Safe and environment-friendly metal continuous derusting method and device

A safe, environmentally friendly, metal technology, applied in metal rust removal methods and fields, can solve problems such as troublesome cleaning, easy agglomeration, environmental hazards, etc., and achieve the effect of rapid cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

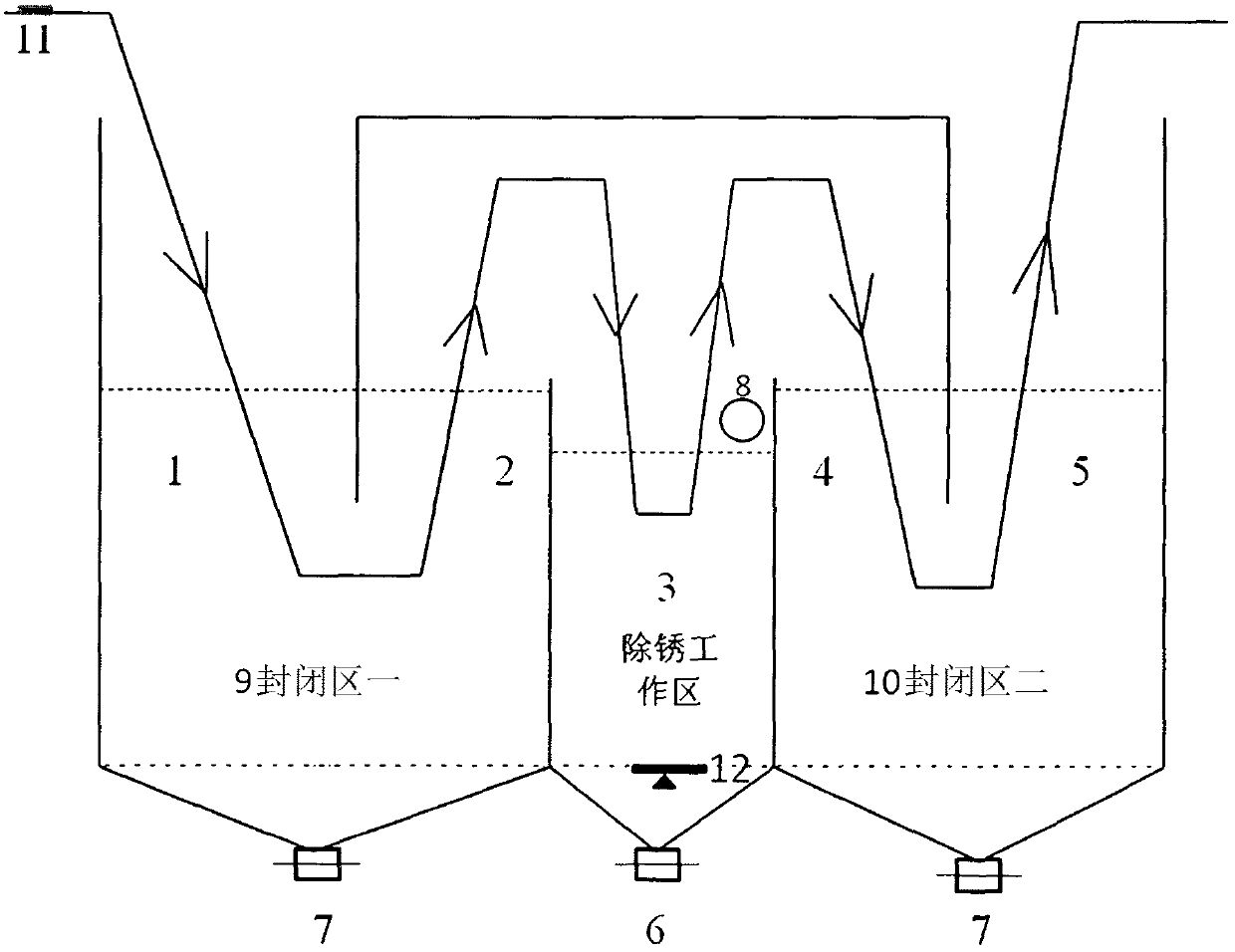

[0049] The present invention "a safe and environment-friendly metal continuous rust removal method and device" provides a metal chemical pickling solution (rust remover), the composition of which includes: 25% sulfuric acid, 0.3% thiourea; Oxide skin; rust removal process conditions: temperature 60 ° C, time 30 min; operation method: first add a certain height of water (sealing liquid) to the tank body ① and tank body ⑤, and then add the above chemical pickling solution to the present invention The tank body of the derusting work area of the device ③. The workpiece is a hanger basket equipped with a small steel mold with scale, which is put into the workpiece track 11 of the device of the present invention, and the device automatically derusts and regenerates. After derusting, hang it down for use.

Embodiment 2

[0051] The present invention "a safe and environment-friendly metal continuous rust removal method and device" provides a metal chemical pickling solution (rust remover), the composition of which includes: 25% hydrochloric acid, 0.3% urea; the purpose of rust removal is to remove rust from steel Oxide skin; derusting process conditions: temperature at normal temperature, time 15min; operation method: first add a certain height of water (sealing liquid) to the tank body ① and tank body ⑤, and then add the above chemical pickling solution to the device of the present invention Tank body in the derusting work area ③. The workpiece is a hanger basket equipped with iron and steel screws with oxidized scales. The hanger basket is placed on the workpiece rail 11 of the device of the present invention, and the device automatically derusts and regenerates. After derusting, hang it down for use.

Embodiment 3

[0053] The present invention "a safe and environment-friendly metal continuous rust removal method and device" provides a metal chemical pickling solution (rust remover), the composition of which includes: 25% sulfuric acid, 8% hydrochloric acid, 0.3% thiourea, urethane Lotropine 0.2%; the purpose of rust removal is to remove scale from steel; rust removal process conditions: temperature at normal temperature, time 30min; operation method: first add a certain height of water (sealing liquid) to the tank body ① and tank body ⑤, and then Add above-mentioned chemical pickling liquid to the derusting working area tank body 3. of the device of the present invention again. The workpiece is a hanger rack equipped with a steel pipe with scale, and the hanger rack is placed on the workpiece track 11 of the device of the present invention, and the device automatically derusts and regenerates. After derusting, hang it down for use.

[0054] The present invention can quickly remove light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com