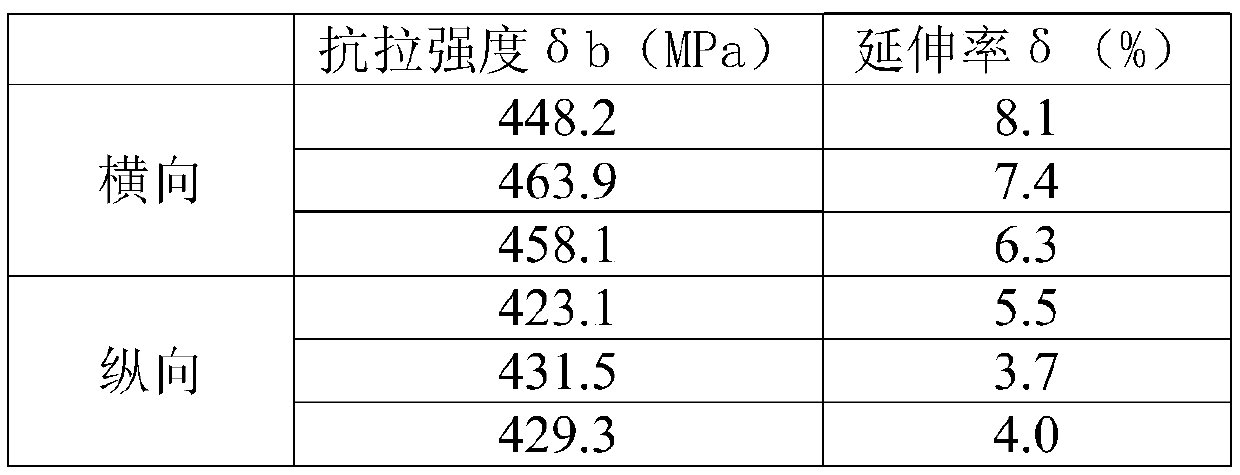

[0046] The performance parameters of the HP40 grade vacuum hot-press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com