Hydrogen sulfide treatment method and device

A hydrogen sulfide and sulfuric acid technology, applied in chemical instruments and methods, sulfur compounds, sulfur preparation/purification, etc., can solve problems such as increasing production costs, prolonging hydrogen sulfide treatment process, etc., to improve efficiency and reduce elemental sulfur. The effect of producing and operating at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

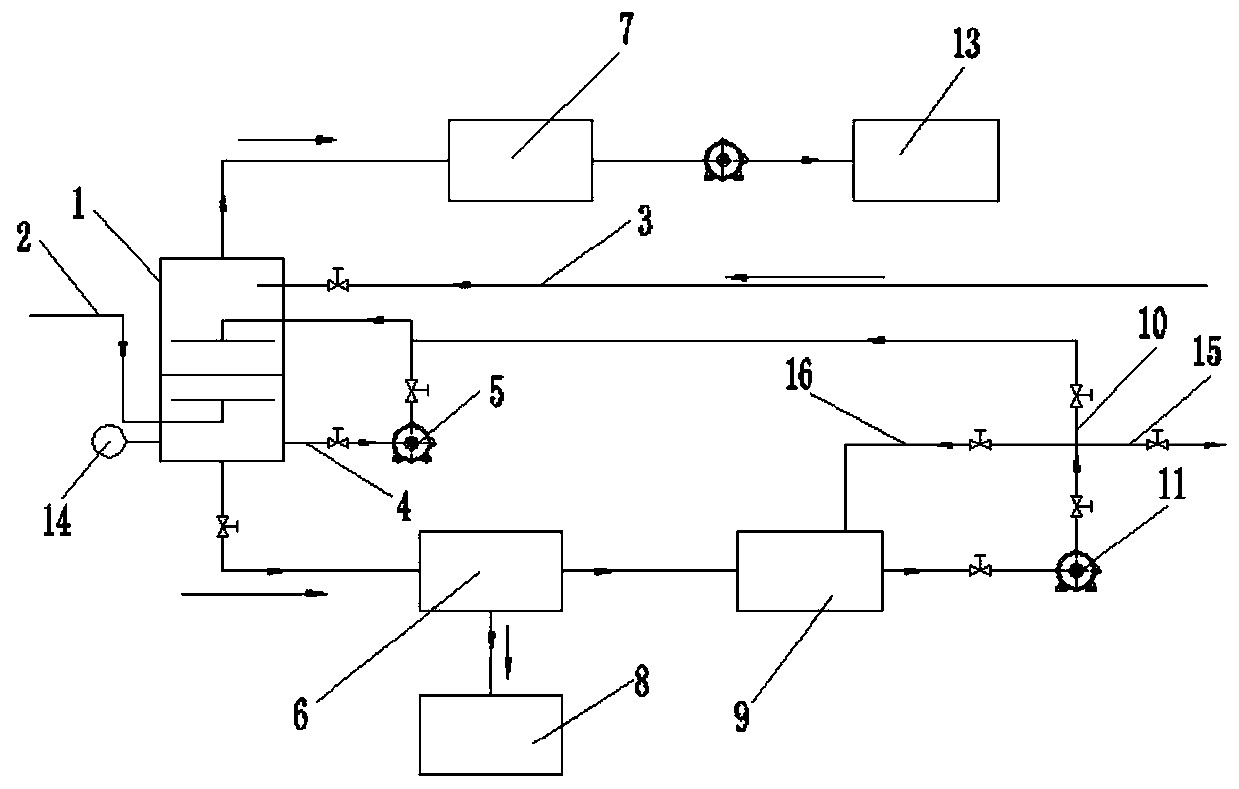

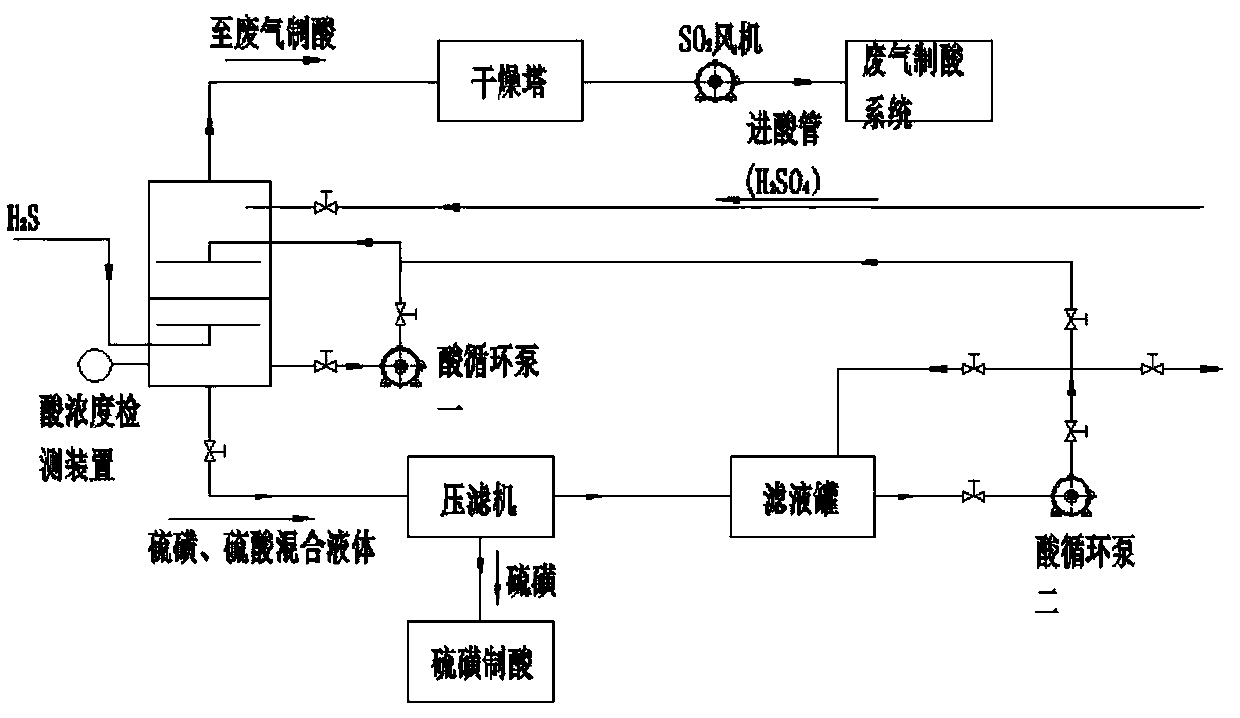

[0048] A method for treating hydrogen sulfide, comprising the steps of:

