Isolation type leaf spring steel sheet preparing device and method

A technology for preparing devices and leaf springs, which is applied in quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of deformation and fracture of spring steel strips, high risk factors, and serious pollution, so as to reduce risks, eliminate environmental pollution, and control The effect of temperature drop efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

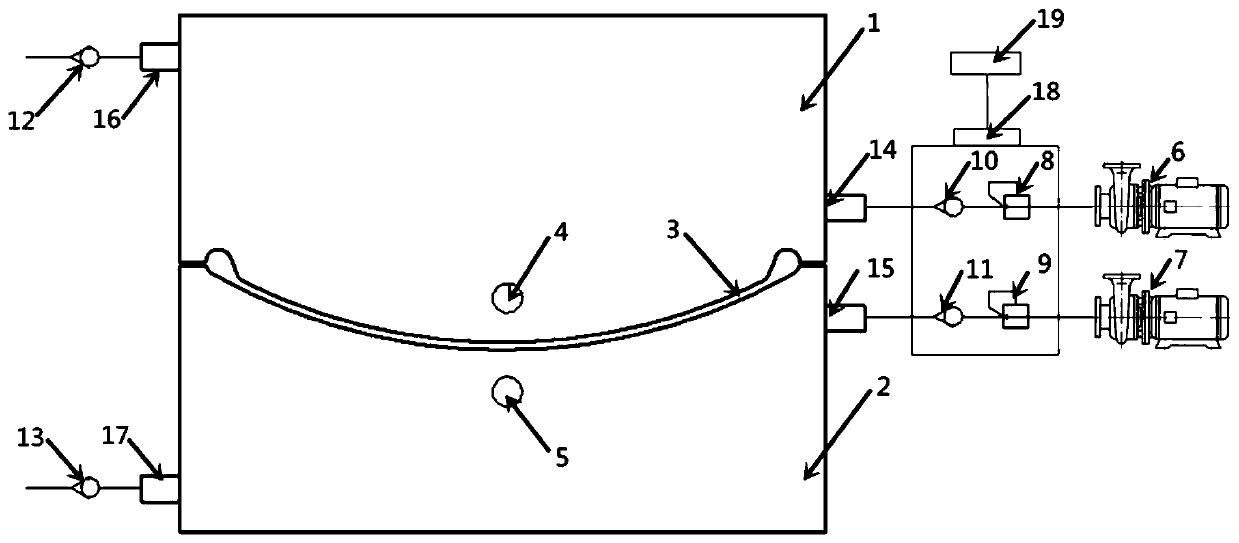

[0020] In order to further illustrate the feasibility and practicability of the invention patent, the invention patent will be described in detail in combination with schematic diagrams.

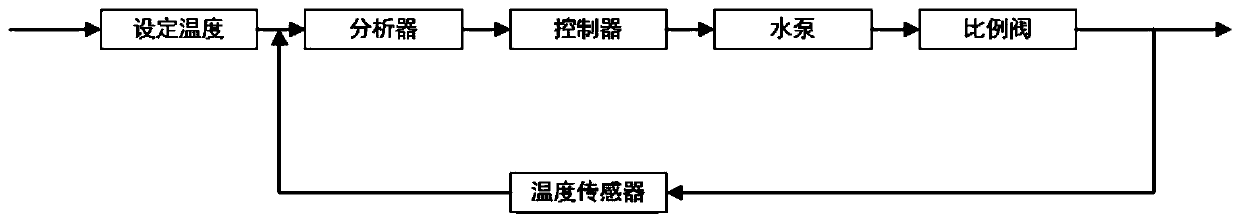

[0021] An isolated leaf spring steel sheet preparation device and method, such as figure 1 As shown, including upper cooling box 1, lower cooling box 2, leaf spring steel sheet 3, temperature sensor I4, temperature sensor II5, circulation pump I6, circulation pump II7, proportional valve I8, proportional valve II9, check valve I10, single Directional valve II11, one-way valve III12, one-way valve IV13, water inlet joint I14, water inlet joint II15, water outlet joint I16, water outlet joint II17, analyzer 18, controller 19. The upper cooling tank 1 is connected to the water inlet joint I14 and the water outlet joint I16 respectively, the one-way valve I10 is connected to the water inlet joint I14 to prevent the water in the upper cooling tank 1 from flowing back, and the water outlet joint I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com