High-color-fastness environment-friendly transfer paper

A technology of high color fastness and transfer paper, which is applied in the direction of decorative art and the process for producing decorative surface effects, etc., can solve the problems of increasing process costs and achieve the effect of improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

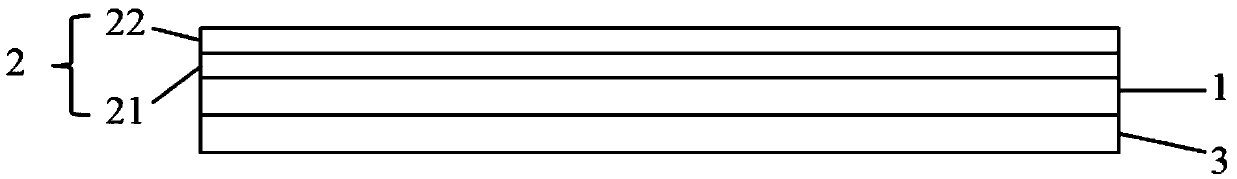

[0064] In the embodiment of the present invention, to make the coating required for the adsorption function layer 21, take 20 parts of 200 mesh calcium carbonate and 10 parts of gelatinizable starch in a water-soluble pot at 85°C to make the coating for the adsorption function layer 21. And use a 40 μm wire rod to scrape coat the surface of 80g base paper layer 1, dry and flatten, and measure the dry coating amount of the above-mentioned adsorption function layer 21 to be 10g. Then on the surface of the adsorption function layer 21, the printing ink layer 22 containing 5 parts of sodium carboxymethylcellulose and 5 parts of hydrophobic starch is coated with a 40 μm silk bar, dried and flattened, and the dry coating amount of the printed ink layer is 5g; Finally, 1g of anti-bend coating is coated on the back of the base paper layer 1, and the measured weight of the finished transfer paper is 98g. Wherein, the adsorption function layer 21 and the printing ink layer 22 together c...

Embodiment 2

[0068] In the embodiment of the present invention, 18 parts of 150-mesh kaolin and 8 parts of carboxymethylcellulose sodium were stirred and dissolved in a water-soluble pot at 70°C to make a coating for the adsorption function layer 21, and scrape-coated on 75g of base paper with a 50μm silk rod The surface of layer 1 was dried and flattened, and the dry coating weight of the adsorption function layer 21 was measured to be 12g. Finally, the surface of the above-mentioned adsorption function layer 21 is coated with a printing ink layer containing 6 parts of sodium carboxymethylcellulose and 5 parts of coral powder with a 40 μm silk rod, dried and flattened, and the dry coating amount of the above-mentioned printed ink layer is It is 6g. In addition, 2 g of anti-bending back coating was coated on the back of the paper sample, and the measured weight of the finished transfer paper was 95 g.

[0069] A prior art transfer paper not including an adsorption function layer was selec...

Embodiment 3

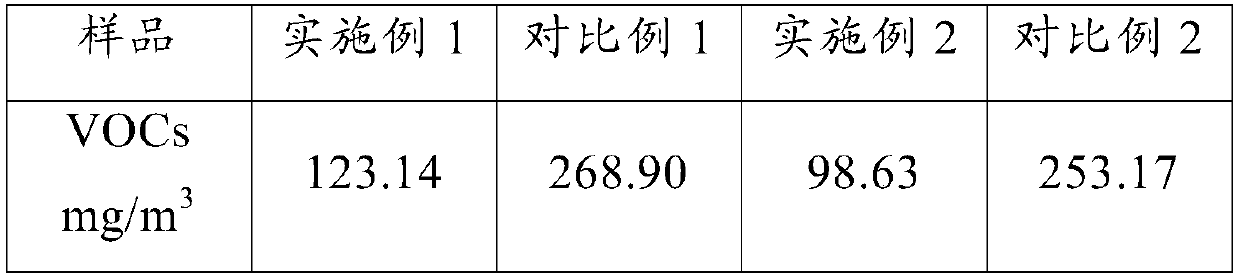

[0072] Embodiment 1, comparative example 1, embodiment 2 and comparative example 2 are transferred under exactly the same conditions, that is, patterns and fabrics of the same size are used during transfer printing, and they are under the same temperature and time conditions. The transfer is carried out under the vacuum transfer machine, that is, there is a vacuum suction device under the pressure plate of the transfer machine. After the pressure plate of the transfer machine is pressed down, the lower backing plate will absorb air to collect the gas generated during the transfer in a certain volume. In the balloon, use the PGD2-B-VOC portable VOC gas concentration meter to measure the VOC concentration. The test results are shown in the following table:

[0073]

[0074] By comparing the VOC concentration of the same volume of gas produced by transfer under the same conditions, it can be seen that the VOC emissions of Examples 1 and 2 can be reduced by 54-61% compared with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com