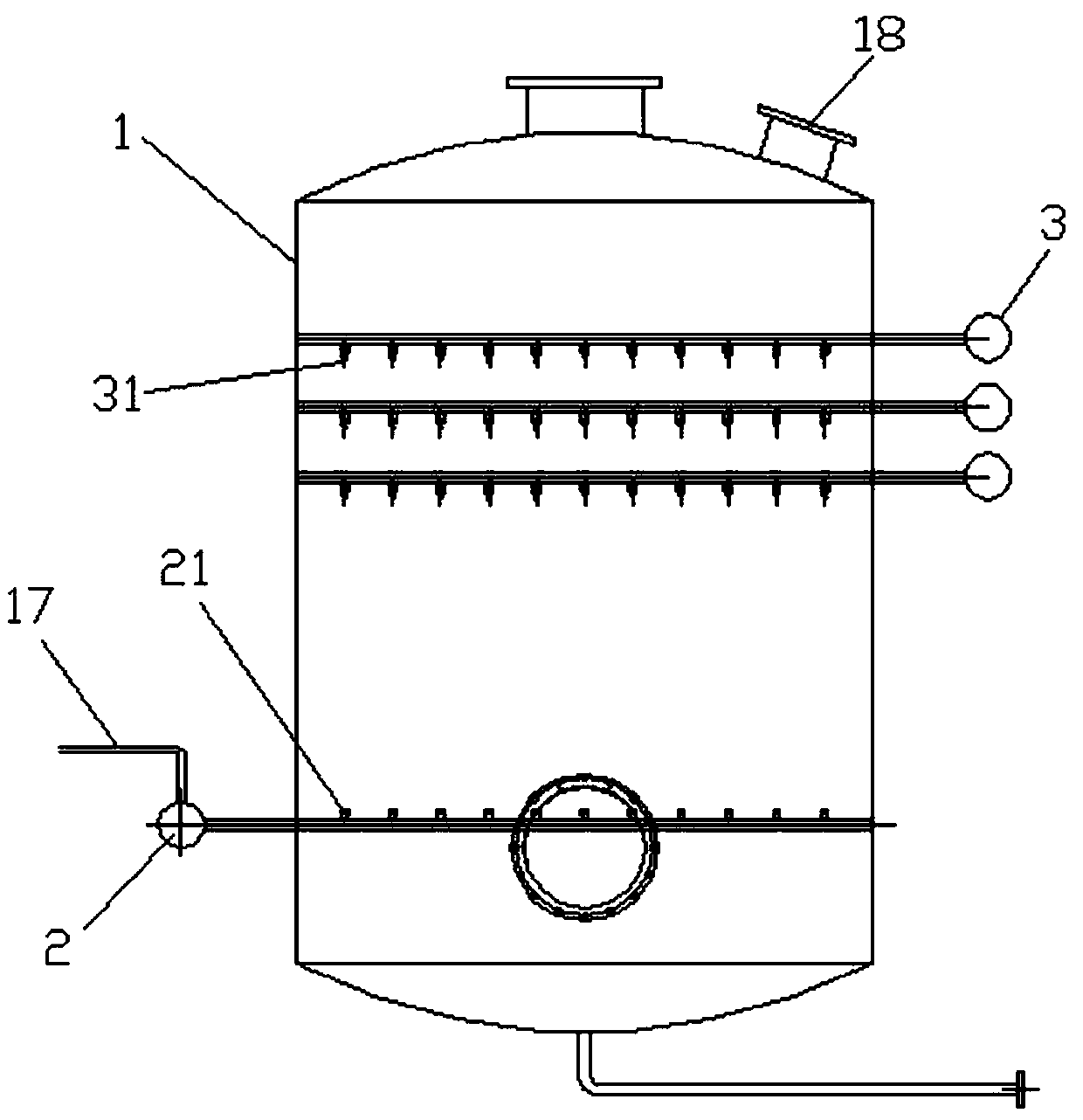

[0049] (a) Pass sulfuric acid into the reaction tank 1, then pass hydrogen sulfide into the sulfuric acid through aeration, and simultaneously pass the sulfuric acid in the reaction tank 1 into the reaction tank 1 repeatedly by spraying;

[0050] (b) the separation of sulfur dioxide and its use in the production of sulfuric acid;

[0051] (c) Separation of sulfur and use of the separated sulfur in the production of sulfuric acid.

[0052] Further, in step (a), hydrogen sulfide and sulfuric acid react under heating conditions, and the heating temperature is 65±10°C.

[0053] Further, the pressure in the reaction tank 1 in step (a) is negative pressure.

[0054] Further, the negative pressure is controlled from -0.9kpa to -2.0kpa.

[0055] Further, in step (a), the sulfuric acid spray pressure is 0.3-0.5Mpa, the spray flow rate is 80-150m³ / h; the hydrogen sulfide aeration pressure is 10±1.5kpa, and the ae...

Embodiment 2

[0066] A method for treating hydrogen sulfide, comprising the steps of:

[0067] (a) Pass sulfuric acid into the reaction tank 1, then pass hydrogen sulfide into the sulfuric acid through aeration, and heat the reaction tank 1 to make sulfuric acid and hydrogen sulfide react to produce sulfur dioxide as the main product. The sulfuric acid repeatedly passes in the reaction tank 1 by the mode of spraying;

[0068] (b) the separation of sulfur dioxide and its use in the production of sulfuric acid;

[0069] (c) Separation of sulfur and use of the separated sulfur in the production of sulfuric acid.

Embodiment 3

[0071] On the basis of Example 2, further, the heating temperature is 65±10°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com