Kitchen appliance containing cover closing safety protection linkage assembly and control method of kitchen appliance

A technology for kitchen utensils and linkage components, which is applied in the directions of kitchen utensils, program control, computer control, etc., can solve the problems of difficult cleaning, difficult installation, and inability to detect the installation of the mixing cup, so as to reduce the probability of mechanical danger and reduce mechanical Hazard probability, the effect of reducing the chance of mechanical hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

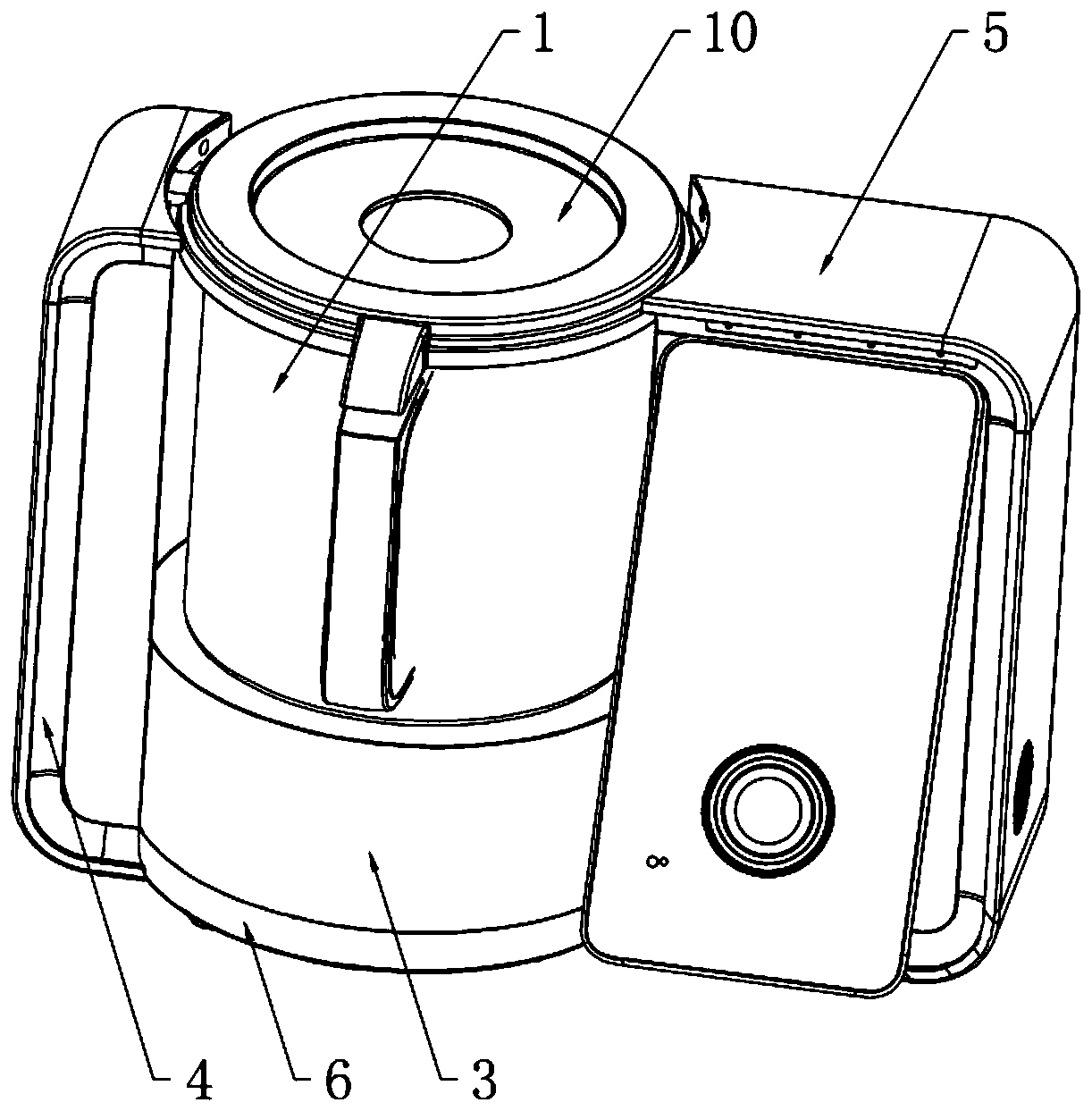

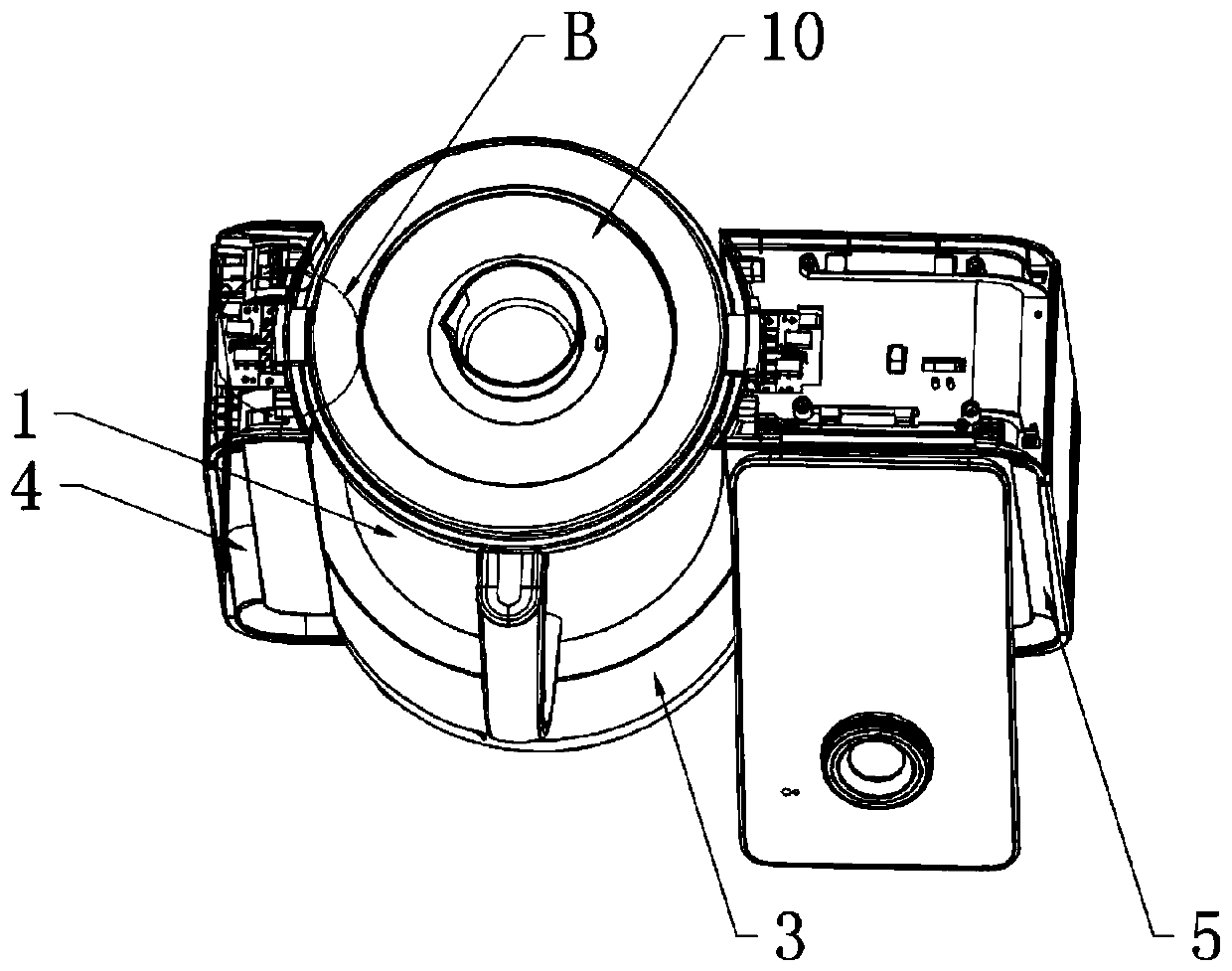

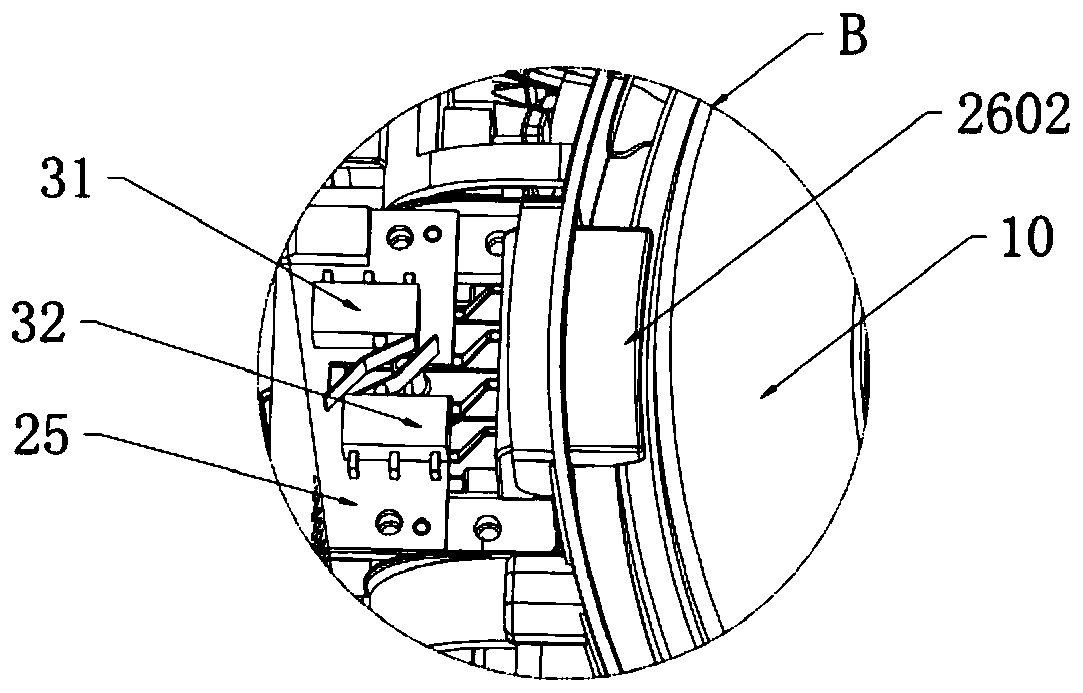

[0089] A kitchen appliance including a lid closing safety protection linkage assembly, comprising an installation shell 1, a main body shell 3 equipped with a switched reluctance motor 2 inside, a handle shell 4 fixedly connected to both sides of the main body shell 3, and a control shell 5. And the base 6 assembled on the lower end of the host housing 3, the handle housing 4, and the control housing 5. The control housing 5 is equipped with a PCB board 7 and a micro control unit MCU for controlling the work of the kitchen