Synergistic leaching solution for chromium slag left place with heavy metal polluted soil and applications thereof

A technology for contaminated soil and heavy metals, applied in the restoration of contaminated soil, application, soil conditioning materials, etc., can solve the lack of simultaneous removal, no synergistic leaching-plant joint restoration method, and the diversity of microbial ecological functions in the soil environment Take into account the recovery of stability and other issues, so as to improve the removal rate of leaching and promote the effect of desorption and release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

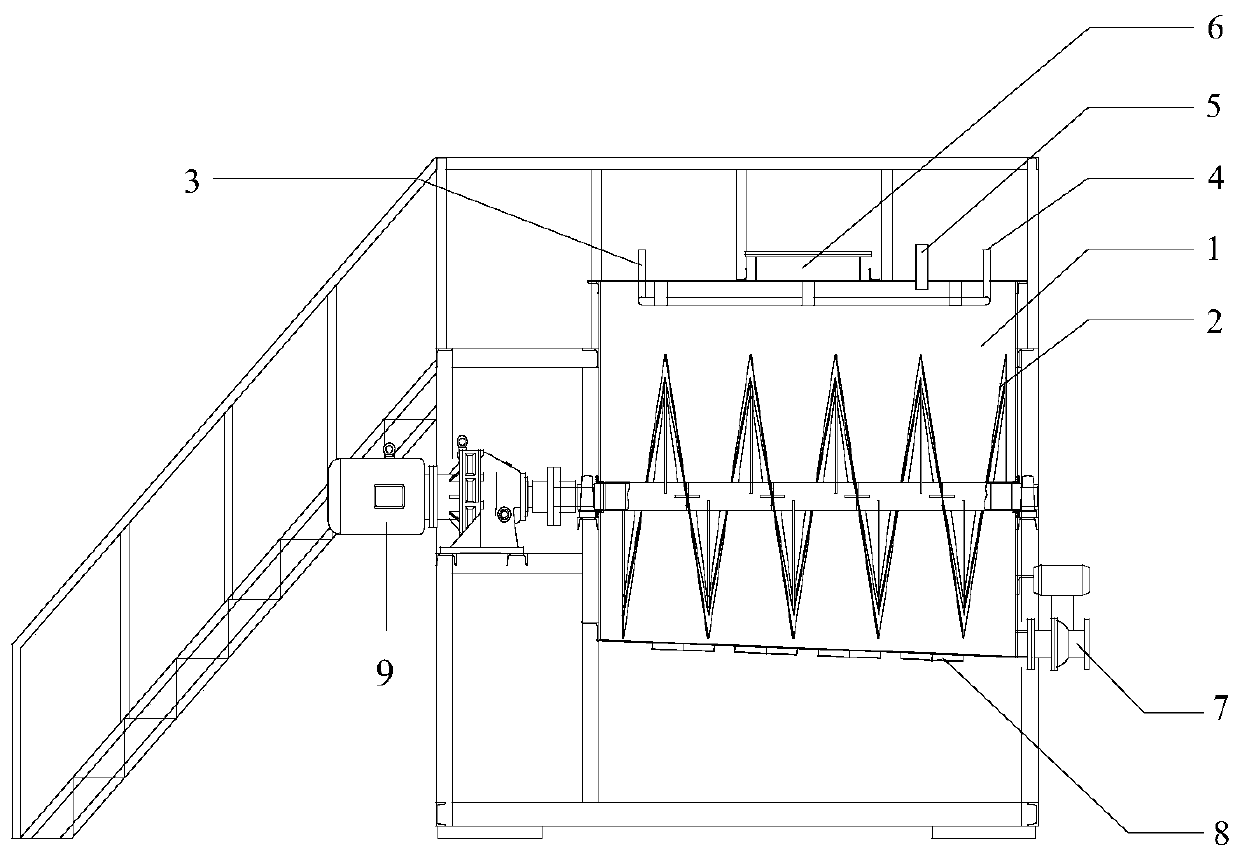

Image

Examples

Embodiment 1

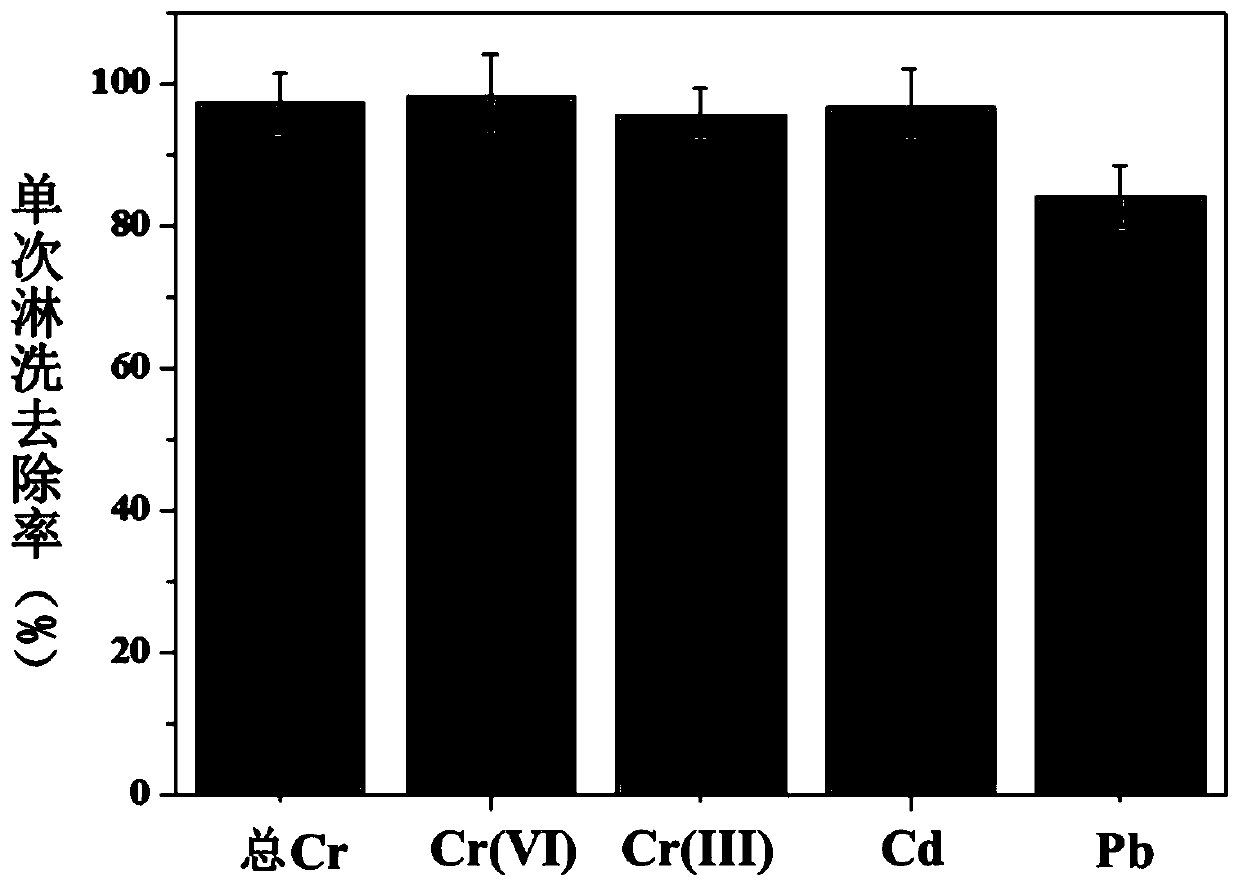

[0037] For total Cr concentration greater than 1000 mg kg -1 And less than 5000 mg kg -1 , Pb concentration greater than 1000 mg kg -1 And less than 2000 mg kg -1 , Cd concentration greater than 1 mg kg -1and less than 10 mg kg -1 Chromium slag left over polluted soil:

[0038] The test soil was collected from a chromium residue site in Tianqiao District, Jinan City, Shandong Province. The soil samples were air-dried, the impurities were sorted out, and the soil samples were passed through a 10-mesh sieve for later use. The basic physical and chemical properties of the soil are pH 7.9, organic matter content 32.7 g kg -1 , total nitrogen 1.1 g kg -1 , available nitrogen 35.2 mg kg -1 , total phosphorus 0.4 g kg -1 , available phosphorus 31.6 mg kg -1 . The mechanical composition of the soil is 11.2 wt.% sand, 65.5 wt.% soil, and 23.3 wt.% clay. The background pollution concentrations of total chromium, hexavalent chromium and trivalent chromium in soil were 2343.1 ...

