Ultralow-warpage high-strength long glass fiber reinforced polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of long glass fiber reinforced polypropylene composite material and its preparation, can solve the problems of reducing the strength of the material, and achieve the effects of improving the strength, being easy to form and processing, and enhancing the bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

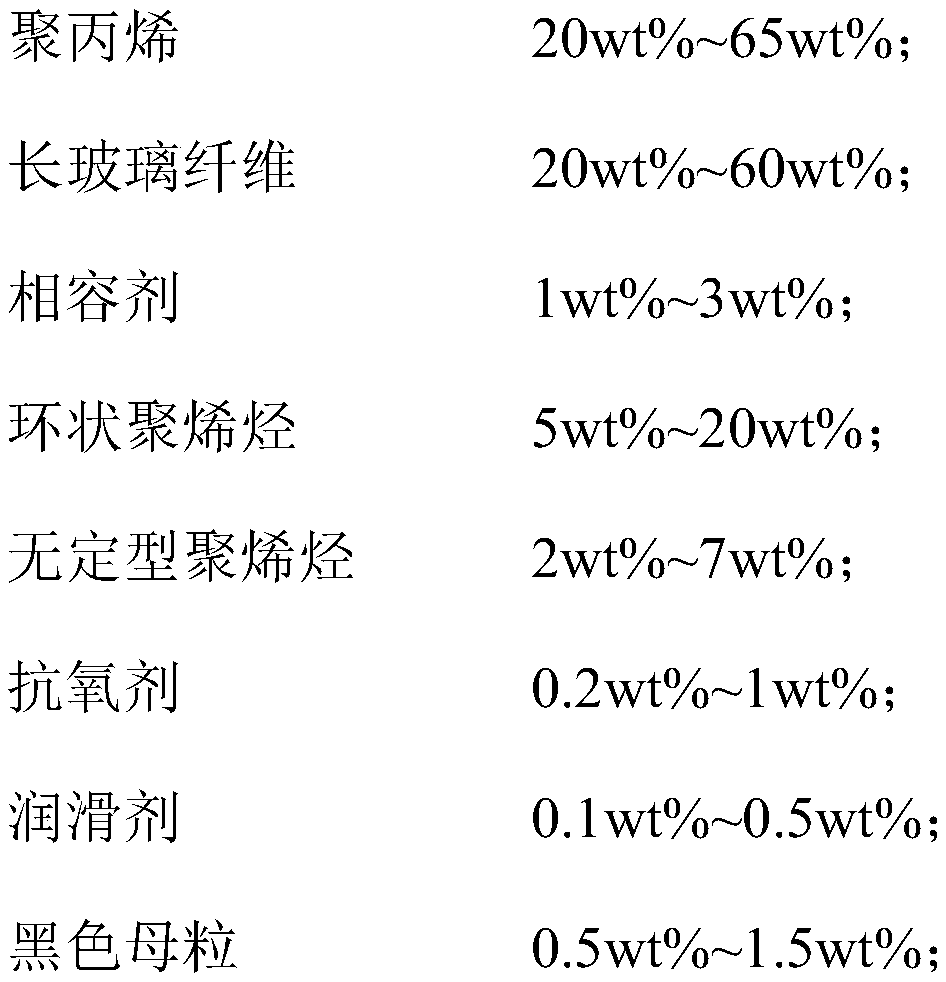

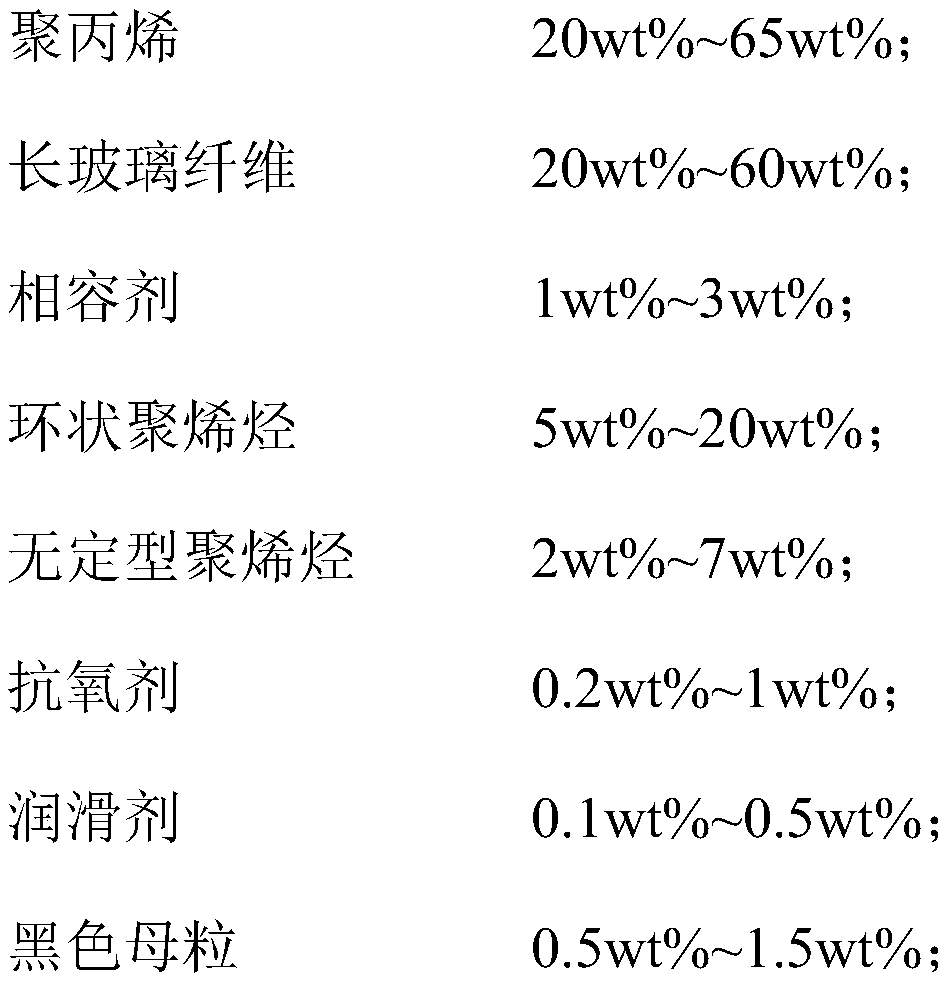

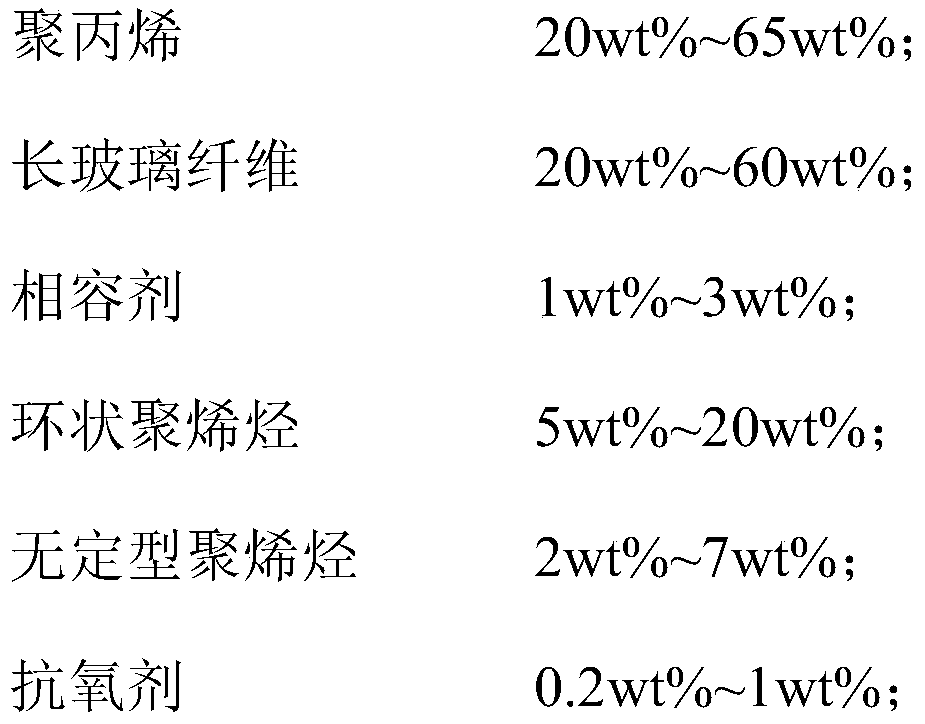

[0035] The present invention also provides a preparation method of long glass fiber reinforced polypropylene composite material, comprising:

[0036] 20wt%-65wt% polypropylene; 5wt%-20wt% cyclic polyolefin; 2wt%-7wt% amorphous polyolefin; 0.2wt%-1wt% antioxidant; 0.1wt%-0.5wt% lubricant; 1wt% to 3wt% compatibilizer; 0.5wt% to 1.5wt% black masterbatch mixed to obtain a mixed material;

[0037] The mixed material is prepared by a melting method to obtain a long glass fiber reinforced polypropylene composite material.

[0038] Specifically: melt extrusion after mixing polypropylene, cyclic polyolefin, amorphous polyolefin APAO, antioxidant, lubricant, compatibilizer and black masterbatch to obtain a melt; extrude the melt into In the impregnation mold, the long glass fiber is impregnated with the melt through the impregnation mold, cooled and pelletized to obtain the long glass fiber reinforced polypropylene composite material.

[0039]In the following process of preparing long...

Embodiment 1~3

[0042] A long glass fiber reinforced polypropylene composite material with ultra-low warpage and high strength, its raw material formula is as shown in table 1, wherein the long glass fiber treatment agent is a glycidyl methacrylate type graft, and its preparation method includes the following step:

