Photocatalytic modified aggregate for self-cleaning concrete and preparation method thereof

A self-cleaning, concrete technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of not being able to continuously and effectively exert the photocatalytic self-cleaning function, and not having self-cleaning functional properties , to achieve the effect of improving self-cleaning performance and increasing contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

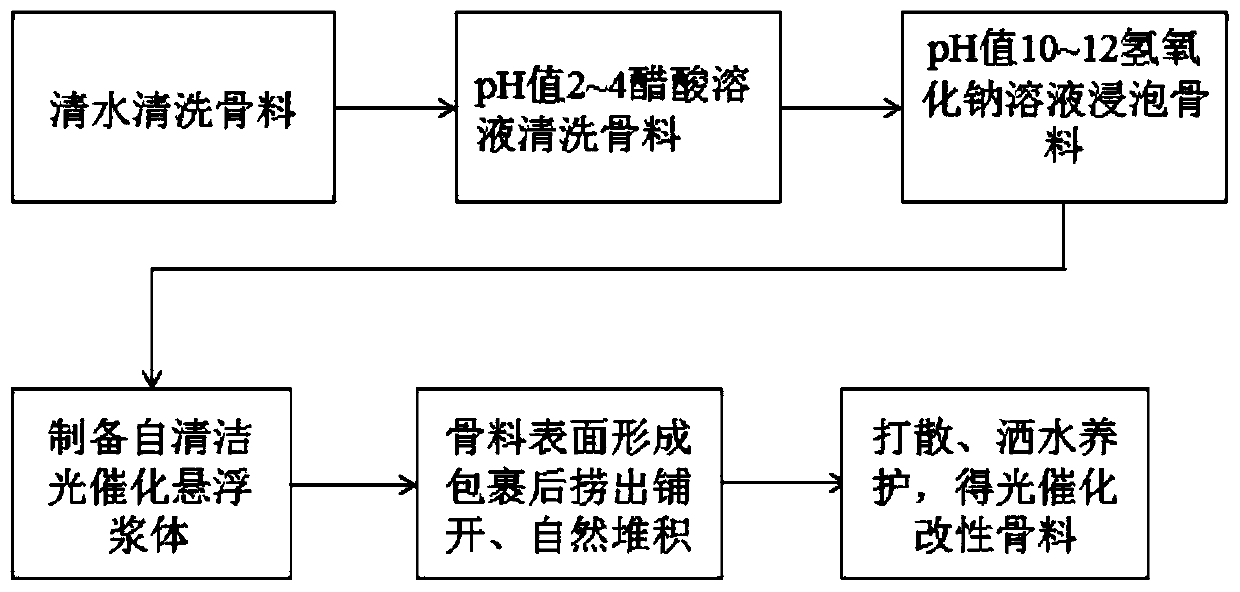

Method used

Image

Examples

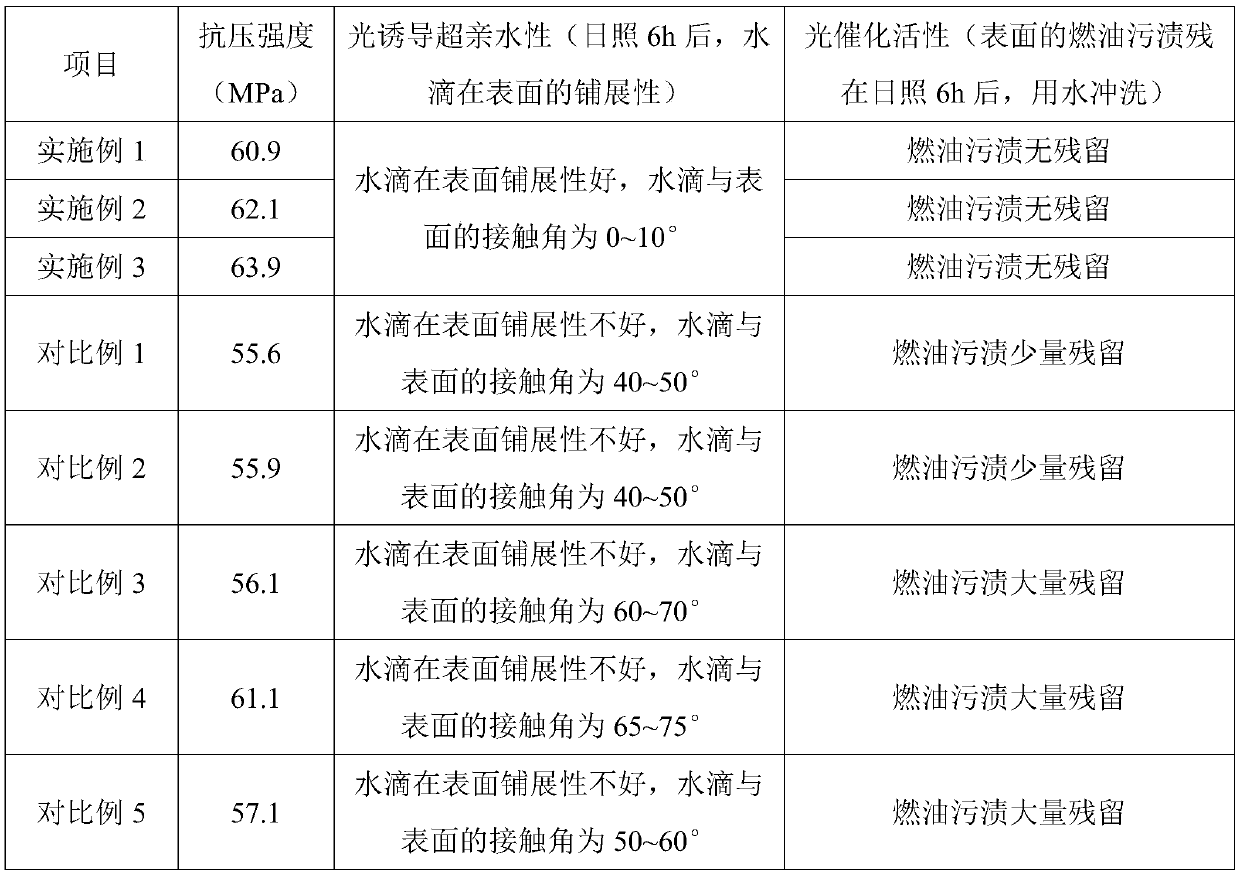

Embodiment 1

[0025] A photocatalytically modified aggregate for self-cleaning concrete, which is soaked in the cleaned and treated aggregate whose surface pH value is not lower than 10 The self-cleaning photocatalytic suspension slurry formed by water-retarding agent, retarding water reducer, water and thickener; the average thickness of the prepared photocatalytic modified aggregate surface slurry wrapping is not less than 100um and not more than 800um, and the wrapping area is not less than 100um. less than 95%.

