Welding method of heavy-duty universal joint shaft intermediate shaft

A universal joint shaft and intermediate shaft technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of large difference in size between the upper and lower sides of the groove angle weld, early failure of the product, and large shrinkage, etc., to achieve production The effect of cost reduction, guaranteed performance and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

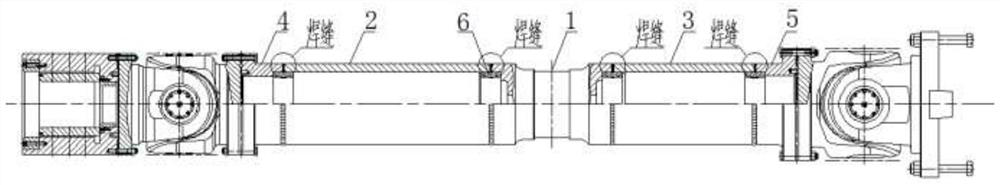

[0053] The rotation diameter of the 3500 wide and thick plate roughing line in a steel plant is as follows: The welding method of the present invention will be described in detail by taking a universal joint shaft of a rolling mill as an example.

[0054] The maximum power of the motor end of the connecting shaft is 8000KW, the motor speed is 45-90 rpm, and the design weight of the connecting shaft is 41.6 tons. According to the maximum transmission torque, fatigue torque, motor power and rotational speed, the transmission torque of the connecting shaft can be calculated to be 1698 (kN m), and the motor overload coefficient is 2.75. The maximum overload torque of the universal joint shaft used in this rolling line is 10200 ( kN m), the fatigue torque is 4830 (kN m).

[0055] The overall length of the whole heavy-duty universal joint shaft is 13.55 meters and the weight is 46.83 tons. The outer diameter of the welding part of the intermediate shaft is The length is 9.68 met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com