Novel permanent magnet electronic gearbox for automobile

A technology of permanent magnet electronics and gearbox, which is applied in the field of gearbox, which can solve the problems of obvious system vibration and high energy consumption of the motor, and achieve the effect of automatically adjusting the speed, reducing vibration, reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

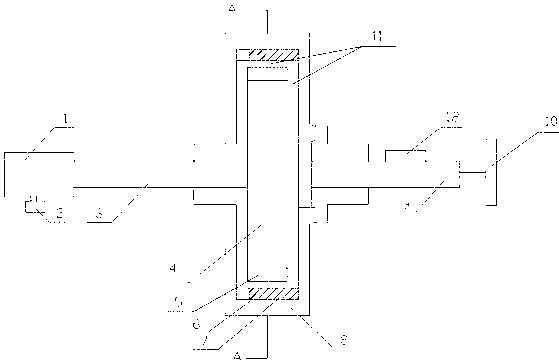

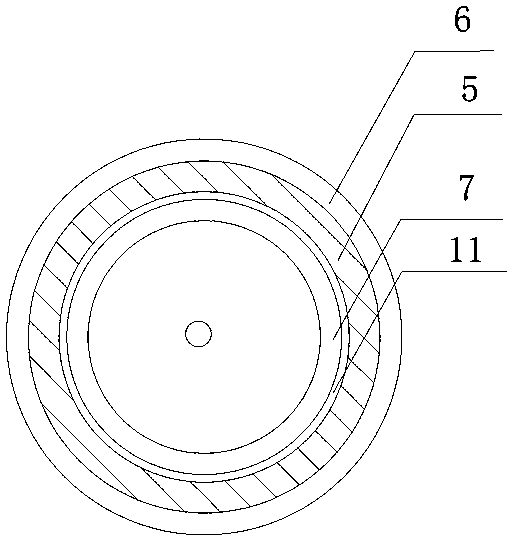

[0016] The invention is further described in conjunction with the accompanying drawings.

[0017] like figure 1 and figure 2 , the engine 1 is connected with the electronic control system 2 and the motor shaft 3, the motor shaft 3 is connected with the conical magnetic rotor 4, and the permanent magnets 5 are evenly arranged around the magnetic rotor 4; The rotor 6 is composed of a circular bottom surface and an annular side surface, the inner side of the annular side is a copper conductor 7, and the outer side is a steel body 8; the conductor rotor 6 is connected to the drive shaft 9, and the drive shaft 9 is connected to the drive wheel 10. An air gap 11 is formed between the conductor rotor 6 and the magnetic rotor 4; the spline 12 is connected with the drive shaft 9.

[0018] In the actual use of the invention, the electronic control system 2 controls the motor shaft 3, and the motor shaft 3 is connected with the magnetic rotor 4, thereby realizing the control of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com