[0043] Mix materials other than glass fibers and then melt and extrude to obtain a melt; then extrude the melt into an impregnation mold, impregnate long glass fibers with the melt through the impregnation mold, cool and granulate Finally, an ultra-low warpage and high-strength long glass fiber reinforced polypropylene composite material is obtained.

[0044] The raw material formula (by mass percentage) of the long glass fiber reinforced polypropylene material of table 1 embodiment and comparative example

[0045]

[0046] Polypropylene BJ356AI is a product of Borouge; antioxidant 1010 and 168 are products of BASF; compatibilizer 363ZV-HM4 is a product of Polymer Asia; compa...

Embodiment 4~9

[0069] A long glass fiber reinforced polypropylene composite material with ultra-low warpage and high strength, its raw material formula is as shown in table 3, wherein the long glass fiber treatment agent is a glycidyl methacrylate type graft, and its preparation method includes the following step:

[0070] Mix materials other than glass fibers and then melt and extrude to obtain a melt; then extrude the melt into an impregnation mold, impregnate long glass fibers with the melt through the impregnation mold, cool and granulate Finally, an ultra-low warpage and high-strength long glass fiber reinforced polypropylene composite material is obtained.

[0071] The raw material formula (by mass percentage) of the long glass fiber reinforced polypropylene material in table 3 embodiment 4~9

[0072]

[0073] In table 3, described antioxidant can also be selected from one or more in aromatic amine antioxidant, hindered phenolic antioxidant and phosphite antioxidant; Described lubr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com