High-performance lithium-sulfur battery diaphragm and preparation method and application thereof

A lithium-sulfur battery, high-performance technology, used in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

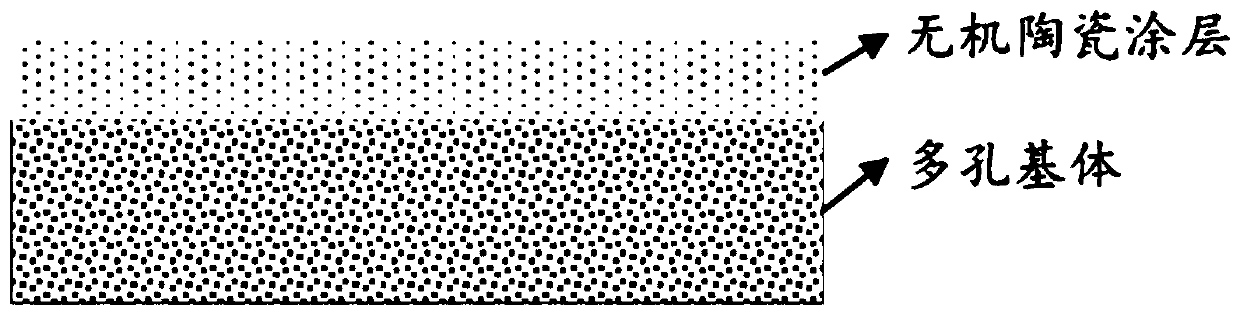

[0033] The preparation method of the high-performance lithium-sulfur battery diaphragm of the present invention comprises the following steps:

[0034] Step 1, extruding ultra-high molecular weight polyethylene (molecular weight 300,000 to 2,000,000), pore forming agent (paraffin oil, 50% to 70%), carbon nanotubes, conductive carbon black and / or graphene through twin-screw extrusion The sheet is obtained by melting, plasticizing, mixing and extruding, and then cooled by the casting roll to form a film with a thickness of 500-1500 μm. The temperature of the casting roll is 10-60 ° C. The obtained sheet is biaxially stretched ( Longitudinal and horizontal) systematic hole expansion and mechanical strength improvement to obtain a film with uniform thickness, the film is extracted by solvent, the paraffin oil is washed out, and then shaped by the shaping equipment, that is, the honeycomb porous diaphragm substrate is prepared. Among them, the magnification of longitudinal stretchi...

Embodiment 1

[0040] The preparation method of the high-performance lithium-sulfur battery diaphragm of this embodiment comprises the following steps:

[0041] Step 1, melting, plasticizing, mixing and extruding 20% of ultra-high molecular weight polyethylene, 70% of pore-forming agent paraffin oil, 3% of carbon nanotubes and 7% of conductive carbon black through a twin-screw extruder to obtain a sheet, and then After being cooled by the casting roll, a film with a thickness of 500 μm is formed, and the temperature of the casting roll is 10°C; the obtained sheet is expanded by a biaxial stretching system and the mechanical strength is improved to obtain a film with uniform thickness. The film is extracted by solvent, and the paraffin wax The oil is washed out, and then shaped by the setting equipment to prepare a honeycomb porous diaphragm matrix. Among them, the magnification of longitudinal stretching is 5 times, and the stretching temperature is 90°C; the magnification of transverse st...

Embodiment 2

[0045] The preparation method of the high-performance lithium-sulfur battery diaphragm of this embodiment comprises the following steps:

[0046] Step 1. Melt, plasticize, mix and extrude 40% ultra-high molecular weight polyethylene, 50% pore-forming agent paraffin oil, 5% carbon nanotubes and 5% graphene through a twin-screw extruder to obtain a sheet, and then pass through The casting roll is cooled to form a film with a thickness of 1000 μm, and the temperature of the casting roll is 25°C; the obtained sheet is expanded through a biaxial stretching system and the mechanical strength is improved to obtain a film with uniform thickness. The film is extracted by solvent, and the paraffin oil Washing out, and then passing through the setting equipment to set the shape, the honeycomb-shaped porous diaphragm matrix is prepared. Among them, the magnification of longitudinal stretching is 7 times, and the stretching temperature is 95°C; the magnification of transverse stretching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com