Polyvinylpyrrolidone cathode interface layer prepared by adsorption method and its application

A polyvinylpyrrolidone and cathode interface layer technology, which can be used in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve problems such as affecting the photoelectric conversion ability of the device, affecting the performance of OSC, and reducing the luminous flux of the active layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

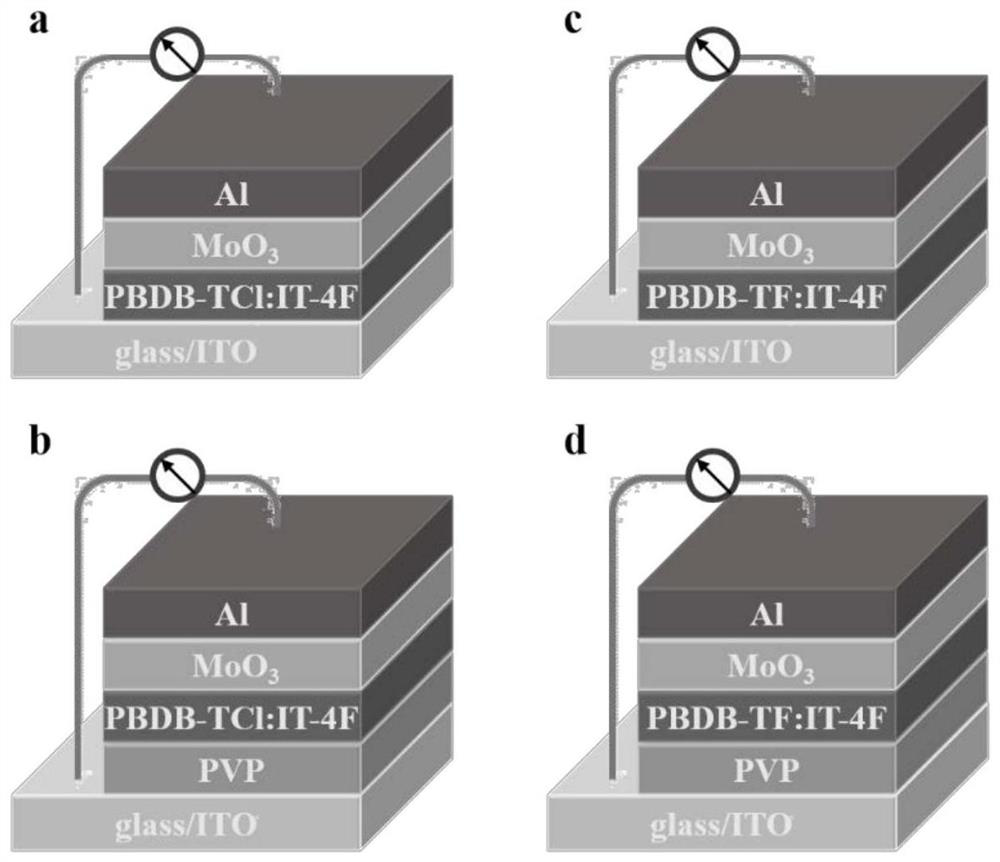

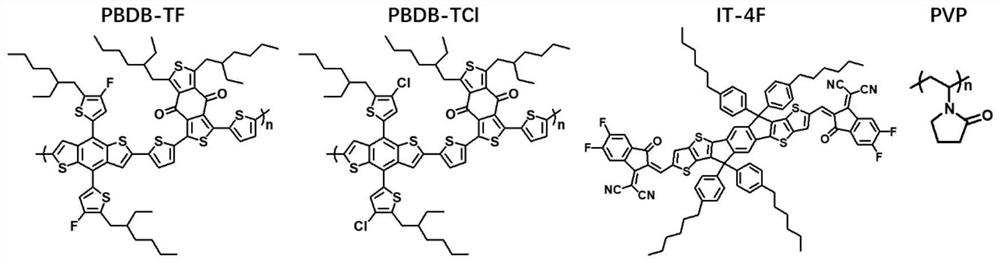

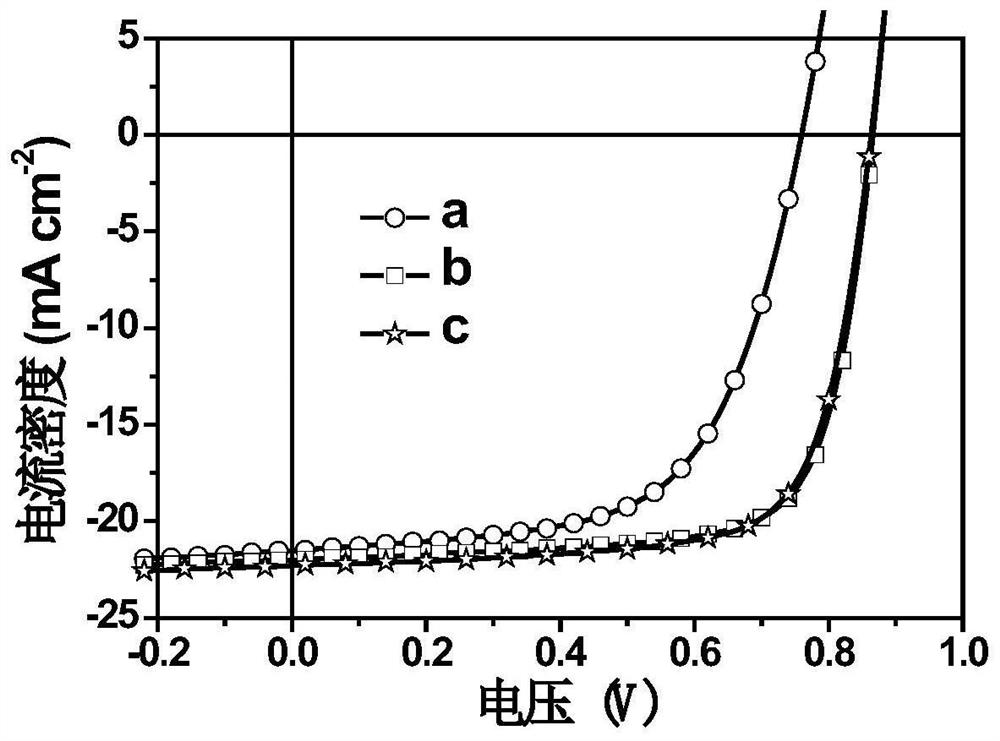

[0050]Example 1 Preparation of solar cells based on PBDB-TCL and using a PVP cathode interface layer (adsorption method)

[0051]0.05 mg of polyvinylpyrrolidone (molecular weight is 360000; the molecular weight distribution index is 1 to 50) to 1 ml of chlorobenzene, stirred and dissolved, i.e., PVP solution.

[0052]10 mg of PBDB-TCl was added to 1 ml of chlorobenzene with 10 mg of IT-4F, and stirred at 40 ° C for 8 h, then 0.5 ml of the PVP solution and 0.5 mL of diiododeane, continued at 40 ° C for 30 min, i.e., to obtain an active layer solution.

[0053]The glass covering the ITO was completely immersed in the above PVP solution, and after standing for 2 s, the adhering solution was absorbed, and the residual solution was blown with a drying paper, and the PVP cathode interface layer was obtained.

[0054]Then, the active layer solution was spinned and 10 min was taken at 100 ° C. Finally, approximately 10-4The pressure of the PA is deposited by 10 nm molybdenum oxide and 100 nm aluminum e...

Embodiment 2

[0067]Example 2 Preparation of solar cells based on PBDB-TF and using a PVP cathode interface layer (adsorption method)

[0068]0.05 mg of polyvinylpyrrolidone (molecular weight is 360000; the molecular weight distribution index is 1 to 50) to 1 ml of chlorobenzene, stirred and dissolved, i.e., PVP solution.