[0026] Wherein, the particle diameter of the aggregate is not less than 2.35 mm, and may be non-porous aggregates such as river sand, machine-made sand, quartz sand, and stones. The mass ratio of cement, microsilica powder, nano titanium dioxide, microbead powder, quartz stone powder, dispersant, retarding water reducer, water, and thickener in the self-cleaning photocatalytic suspension slurry is 1:0.05 :0.05:0.10:0.05:0.0003:0.005:0.25:0.0001. The silicon dioxide content of...

Embodiment 2

[0044] This embodiment is the same as that of Embodiment 1 except for the composition in parts by weight of the self-cleaning photocatalytic suspension slurry. The mass ratio of cement, microsilica powder, nano titanium dioxide, microbead powder, quartz stone powder, dispersant, retarding water reducer, water, and thickener in the self-cleaning photocatalytic suspension slurry is 1:0.15 :0.10:0.20:0.15:0.006:0.02:0.4:0.0003.

Embodiment 3

[0046] This embodiment is the same as that of Embodiment 1 except for the composition in parts by weight of the self-cleaning photocatalytic suspension slurry. The mass ratio of cement, microsilica powder, nano titanium dioxide, microbead powder, quartz stone powder, dispersant, retarding water reducing agent, water and thickener in the self-cleaning photocatalytic suspension slurry is 1:1 :0.075:0.15:0.10:0.0045:0.0125:0.325:0.0002.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com