appliance; the host housing The upper end of 3 is formed with a housing bracket 8 for assembling the installation housing 1, and the installation housing 1 is equipped with a container assembly, and the container assembly includes a heating container 9, a container cover 10 fastened on the heating container 9, A container in-position detection structure is provided between the container assembly, the installation shell 1, and the shell bracket 8. The handle s...

Embodiment 2

[0101] Embodiment 2 of the present invention is further improved on the basis of Embodiment 1, so as to fully exert the technical advantages of the present invention, which will be illustrated below.

[0102] For example, the heating container 9 is also provided with a stirring assembly for food stirring, and the stirring assembly includes an arc cutter 23 matched with the bottom of the heating container, and the lower end of the arc cutter 23 is connected to the switched reluctance motor 2 drive connections. The arc cutter 23 drives the food to stir / stir in the process of rotation, which not only helps to improve the stirring performance of the food, but also prevents the bottom of the heating container 9 from sticking. The lower end of the cutter shaft of the arc cutter 23 passes through the connecting portion It is connected with the motor shaft of the switched reluctance motor 2, and the detachable function of the stirring assembly can be realized through the connection of...

Embodiment 3

[0106] Embodiment 3 of the present invention is further improved on the basis of Embodiment 1 so as to fully exert the technical advantages of the present invention, which will be illustrated below.

[0107] For example: the exterior of the control shell is equipped with an angle-adjustable display screen assembly 61, which can adjust the inclination angle of the display screen assembly 61 according to the user's height and usage habits. The display screen assembly 61 includes a display screen shell, a display screen, a knob, And the display screen electronic board located in the display screen housing, the display screen and the knob are electrically connected to the display screen electronic board respectively, the display screen electronic board is electrically connected to the micro control unit MCU, and the required setting is adjusted by rotating the knob The time, temperature, speed, weight, etc. of the device are displayed on the display screen. Between the handle shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com