[0069]10 mg of PBDB-TF was added to 1 ml of chlorobenzene with 10 mg of IT-4F, and stirred at 40 ° C for 8 h, then 0.5 mL of the above PVP solution and 0.5 ml of diiododeane, continued at 40 ° C for 30 min, i.e., the active layer solution.

[0070]The glass covering the ITO was completely immersed in the above PVP solution, and after standing for 2 s, the adhering solution was absorbed, and the residual solution was blown with a drying paper, and the PVP cathode interface layer was obtained.

[0071]Then, the active layer solution was spinned and 10 min was taken at 100 ° C. Finally, approximately 10-4The pressure of the PA is deposited by 10 nm molybdenum oxide and 100 nm aluminum electr...

Embodiment 3

[0074]Example 3, Preparation of solar cells of the PVP cathode interface layer using a longer adsorption time

[0075]0.05 mg of polyvinylpyrrolidone (molecular weight is 360000; the molecular weight distribution index is 1 to 50) to 1 ml of chlorobenzene, stirred and dissolved, i.e., PVP solution. 10 mg of PBDB-TF was added to 1 ml of chlorobenzene with 10 mg of IT-4F, and stirred at 40 ° C for 8 h, then 0.5 mL of the above PVP solution and 0.5 ml of diiododeane, continued at 40 ° C for 30 min, i.e., the active layer solution.

[0076]The glass covering the ITO was completely immersed in the above PVP solution, and then taken out after standing for 15 h, and the adhering solution was absorbed with a dust-free paper, and the residual solution was blown with a flap to obtain a PVP cathode interface layer.

[0077]Then, the active layer solution was spinned and 10 min was taken at 100 ° C. Finally, approximately 10-4The pressure of the PA is deposited by 10 nm molybdenum oxide and 100 nm alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com