Engine room cover applied to wind power generation and production technology thereof

A technology of production process and nacelle cover, which is applied in the field of nacelle cover and its production process, can solve the problems of material impact, product quality, and work efficiency, and achieve the advantages of easy installation and disassembly, improved space utilization, and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

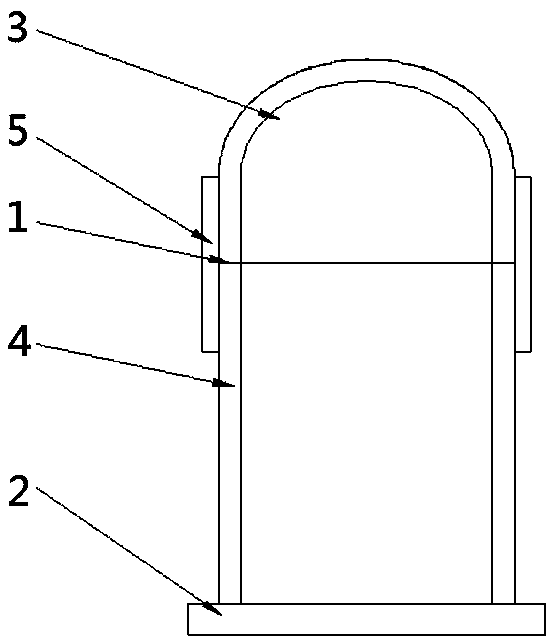

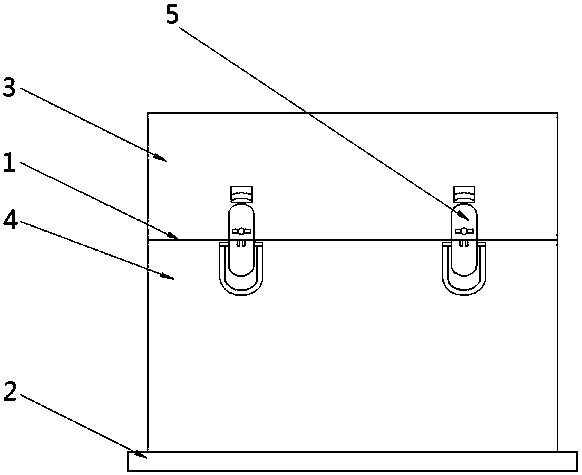

[0053] see Figure 1-5 , a nacelle cover applied to wind power generation, including a cover body 1 and a bottom plate 2, the cover body 1 and the bottom plate 2 are connected by bolts, the contact between the cover body 1 and the bottom plate 2 is provided with a gasket, and the cover body 1 includes an upper Four sets of fast locking mechanisms 5 are provided at the joints of the cover body 3 and the lower cover body 4 , and the upper cover body 3 and the lower cover body 4 .

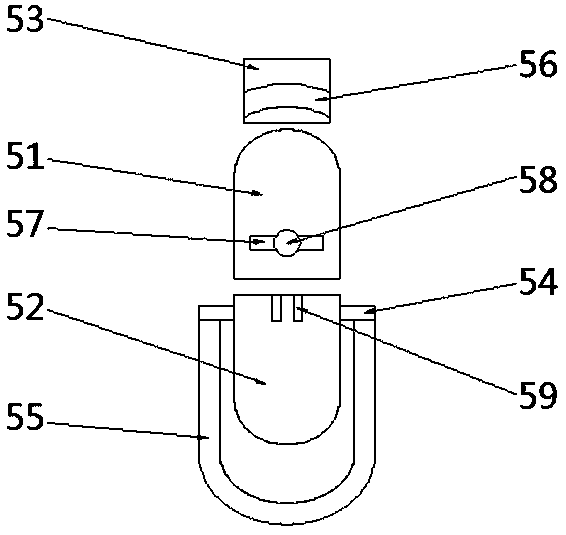

[0054] The quick locking mechanism 5 includes an upper positioning block 51, a lower positioning block 52 and a clamping block 53, the upper positioning block 51 is fixed at the lower edge of the upper cover body 3, and the lower positioning block 52 is fixed at the upper edge of the lower cover body 4, The clamping block 53 is fixed on the upper side of the upper positioning block 51, the lower positioning block 52 is fixed with a pin shaft 54, the end of the pin shaft 54 is fixed with a clasp 55, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com