Embodiment 2

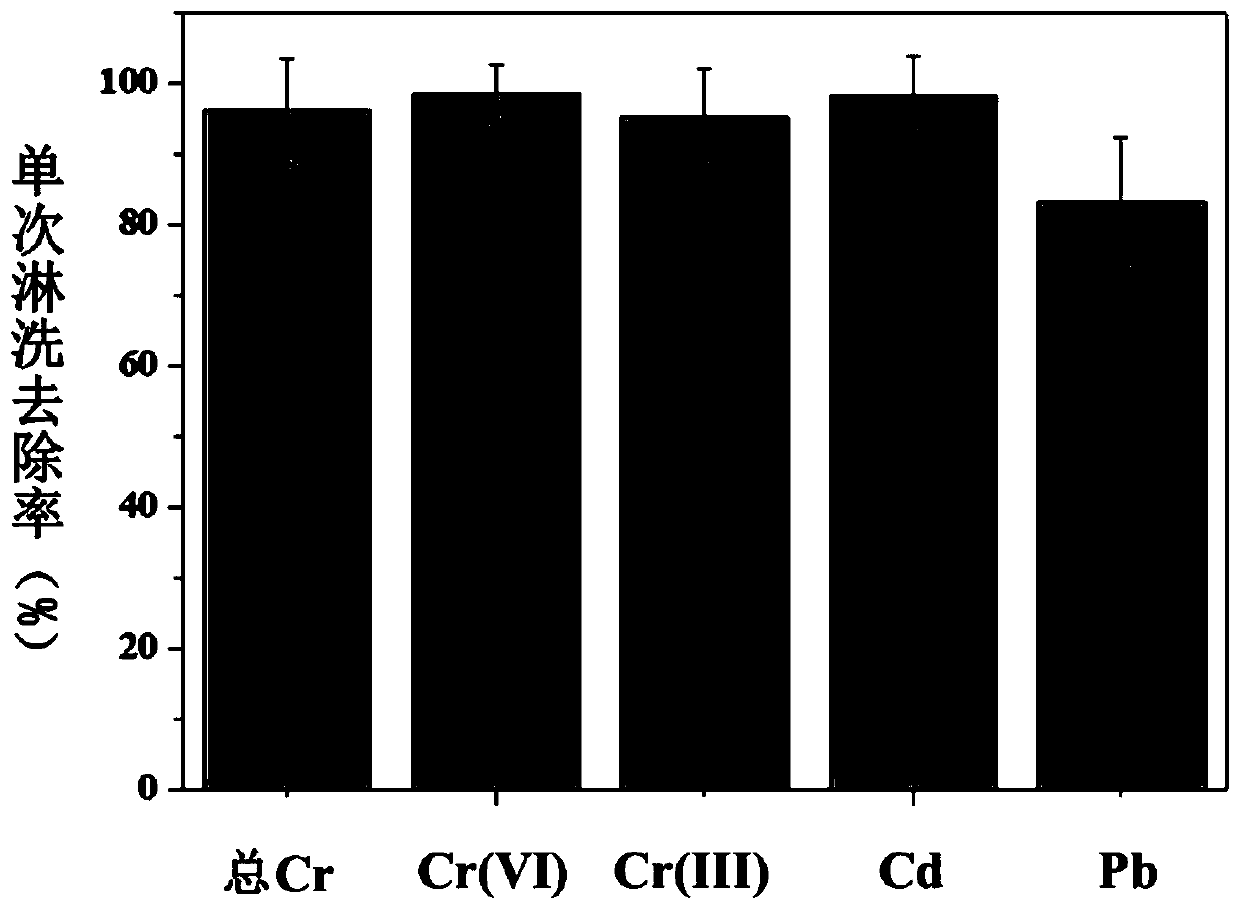

[0044] For total Cr concentration greater than 5000 mg kg -1 And less than 10000 mg kg -1 , Pb concentration greater than 2000 mg kg -1 And less than 5000 mg kg -1 , Cd concentration greater than 10 mg kg -1 And less than 100 mg kg -1 Chromium slag left over polluted soil:

[0045] The test soil was collected from a chromium slag legacy site in Luzhou City, Sichuan Province. The soil samples were air-dried, the impurities were sorted out, and the soil samples were passed through a 10-mesh sieve for later use. The basic physical and chemical properties of the soil are pH 8.1 and organic matter content 12.5 g kg -1 , total nitrogen 1.6 g kg -1 , available nitrogen 28.3mg kg -1 , total phosphorus 0.2 g kg -1 , available phosphorus 31.2 mg kg -1 . The mechanical composition of the soil is 15.4 wt.% sand, 64.2 wt.% soil, and 20.4 wt.% clay. The background pollution concentrations of total chromium, hexavalent chromium and trivalent chromium in soil were 8490.9 ±453.5 mg...

Embodiment 3

[0051] For total Cr concentration greater than 10000 mg kg -1 , Pb concentration greater than 5000 mg kg -1 , Cd concentration greater than 100 mgkg -1 Chromium slag left over polluted soil:

[0052] The test soil was collected from a site left over from chromium slag in Changsha City, Hunan Province. The soil samples were air-dried, the impurities were sorted out, and the soil samples were passed through a 10-mesh sieve for later use. The basic physical and chemical properties of the soil are pH 8.5, organic matter content 26.6 g kg -1 , total nitrogen 2.1 g kg -1 , available nitrogen 42.1mg kg -1 , total phosphorus 0.3 g kg -1 , available phosphorus 23.6 mg kg -1 . The soil mechanical composition is 18.9 wt.% sand, 69.2 wt.% loam, and 11.9 wt.% clay. The background pollution concentrations of total chromium, hexavalent chromium and trivalent chromium in soil were 14467.3 ±1543.2 mg kg -1 , 12938.3 ± 1345.3 mg kg -1 and 1529.5 ± 121.3 mg kg -1 . The background po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com