Container type photovoltaic power generation system

A photovoltaic power generation system and containerized technology, applied in photovoltaic power generation, photovoltaic power stations, photovoltaic modules, etc., can solve the problems of project construction period limited by climate, low energy conversion efficiency, difficult quality control, etc., to ensure the center distance, avoid The effect of separation and reduction of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

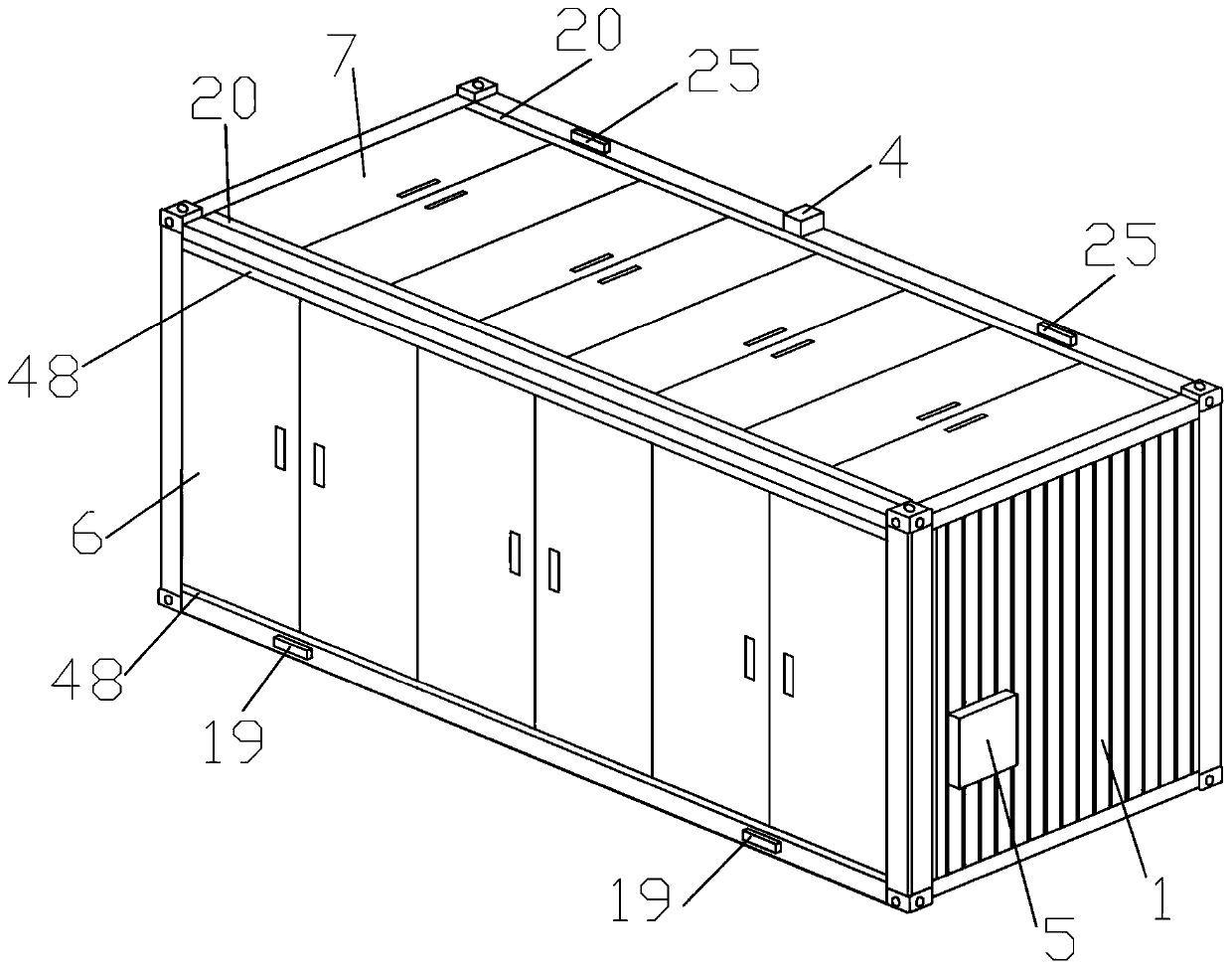

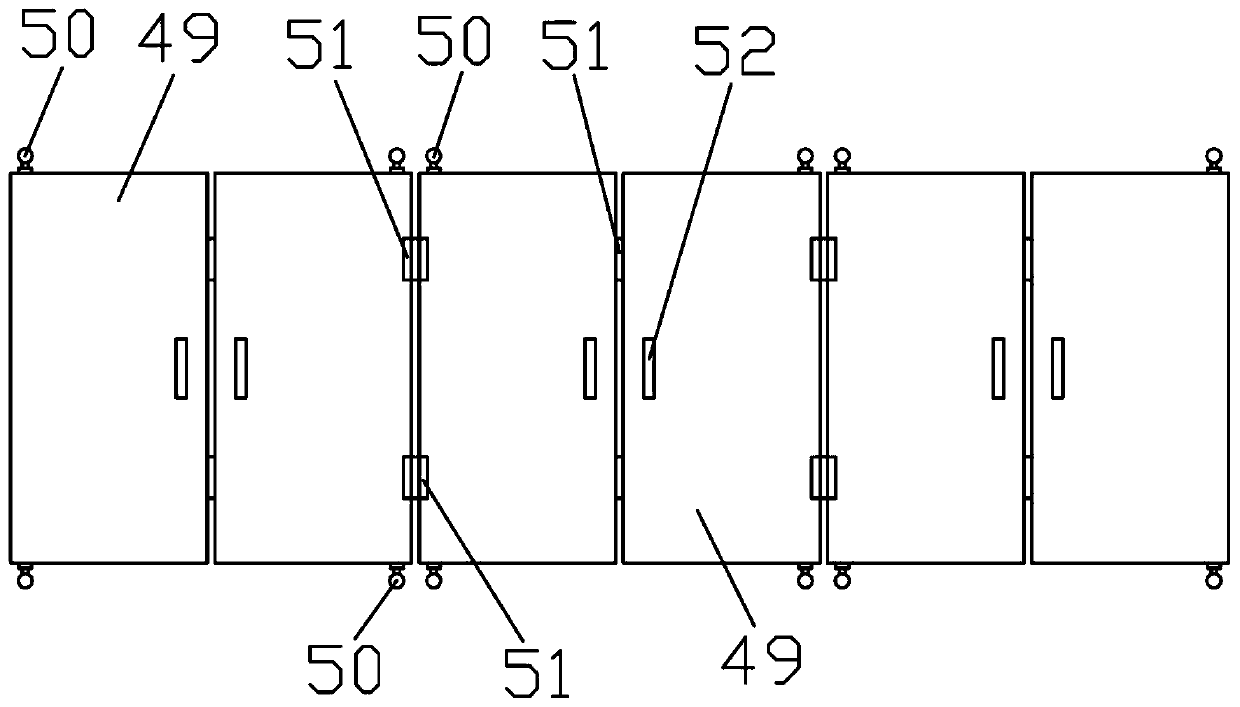

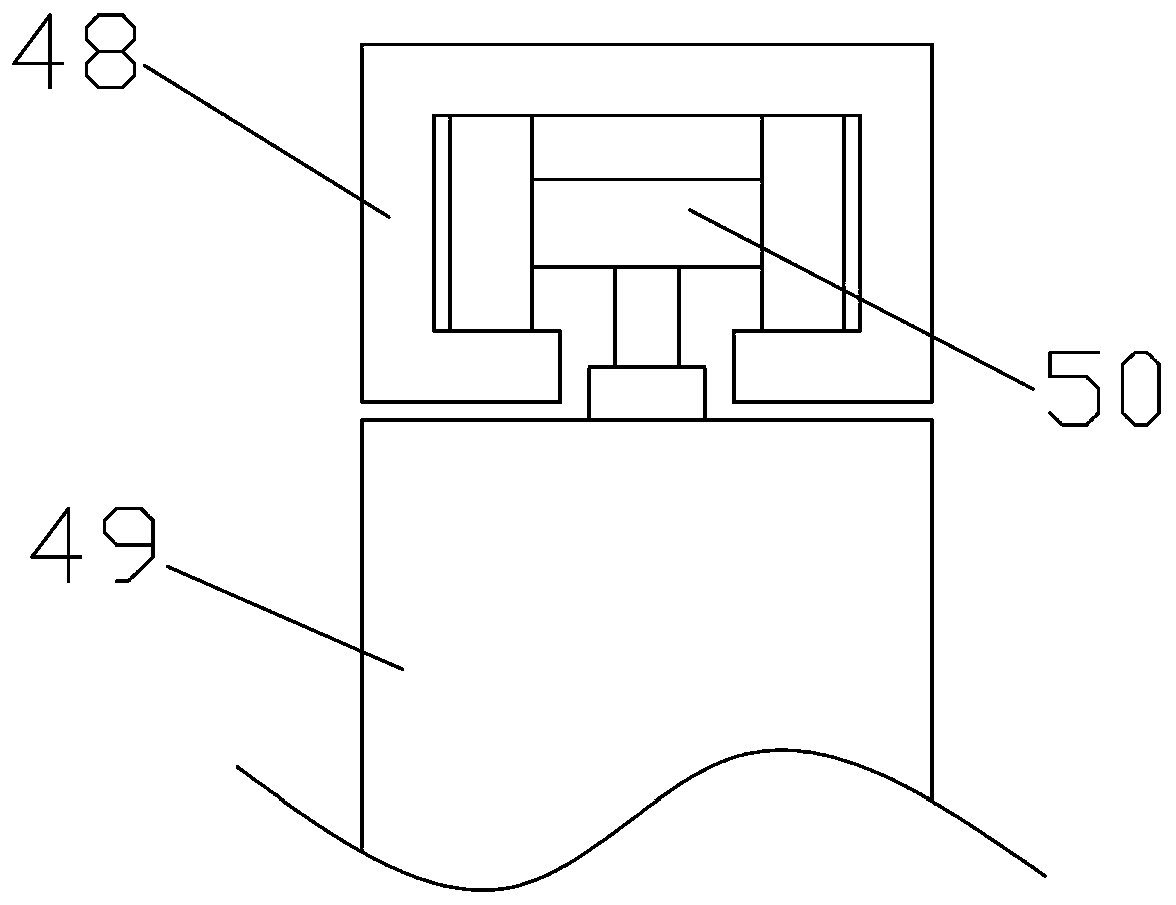

[0037] Embodiment: a kind of containerized photovoltaic power generation system, such as Figure 1-Figure 17 As shown, it includes a container 1, a first photovoltaic module 2, a second photovoltaic module 3, a sun tracking sensor 4 and a controller 5. The left and right sides and the top of the container 1 are open, and the left and right sides of the container 1 are respectively There is a first cover mechanism 6 for closing or opening the left and right sides of the container 1, and the top of the container 1 is provided with a second cover mechanism 7 for closing or opening the top of the container 1, and the container 1 is fixedly installed with A partition 8, the partition 8 divides the space in the container 1 into an upper storage chamber 9 and a lower storage chamber 10, the first photovoltaic assembly 2 is located in the upper storage chamber 9, and the second photovoltaic assembly 3 is respectively located in The left and right sides in the lower chamber 10.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com